Are you a seasoned Forming Machine Operator seeking a new career path? Discover our professionally built Forming Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

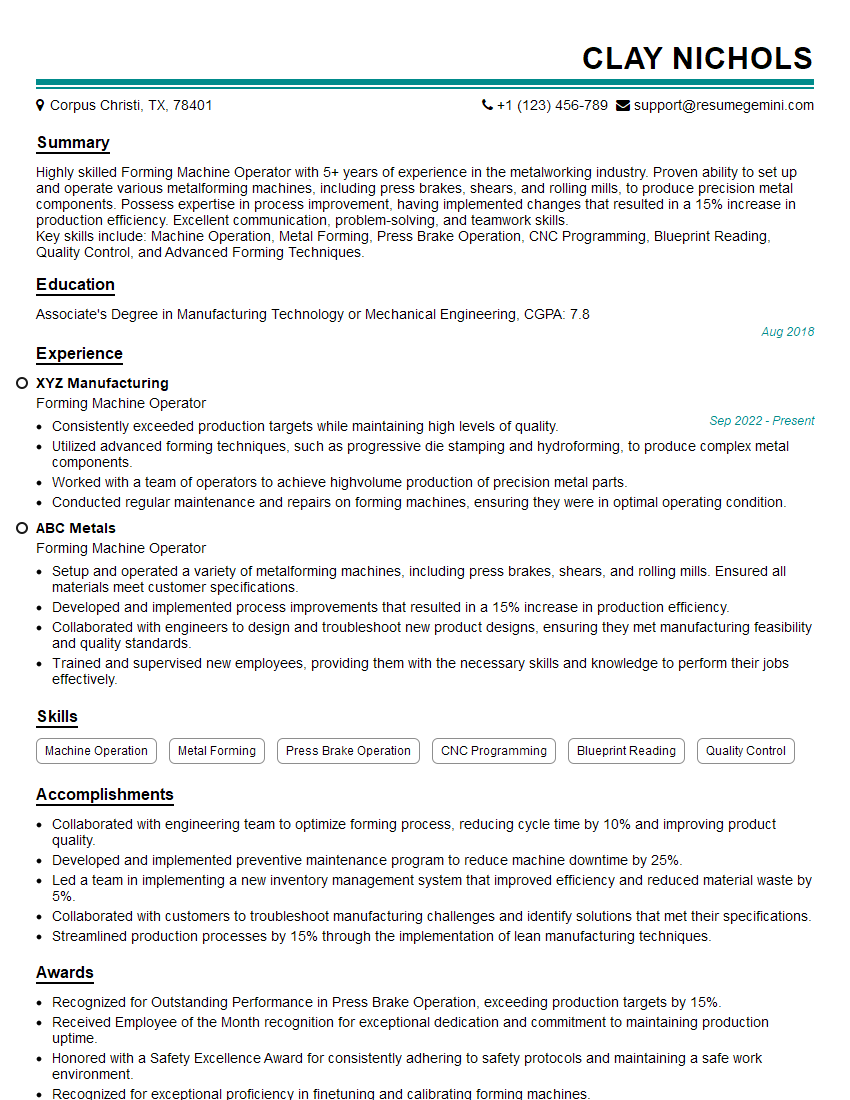

Clay Nichols

Forming Machine Operator

Summary

Highly skilled Forming Machine Operator with 5+ years of experience in the metalworking industry. Proven ability to set up and operate various metalforming machines, including press brakes, shears, and rolling mills, to produce precision metal components. Possess expertise in process improvement, having implemented changes that resulted in a 15% increase in production efficiency. Excellent communication, problem-solving, and teamwork skills.

Key skills include: Machine Operation, Metal Forming, Press Brake Operation, CNC Programming, Blueprint Reading, Quality Control, and Advanced Forming Techniques.

Education

Associate’s Degree in Manufacturing Technology or Mechanical Engineering

August 2018

Skills

- Machine Operation

- Metal Forming

- Press Brake Operation

- CNC Programming

- Blueprint Reading

- Quality Control

Work Experience

Forming Machine Operator

- Consistently exceeded production targets while maintaining high levels of quality.

- Utilized advanced forming techniques, such as progressive die stamping and hydroforming, to produce complex metal components.

- Worked with a team of operators to achieve highvolume production of precision metal parts.

- Conducted regular maintenance and repairs on forming machines, ensuring they were in optimal operating condition.

Forming Machine Operator

- Setup and operated a variety of metalforming machines, including press brakes, shears, and rolling mills. Ensured all materials meet customer specifications.

- Developed and implemented process improvements that resulted in a 15% increase in production efficiency.

- Collaborated with engineers to design and troubleshoot new product designs, ensuring they met manufacturing feasibility and quality standards.

- Trained and supervised new employees, providing them with the necessary skills and knowledge to perform their jobs effectively.

Accomplishments

- Collaborated with engineering team to optimize forming process, reducing cycle time by 10% and improving product quality.

- Developed and implemented preventive maintenance program to reduce machine downtime by 25%.

- Led a team in implementing a new inventory management system that improved efficiency and reduced material waste by 5%.

- Collaborated with customers to troubleshoot manufacturing challenges and identify solutions that met their specifications.

- Streamlined production processes by 15% through the implementation of lean manufacturing techniques.

Awards

- Recognized for Outstanding Performance in Press Brake Operation, exceeding production targets by 15%.

- Received Employee of the Month recognition for exceptional dedication and commitment to maintaining production uptime.

- Honored with a Safety Excellence Award for consistently adhering to safety protocols and maintaining a safe work environment.

- Recognized for exceptional proficiency in finetuning and calibrating forming machines.

Certificates

- Certified Forming Machine Operator (CFMO)

- National Institute for Metalworking Skills (NIMS) Credential

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forming Machine Operator

- Highlight your skills and experience in operating forming machines. Quantify your accomplishments whenever possible, such as increasing production efficiency or reducing scrap rates.

- Showcase your knowledge of metalworking processes and techniques. Use industry-specific terminology and demonstrate your understanding of different types of metals and forming methods.

- Emphasize your attention to detail and quality control. Provide examples of how you ensure the accuracy and precision of metal parts produced.

- Highlight your safety??. Explain how you follow safety protocols and procedures to maintain a safe work environment.

Essential Experience Highlights for a Strong Forming Machine Operator Resume

- Set up and operate press brakes, shears, rolling mills, and other metalforming machines to produce metal parts and components.

- Interpret blueprints and work orders to determine the required specifications for metal parts.

- Inspect finished parts to ensure they meet quality standards and customer requirements.

- Troubleshoot and resolve operational issues with forming machines and equipment.

- Maintain a clean and organized work area, following safety protocols and procedures.

- Collaborate with engineers and production staff to improve processes and ensure production efficiency.

- Train and supervise new employees on forming machine operation and safety procedures.

Frequently Asked Questions (FAQ’s) For Forming Machine Operator

What are the key skills required for a Forming Machine Operator?

Machine Operation, Metal Forming, Press Brake Operation, CNC Programming, Blueprint Reading, Quality Control, and Advanced Forming Techniques.

What are the responsibilities of a Forming Machine Operator?

Setting up and operating metalforming machines, inspecting finished parts, troubleshooting operational issues, maintaining a clean work area, and collaborating with engineers and production staff.

What industries employ Forming Machine Operators?

Automotive, aerospace, construction, and manufacturing industries.

What is the average salary for a Forming Machine Operator?

The average salary for a Forming Machine Operator in the United States is around $45,000 per year.

What are the career advancement opportunities for a Forming Machine Operator?

With experience and additional training, Forming Machine Operators can advance to positions such as Machine Shop Supervisor, Production Manager, or Quality Control Manager.

What are the educational requirements for a Forming Machine Operator?

While no formal education is required, most employers prefer candidates with at least a high school diploma or equivalent and some experience in metalworking or manufacturing.

What are the physical demands of a Forming Machine Operator?

Forming Machine Operators must be able to stand for long periods, lift heavy objects, and operate machinery in a noisy environment.