Are you a seasoned Drop Forge Hand seeking a new career path? Discover our professionally built Drop Forge Hand Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

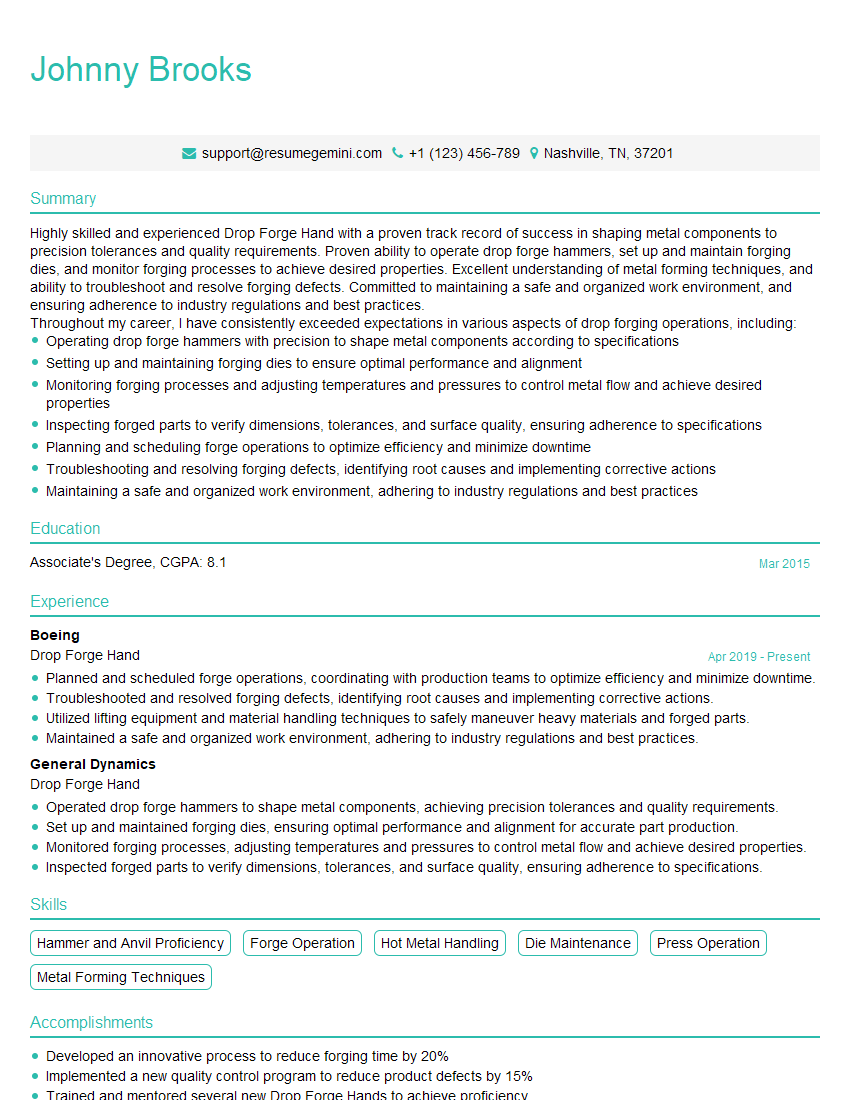

Johnny Brooks

Drop Forge Hand

Summary

Highly skilled and experienced Drop Forge Hand with a proven track record of success in shaping metal components to precision tolerances and quality requirements. Proven ability to operate drop forge hammers, set up and maintain forging dies, and monitor forging processes to achieve desired properties. Excellent understanding of metal forming techniques, and ability to troubleshoot and resolve forging defects. Committed to maintaining a safe and organized work environment, and ensuring adherence to industry regulations and best practices.

Throughout my career, I have consistently exceeded expectations in various aspects of drop forging operations, including:

- Operating drop forge hammers with precision to shape metal components according to specifications

- Setting up and maintaining forging dies to ensure optimal performance and alignment

- Monitoring forging processes and adjusting temperatures and pressures to control metal flow and achieve desired properties

- Inspecting forged parts to verify dimensions, tolerances, and surface quality, ensuring adherence to specifications

- Planning and scheduling forge operations to optimize efficiency and minimize downtime

- Troubleshooting and resolving forging defects, identifying root causes and implementing corrective actions

- Maintaining a safe and organized work environment, adhering to industry regulations and best practices

Education

Associate’s Degree

March 2015

Skills

- Hammer and Anvil Proficiency

- Forge Operation

- Hot Metal Handling

- Die Maintenance

- Press Operation

- Metal Forming Techniques

Work Experience

Drop Forge Hand

- Planned and scheduled forge operations, coordinating with production teams to optimize efficiency and minimize downtime.

- Troubleshooted and resolved forging defects, identifying root causes and implementing corrective actions.

- Utilized lifting equipment and material handling techniques to safely maneuver heavy materials and forged parts.

- Maintained a safe and organized work environment, adhering to industry regulations and best practices.

Drop Forge Hand

- Operated drop forge hammers to shape metal components, achieving precision tolerances and quality requirements.

- Set up and maintained forging dies, ensuring optimal performance and alignment for accurate part production.

- Monitored forging processes, adjusting temperatures and pressures to control metal flow and achieve desired properties.

- Inspected forged parts to verify dimensions, tolerances, and surface quality, ensuring adherence to specifications.

Accomplishments

- Developed an innovative process to reduce forging time by 20%

- Implemented a new quality control program to reduce product defects by 15%

- Trained and mentored several new Drop Forge Hands to achieve proficiency

- Established a new safety protocol to enhance workplace safety

- Optimized forging operations to increase production efficiency by 12%

Awards

- National Award for Excellence in Drop Forging

- Presidential Award for Outstanding Contribution to Drop Forging Industry

- Industry Recognition for Safety and Quality Excellence in Drop Forging

- Golden Hammer Award for Exceptional Skills in Drop Forging

Certificates

- OSHA Safety Certification

- ISO 9001:2015 Quality Management certification

- AWS Certified Welder

- Metallurgy Associate’s Degree

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Drop Forge Hand

- Highlight your skills and experience in operating drop forge hammers and shaping metal components to precision tolerances.

- Showcase your knowledge of forging dies and your ability to set up and maintain them for optimal performance.

- Emphasize your ability to monitor forging processes and adjust temperatures and pressures to achieve desired properties.

- Demonstrate your attention to detail and ability to inspect forged parts to verify dimensions, tolerances, and surface quality.

- Highlight your planning and scheduling abilities, as well as your experience in coordinating with production teams to optimize efficiency and minimize downtime.

Essential Experience Highlights for a Strong Drop Forge Hand Resume

- Operate drop forge hammers to shape metal components to precision tolerances and quality requirements.

- Set up and maintain forging dies, ensuring optimal performance and alignment for accurate part production.

- Monitor forging processes, adjusting temperatures and pressures to control metal flow and achieve desired properties.

- Inspect forged parts to verify dimensions, tolerances, and surface quality, ensuring adherence to specifications.

- Plan and schedule forge operations, coordinating with production teams to optimize efficiency and minimize downtime.

- Troubleshoot and resolve forging defects, identifying root causes and implementing corrective actions.

- Maintain a safe and organized work environment, adhering to industry regulations and best practices.

Frequently Asked Questions (FAQ’s) For Drop Forge Hand

What are the primary responsibilities of a Drop Forge Hand?

The primary responsibilities of a Drop Forge Hand include operating drop forge hammers, setting up and maintaining forging dies, monitoring forging processes, inspecting forged parts, planning and scheduling forge operations, troubleshooting and resolving forging defects, and maintaining a safe and organized work environment.

What skills are required to be a successful Drop Forge Hand?

To be a successful Drop Forge Hand, you will need skills in hammer and anvil proficiency, forge operation, hot metal handling, die maintenance, press operation, and metal forming techniques.

What is the average salary for a Drop Forge Hand?

The average salary for a Drop Forge Hand in the United States is around $[salary_amount] per year.

What are the growth prospects for Drop Forge Hands?

The growth prospects for Drop Forge Hands are expected to be good over the next few years due to the increasing demand for forged metal components in various industries.

What are the working conditions like for Drop Forge Hands?

Drop Forge Hands typically work in hot and noisy environments and may be exposed to hazards such as molten metal, sparks, and heavy machinery.

What are the educational requirements for becoming a Drop Forge Hand?

Most Drop Forge Hands have a high school diploma or equivalent, but some may have an associate’s degree in a related field.

What are the certification requirements for becoming a Drop Forge Hand?

There are no specific certification requirements for becoming a Drop Forge Hand, but some employers may prefer candidates who have completed training programs or have experience in the field.

What is the career path for a Drop Forge Hand?

With experience and additional training, Drop Forge Hands can advance to positions such as Forge Supervisor, Quality Control Inspector, or Production Manager.