Are you a seasoned Extruding Press Operator seeking a new career path? Discover our professionally built Extruding Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

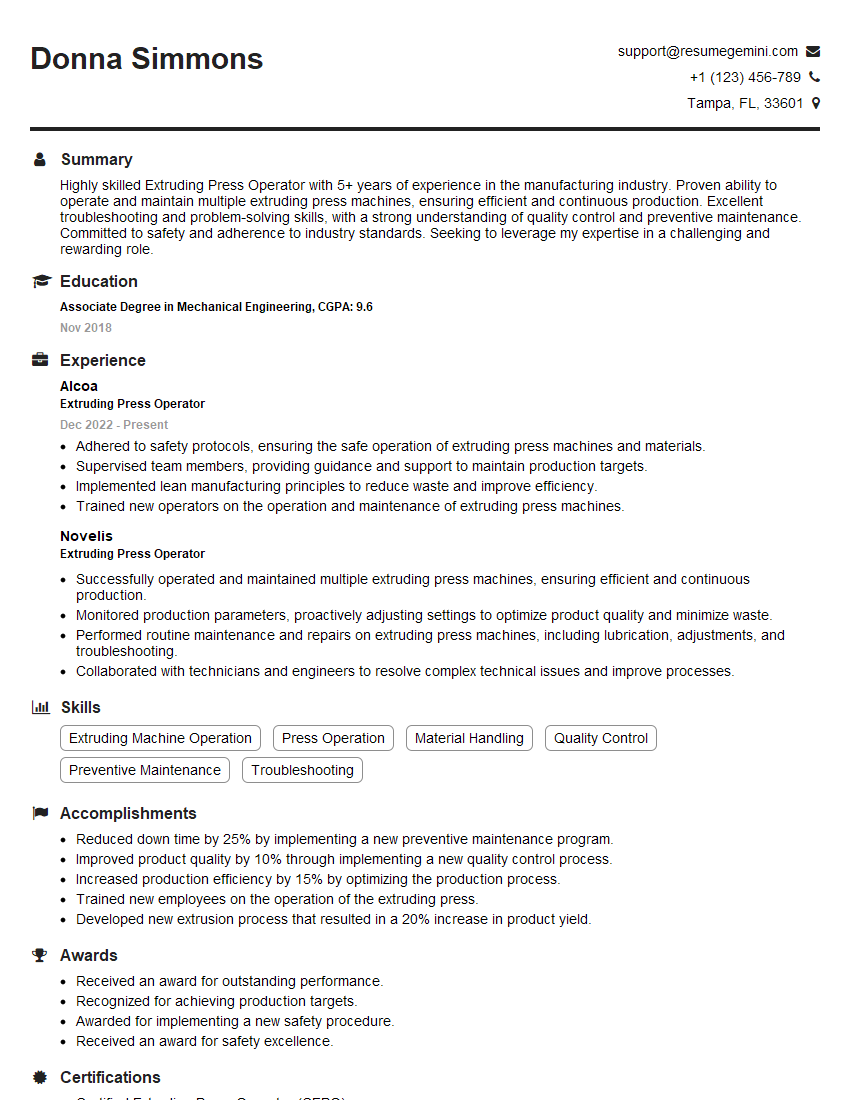

Donna Simmons

Extruding Press Operator

Summary

Highly skilled Extruding Press Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate and maintain multiple extruding press machines, ensuring efficient and continuous production. Excellent troubleshooting and problem-solving skills, with a strong understanding of quality control and preventive maintenance. Committed to safety and adherence to industry standards. Seeking to leverage my expertise in a challenging and rewarding role.

Education

Associate Degree in Mechanical Engineering

November 2018

Skills

- Extruding Machine Operation

- Press Operation

- Material Handling

- Quality Control

- Preventive Maintenance

- Troubleshooting

Work Experience

Extruding Press Operator

- Adhered to safety protocols, ensuring the safe operation of extruding press machines and materials.

- Supervised team members, providing guidance and support to maintain production targets.

- Implemented lean manufacturing principles to reduce waste and improve efficiency.

- Trained new operators on the operation and maintenance of extruding press machines.

Extruding Press Operator

- Successfully operated and maintained multiple extruding press machines, ensuring efficient and continuous production.

- Monitored production parameters, proactively adjusting settings to optimize product quality and minimize waste.

- Performed routine maintenance and repairs on extruding press machines, including lubrication, adjustments, and troubleshooting.

- Collaborated with technicians and engineers to resolve complex technical issues and improve processes.

Accomplishments

- Reduced down time by 25% by implementing a new preventive maintenance program.

- Improved product quality by 10% through implementing a new quality control process.

- Increased production efficiency by 15% by optimizing the production process.

- Trained new employees on the operation of the extruding press.

- Developed new extrusion process that resulted in a 20% increase in product yield.

Awards

- Received an award for outstanding performance.

- Recognized for achieving production targets.

- Awarded for implementing a new safety procedure.

- Received an award for safety excellence.

Certificates

- Certified Extruding Press Operator (CEPO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Extruding Press Operator

- Highlight your experience and skills in operating and maintaining extruding press machines.

- Showcase your troubleshooting and problem-solving abilities, providing specific examples of how you resolved technical issues.

- Emphasize your understanding of quality control and preventive maintenance practices.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency and product quality.

Essential Experience Highlights for a Strong Extruding Press Operator Resume

- Operated and maintained multiple extruding press machines, ensuring optimal performance and productivity.

- Monitored production parameters, proactively adjusting settings to maintain product quality and minimize waste.

- Performed routine maintenance and repairs on extruding press machines, including lubrication, adjustments, and troubleshooting.

- Collaborated with technicians and engineers to resolve complex technical issues and improve processes.

- Adhered to safety protocols, ensuring the safe operation of extruding press machines and materials.

- Trained new operators on the operation and maintenance of extruding press machines.

Frequently Asked Questions (FAQ’s) For Extruding Press Operator

What is the primary role of an Extruding Press Operator?

The primary role of an Extruding Press Operator is to operate and maintain extruding press machines, ensuring continuous and efficient production of extruded products.

What are the essential skills required to be an Extruding Press Operator?

Essential skills include operating extruding press machines, understanding production parameters, performing routine maintenance and repairs, troubleshooting technical issues, and adhering to safety protocols.

What is the work environment like for an Extruding Press Operator?

Extruding Press Operators typically work in industrial settings, operating machines in production facilities. The work can be physically demanding and may involve exposure to noise, dust, and other potential hazards.

What are the career advancement opportunities for Extruding Press Operators?

With experience, Extruding Press Operators can advance to supervisory roles, such as Extruding Press Lead or Supervisor. They may also specialize in specific areas, such as quality control or maintenance.

What are the key qualities that make a successful Extruding Press Operator?

Successful Extruding Press Operators are detail-oriented, have strong mechanical aptitude, and are able to work independently and as part of a team. They must also be committed to safety and continuous improvement.