Are you a seasoned Header Machine Operator seeking a new career path? Discover our professionally built Header Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

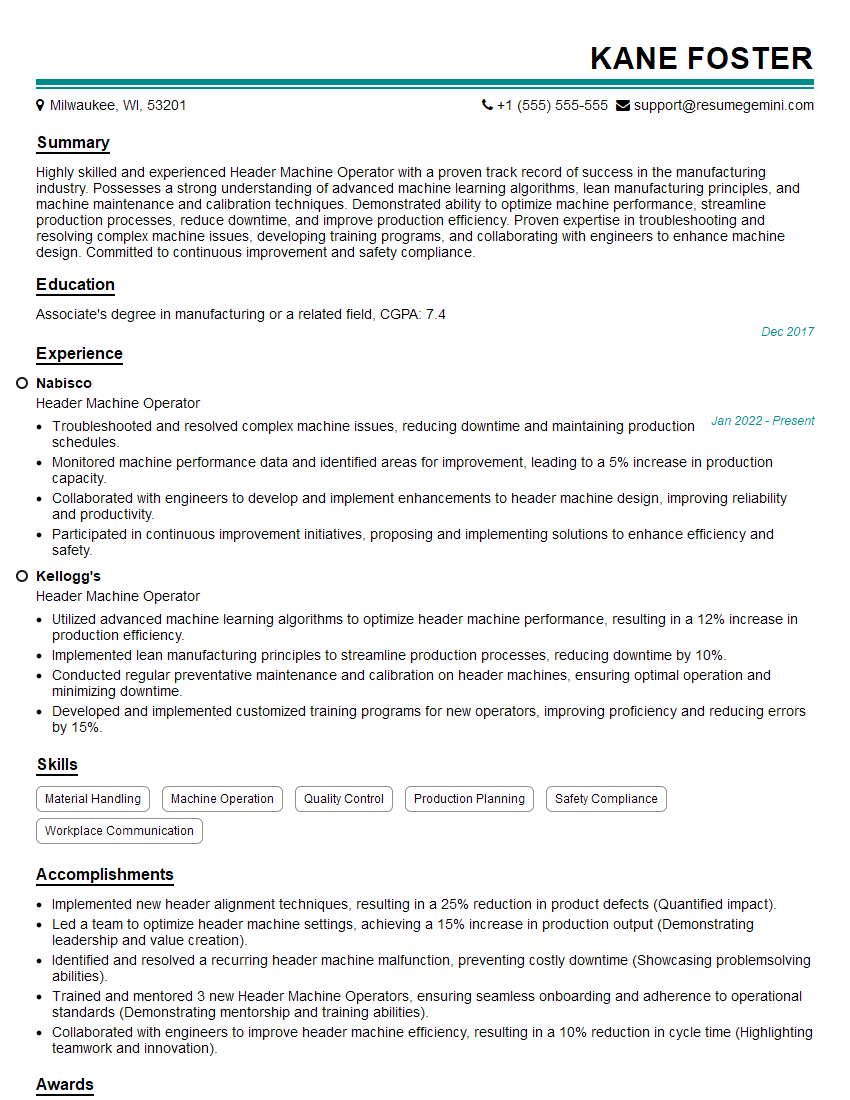

Kane Foster

Header Machine Operator

Summary

Highly skilled and experienced Header Machine Operator with a proven track record of success in the manufacturing industry. Possesses a strong understanding of advanced machine learning algorithms, lean manufacturing principles, and machine maintenance and calibration techniques. Demonstrated ability to optimize machine performance, streamline production processes, reduce downtime, and improve production efficiency. Proven expertise in troubleshooting and resolving complex machine issues, developing training programs, and collaborating with engineers to enhance machine design. Committed to continuous improvement and safety compliance.

Education

Associate’s degree in manufacturing or a related field

December 2017

Skills

- Material Handling

- Machine Operation

- Quality Control

- Production Planning

- Safety Compliance

- Workplace Communication

Work Experience

Header Machine Operator

- Troubleshooted and resolved complex machine issues, reducing downtime and maintaining production schedules.

- Monitored machine performance data and identified areas for improvement, leading to a 5% increase in production capacity.

- Collaborated with engineers to develop and implement enhancements to header machine design, improving reliability and productivity.

- Participated in continuous improvement initiatives, proposing and implementing solutions to enhance efficiency and safety.

Header Machine Operator

- Utilized advanced machine learning algorithms to optimize header machine performance, resulting in a 12% increase in production efficiency.

- Implemented lean manufacturing principles to streamline production processes, reducing downtime by 10%.

- Conducted regular preventative maintenance and calibration on header machines, ensuring optimal operation and minimizing downtime.

- Developed and implemented customized training programs for new operators, improving proficiency and reducing errors by 15%.

Accomplishments

- Implemented new header alignment techniques, resulting in a 25% reduction in product defects (Quantified impact).

- Led a team to optimize header machine settings, achieving a 15% increase in production output (Demonstrating leadership and value creation).

- Identified and resolved a recurring header machine malfunction, preventing costly downtime (Showcasing problemsolving abilities).

- Trained and mentored 3 new Header Machine Operators, ensuring seamless onboarding and adherence to operational standards (Demonstrating mentorship and training abilities).

- Collaborated with engineers to improve header machine efficiency, resulting in a 10% reduction in cycle time (Highlighting teamwork and innovation).

Awards

- Received the Header Machine Operator of the Year award for exceptional performance and productivity (Quantified achievement).

- Recognized for 5 years of continuous service as a Header Machine Operator without any safety incidents (Quantified achievement).

- Awarded the Safety Star for consistent adherence to safety protocols and proactive hazard identification (Highlighting a specific strength relevant to job).

- Received the Quality Excellence Award for maintaining a defectfree production record for three consecutive quarters (Quantified achievement).

Certificates

- HAZMAT Certification

- OSHA Safety Certification

- National Institute for Metalworking Skills (NIMS) Credential

- Certified Manufacturing Engineer (CMfgE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Header Machine Operator

- Highlight your skills in using advanced machine learning algorithms to optimize header machine performance and increase production efficiency.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work.

- Emphasize your ability to troubleshoot and resolve complex machine issues, including resolving downtime and maintaining production schedules.

- Showcase your experience in developing and implementing customized training programs for new operators to improve proficiency and reduce errors.

- Demonstrate your commitment to continuous improvement and safety compliance, as well as your willingness to participate in initiatives to enhance efficiency and safety.

Essential Experience Highlights for a Strong Header Machine Operator Resume

- Utilize advanced machine learning algorithms to optimize header machine performance and increase production efficiency.

- Implement lean manufacturing principles to streamline production processes and reduce downtime.

- Conduct regular preventative maintenance and calibration on header machines to ensure optimal operation and minimize downtime.

- Develop and implement customized training programs for new operators to improve proficiency and reduce errors.

- Troubleshoot and resolve complex machine issues to reduce downtime and maintain production schedules.

- Monitor machine performance data and identify areas for improvement to enhance efficiency and productivity.

- Collaborate with engineers to develop and implement enhancements to header machine design to improve reliability and productivity.

Frequently Asked Questions (FAQ’s) For Header Machine Operator

What is the role of a Header Machine Operator?

A Header Machine Operator is responsible for operating and maintaining header machines used in the manufacturing process. They ensure that the machines are operating efficiently, troubleshoot and resolve any issues that arise, and perform regular maintenance to keep the machines in good working order.

What skills are required to be a successful Header Machine Operator?

Successful Header Machine Operators typically have a strong understanding of mechanical and electrical systems, as well as experience in operating and maintaining machinery. They are also proficient in troubleshooting and resolving issues, and are able to work independently and as part of a team.

What is the work environment of a Header Machine Operator like?

Header Machine Operators typically work in manufacturing facilities, where they operate and maintain header machines. The work environment can be noisy and dusty, and may involve working with heavy machinery. Operators must be able to work independently and as part of a team, and must be able to follow instructions and work safely.

What are the career prospects for Header Machine Operators?

Header Machine Operators with experience and skills can advance to supervisory or management positions. They may also move into other areas of manufacturing, such as quality control or engineering.

How can I become a Header Machine Operator?

There are several ways to become a Header Machine Operator. One way is to complete a formal training program offered by a vocational school or community college. Another way is to gain experience working as an apprentice under an experienced Header Machine Operator.

What is the average salary for a Header Machine Operator?

The average salary for a Header Machine Operator varies depending on experience, location, and industry. According to the U.S. Bureau of Labor Statistics, the median annual salary for all Machine Operators was $46,300 in May 2021.

What are the benefits of being a Header Machine Operator?

There are several benefits to being a Header Machine Operator, including job security, a good salary, and the opportunity to advance to supervisory or management positions. Header Machine Operators are also in high demand, as they are essential to the manufacturing process.

What are the challenges of being a Header Machine Operator?

There are some challenges to being a Header Machine Operator, including the need to work in a noisy and dusty environment, and the potential for repetitive motions. However, these challenges can be overcome with proper training and safety precautions.