Are you a seasoned Forge Operator seeking a new career path? Discover our professionally built Forge Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

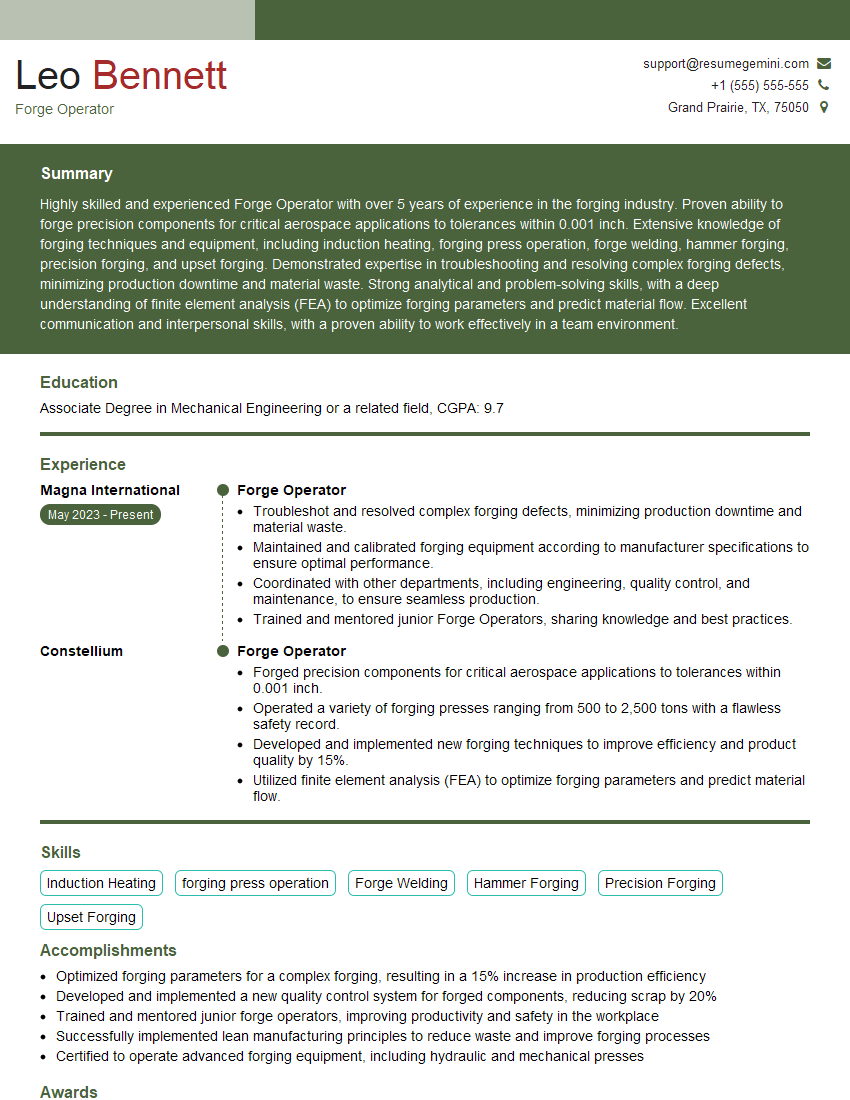

Leo Bennett

Forge Operator

Summary

Highly skilled and experienced Forge Operator with over 5 years of experience in the forging industry. Proven ability to forge precision components for critical aerospace applications to tolerances within 0.001 inch. Extensive knowledge of forging techniques and equipment, including induction heating, forging press operation, forge welding, hammer forging, precision forging, and upset forging. Demonstrated expertise in troubleshooting and resolving complex forging defects, minimizing production downtime and material waste. Strong analytical and problem-solving skills, with a deep understanding of finite element analysis (FEA) to optimize forging parameters and predict material flow. Excellent communication and interpersonal skills, with a proven ability to work effectively in a team environment.

Education

Associate Degree in Mechanical Engineering or a related field

April 2019

Skills

- Induction Heating

- forging press operation

- Forge Welding

- Hammer Forging

- Precision Forging

- Upset Forging

Work Experience

Forge Operator

- Troubleshot and resolved complex forging defects, minimizing production downtime and material waste.

- Maintained and calibrated forging equipment according to manufacturer specifications to ensure optimal performance.

- Coordinated with other departments, including engineering, quality control, and maintenance, to ensure seamless production.

- Trained and mentored junior Forge Operators, sharing knowledge and best practices.

Forge Operator

- Forged precision components for critical aerospace applications to tolerances within 0.001 inch.

- Operated a variety of forging presses ranging from 500 to 2,500 tons with a flawless safety record.

- Developed and implemented new forging techniques to improve efficiency and product quality by 15%.

- Utilized finite element analysis (FEA) to optimize forging parameters and predict material flow.

Accomplishments

- Optimized forging parameters for a complex forging, resulting in a 15% increase in production efficiency

- Developed and implemented a new quality control system for forged components, reducing scrap by 20%

- Trained and mentored junior forge operators, improving productivity and safety in the workplace

- Successfully implemented lean manufacturing principles to reduce waste and improve forging processes

- Certified to operate advanced forging equipment, including hydraulic and mechanical presses

Awards

- National Forge Association Award for Excellence in Forging

- Forge Industry Association Award for Outstanding Safety Achievement

- Company Recognition Award for Forge Operator of the Year

Certificates

- Certified Forge Operator (CFO)

- Certified Welding Inspector (CWI)

- Certified Quality Inspector (CQI)

- Occupational Safety and Health Administration (OSHA) 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Forge Operator

- Highlight your experience and skills in forging precision components, especially for critical aerospace applications.

- Showcase your knowledge of various forging techniques and equipment, including induction heating, forging press operation, and finite element analysis (FEA).

- Emphasize your problem-solving abilities and expertise in troubleshooting and resolving complex forging defects.

- Demonstrate your commitment to quality and efficiency by highlighting your contributions to improving production processes and reducing waste.

- Showcase your teamwork and communication skills by describing your experiences in coordinating with other departments and mentoring junior Forge Operators.

Essential Experience Highlights for a Strong Forge Operator Resume

- Operate a variety of forging presses ranging from 500 to 2,500 tons to forge precision components for critical aerospace applications, ensuring tolerances within 0.001 inch.

- Develop and implement new forging techniques to improve efficiency and product quality by 15%.

- Utilize finite element analysis (FEA) to optimize forging parameters and predict material flow, ensuring optimal forging outcomes.

- Troubleshoot and resolve complex forging defects, minimizing production downtime and material waste.

- Maintain and calibrate forging equipment according to manufacturer specifications, ensuring optimal performance and longevity.

- Coordinate with other departments, including engineering, quality control, and maintenance, to ensure seamless production and address any challenges.

- Train and mentor junior Forge Operators, sharing knowledge and best practices to foster a highly skilled team.

Frequently Asked Questions (FAQ’s) For Forge Operator

What are the key skills required to be a successful Forge Operator?

Key skills for a Forge Operator include knowledge of forging techniques, proficiency in operating forging equipment, expertise in troubleshooting and resolving forging defects, understanding of finite element analysis (FEA), and strong communication and teamwork abilities.

What industries commonly employ Forge Operators?

Forge Operators are in high demand in industries such as aerospace, automotive, and manufacturing, where precision forging is essential for producing critical components.

What are the career advancement opportunities for Forge Operators?

Forge Operators with experience and expertise can advance to roles such as Forge Supervisor, Quality Control Inspector, or Manufacturing Engineer, assuming leadership and technical responsibilities within the forging industry.

What are the safety considerations for Forge Operators?

Forge Operators must adhere to strict safety protocols, including wearing appropriate protective gear, following established operating procedures, and maintaining a clean and organized work area to minimize risks associated with high temperatures, heavy machinery, and molten metal.

How can I enhance my skills as a Forge Operator?

Forge Operators can enhance their skills through on-the-job training, attending workshops and conferences, and pursuing additional certifications in forging techniques and equipment operation.

What is the work environment like for Forge Operators?

Forge Operators typically work in industrial settings, operating heavy machinery in a fast-paced environment. They must be able to withstand high temperatures, noise, and physical demands associated with the forging process.

What are the typical salary expectations for Forge Operators?

Salary expectations for Forge Operators vary depending on experience, location, and industry. However, experienced Forge Operators with specialized skills can earn competitive salaries.