Are you a seasoned Forge Hand seeking a new career path? Discover our professionally built Forge Hand Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

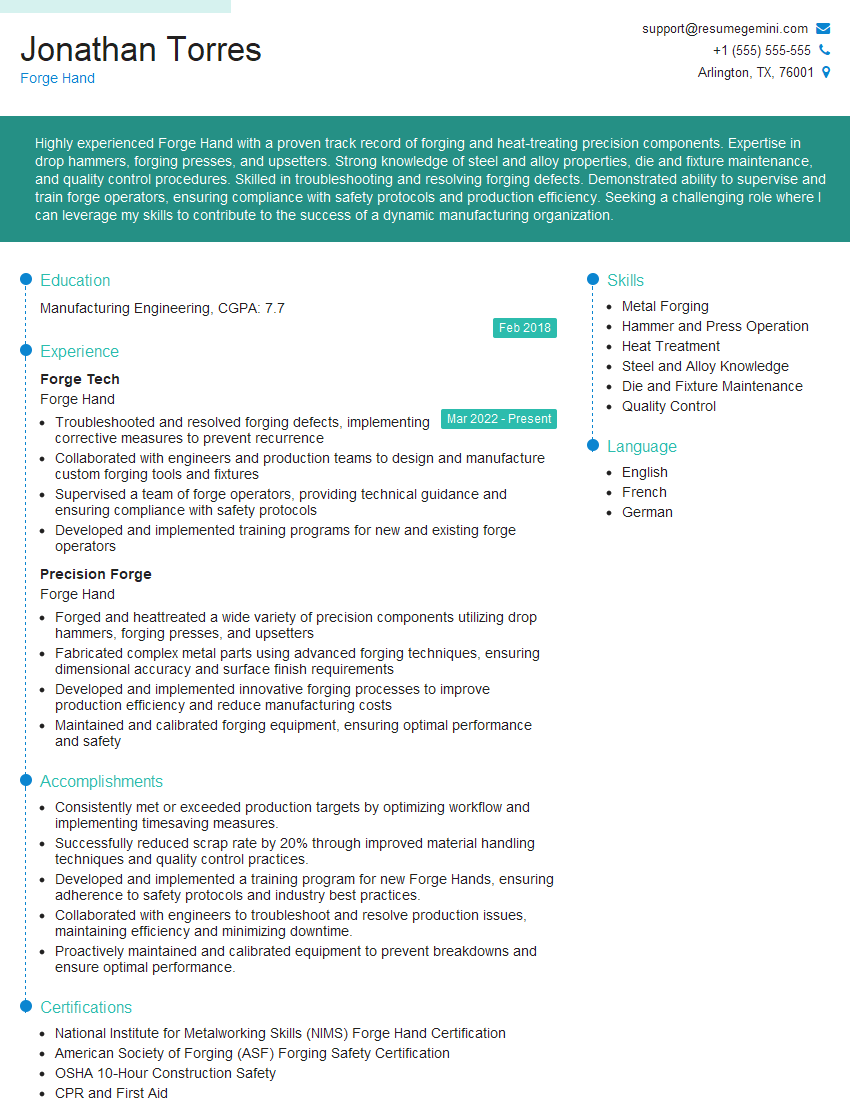

Jonathan Torres

Forge Hand

Summary

Highly experienced Forge Hand with a proven track record of forging and heat-treating precision components. Expertise in drop hammers, forging presses, and upsetters. Strong knowledge of steel and alloy properties, die and fixture maintenance, and quality control procedures. Skilled in troubleshooting and resolving forging defects. Demonstrated ability to supervise and train forge operators, ensuring compliance with safety protocols and production efficiency. Seeking a challenging role where I can leverage my skills to contribute to the success of a dynamic manufacturing organization.

Education

Manufacturing Engineering

February 2018

Skills

- Metal Forging

- Hammer and Press Operation

- Heat Treatment

- Steel and Alloy Knowledge

- Die and Fixture Maintenance

- Quality Control

Work Experience

Forge Hand

- Troubleshooted and resolved forging defects, implementing corrective measures to prevent recurrence

- Collaborated with engineers and production teams to design and manufacture custom forging tools and fixtures

- Supervised a team of forge operators, providing technical guidance and ensuring compliance with safety protocols

- Developed and implemented training programs for new and existing forge operators

Forge Hand

- Forged and heattreated a wide variety of precision components utilizing drop hammers, forging presses, and upsetters

- Fabricated complex metal parts using advanced forging techniques, ensuring dimensional accuracy and surface finish requirements

- Developed and implemented innovative forging processes to improve production efficiency and reduce manufacturing costs

- Maintained and calibrated forging equipment, ensuring optimal performance and safety

Accomplishments

- Consistently met or exceeded production targets by optimizing workflow and implementing timesaving measures.

- Successfully reduced scrap rate by 20% through improved material handling techniques and quality control practices.

- Developed and implemented a training program for new Forge Hands, ensuring adherence to safety protocols and industry best practices.

- Collaborated with engineers to troubleshoot and resolve production issues, maintaining efficiency and minimizing downtime.

- Proactively maintained and calibrated equipment to prevent breakdowns and ensure optimal performance.

Certificates

- National Institute for Metalworking Skills (NIMS) Forge Hand Certification

- American Society of Forging (ASF) Forging Safety Certification

- OSHA 10-Hour Construction Safety

- CPR and First Aid

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forge Hand

- Showcase your skills in forging techniques and knowledge of metallurgy.

- Highlight your experience in using different types of forging equipment.

- Quantify your accomplishments whenever possible, such as reducing production costs or improving efficiency.

- Emphasize your ability to work independently and as part of a team.

- Include relevant keywords throughout your resume to improve its visibility to potential employers.

Essential Experience Highlights for a Strong Forge Hand Resume

- Forged and heat-treated a wide variety of precision components to meet dimensional accuracy and surface finish requirements.

- Developed and implemented innovative forging processes to improve production efficiency and reduce manufacturing costs.

- Collaborated with engineers and production teams to design and manufacture custom forging tools and fixtures.

- Supervised a team of forge operators, providing technical guidance and ensuring compliance with safety protocols.

- Developed and implemented training programs for new and existing forge operators.

- Maintained and calibrated forging equipment to ensure optimal performance and safety.

- Troubleshooted and resolved forging defects, implementing corrective measures to prevent recurrence.

Frequently Asked Questions (FAQ’s) For Forge Hand

What are the primary responsibilities of a Forge Hand?

Forge Hands are responsible for forging and heat-treating metal components using various equipment such as drop hammers, forging presses, and upsetters. They ensure that the components meet the required dimensional accuracy and surface finish, and collaborate with engineers and production teams to design and manufacture custom forging tools and fixtures.

What skills are essential for a successful Forge Hand?

Forge Hands should possess expertise in metal forging, hammer and press operation, heat treatment, steel and alloy knowledge, die and fixture maintenance, and quality control. They should also be proficient in troubleshooting and resolving forging defects, and have strong communication and teamwork skills.

What is the typical career path for a Forge Hand?

Forge Hands can advance to supervisory roles such as Forge Lead or Forge Manager. With additional training and experience, they may also specialize in areas such as tool and die making or metallurgy.

What are the safety precautions that Forge Hands must follow?

Forge Hands must adhere to strict safety protocols, including wearing appropriate protective gear, maintaining a clean and organized work area, and following established procedures for handling and operating forging equipment.

How can I improve my chances of getting hired as a Forge Hand?

To increase your chances of getting hired as a Forge Hand, focus on developing your skills in metalworking, forging techniques, and metallurgy. Gain practical experience through internships or apprenticeships, and obtain relevant certifications to demonstrate your proficiency.

What are the common challenges faced by Forge Hands?

Forge Hands may encounter challenges such as working with hazardous materials, exposure to high temperatures and noise levels, and the need to meet tight production deadlines. They must also stay updated with the latest forging technologies and industry best practices.