Are you a seasoned Heavy Forging Machine Operator seeking a new career path? Discover our professionally built Heavy Forging Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

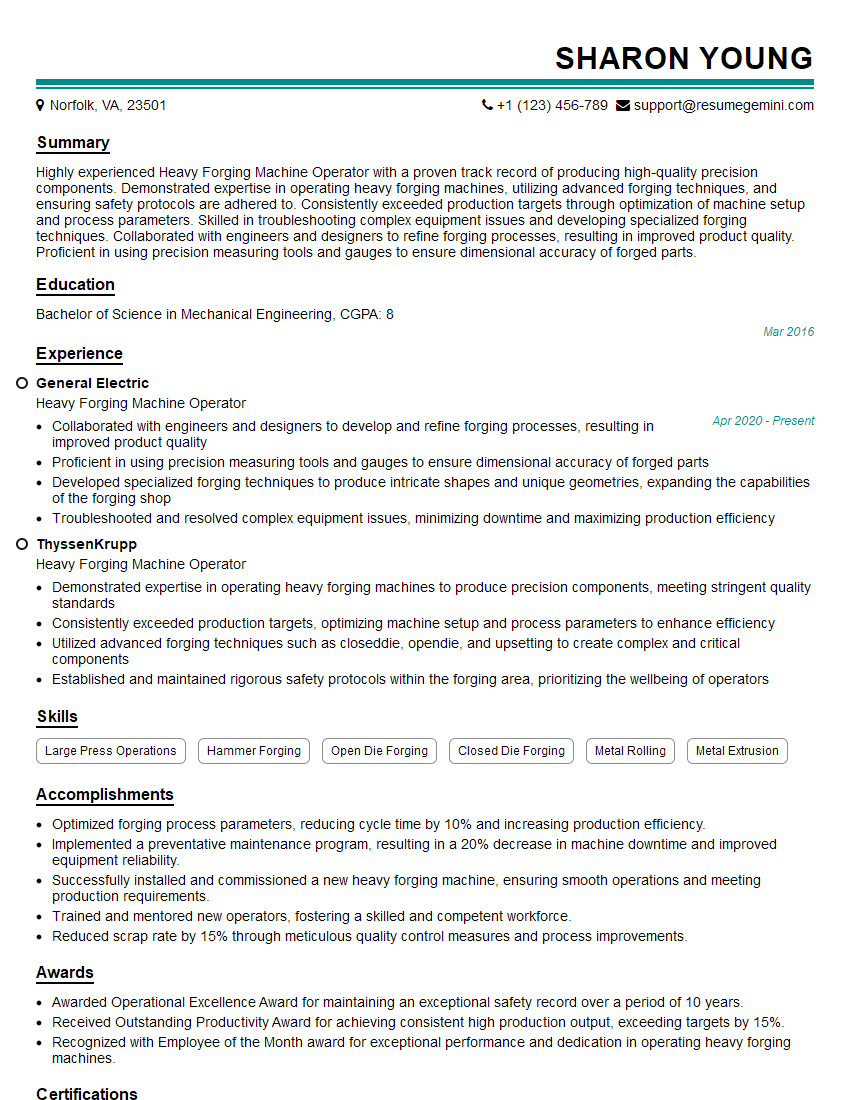

Sharon Young

Heavy Forging Machine Operator

Summary

Highly experienced Heavy Forging Machine Operator with a proven track record of producing high-quality precision components. Demonstrated expertise in operating heavy forging machines, utilizing advanced forging techniques, and ensuring safety protocols are adhered to. Consistently exceeded production targets through optimization of machine setup and process parameters. Skilled in troubleshooting complex equipment issues and developing specialized forging techniques. Collaborated with engineers and designers to refine forging processes, resulting in improved product quality. Proficient in using precision measuring tools and gauges to ensure dimensional accuracy of forged parts.

Education

Bachelor of Science in Mechanical Engineering

March 2016

Skills

- Large Press Operations

- Hammer Forging

- Open Die Forging

- Closed Die Forging

- Metal Rolling

- Metal Extrusion

Work Experience

Heavy Forging Machine Operator

- Collaborated with engineers and designers to develop and refine forging processes, resulting in improved product quality

- Proficient in using precision measuring tools and gauges to ensure dimensional accuracy of forged parts

- Developed specialized forging techniques to produce intricate shapes and unique geometries, expanding the capabilities of the forging shop

- Troubleshooted and resolved complex equipment issues, minimizing downtime and maximizing production efficiency

Heavy Forging Machine Operator

- Demonstrated expertise in operating heavy forging machines to produce precision components, meeting stringent quality standards

- Consistently exceeded production targets, optimizing machine setup and process parameters to enhance efficiency

- Utilized advanced forging techniques such as closeddie, opendie, and upsetting to create complex and critical components

- Established and maintained rigorous safety protocols within the forging area, prioritizing the wellbeing of operators

Accomplishments

- Optimized forging process parameters, reducing cycle time by 10% and increasing production efficiency.

- Implemented a preventative maintenance program, resulting in a 20% decrease in machine downtime and improved equipment reliability.

- Successfully installed and commissioned a new heavy forging machine, ensuring smooth operations and meeting production requirements.

- Trained and mentored new operators, fostering a skilled and competent workforce.

- Reduced scrap rate by 15% through meticulous quality control measures and process improvements.

Awards

- Awarded Operational Excellence Award for maintaining an exceptional safety record over a period of 10 years.

- Received Outstanding Productivity Award for achieving consistent high production output, exceeding targets by 15%.

- Recognized with Employee of the Month award for exceptional performance and dedication in operating heavy forging machines.

Certificates

- Certified Tool and Die Maker

- Certified Manufacturing Technologist

- Certified Quality Assurance Auditor

- AWS Certified Welding Inspector

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Heavy Forging Machine Operator

- Highlight your technical skills and experience in operating heavy forging machines.

- Showcase your understanding of advanced forging techniques and ability to produce complex components.

- Demonstrate your commitment to safety and ability to maintain a safe work environment.

- Emphasize your ability to solve problems and troubleshoot complex equipment issues.

- Provide specific examples of how you have exceeded production targets or improved product quality.

Essential Experience Highlights for a Strong Heavy Forging Machine Operator Resume

- Operate heavy forging machines to produce precision components according to specifications.

- Utilize advanced forging techniques such as closed-die, open-die, and upsetting to create complex and critical components.

- Establish and maintain rigorous safety protocols within the forging area, prioritizing the wellbeing of operators.

- Collaborate with engineers and designers to develop and refine forging processes, resulting in improved product quality.

- Troubleshoot and resolve complex equipment issues, minimizing downtime and maximizing production efficiency.

- Develop specialized forging techniques to produce intricate shapes and unique geometries, expanding the capabilities of the forging shop.

- Proficient in using precision measuring tools and gauges to ensure dimensional accuracy of forged parts.

Frequently Asked Questions (FAQ’s) For Heavy Forging Machine Operator

What are the primary responsibilities of a Heavy Forging Machine Operator?

Operating heavy forging machines to produce precision components, ensuring safety, collaborating with engineers, troubleshooting equipment issues, and developing specialized forging techniques.

What skills are required to become a Heavy Forging Machine Operator?

Expertise in operating heavy forging machines, knowledge of advanced forging techniques, commitment to safety, problem-solving abilities, and proficiency in using precision measuring tools.

What industries employ Heavy Forging Machine Operators?

Automotive, aerospace, construction, and manufacturing industries.

What is the average salary for a Heavy Forging Machine Operator?

The average salary varies depending on experience, location, and industry, but typically ranges from $20 to $30 per hour.

What are the career advancement opportunities for a Heavy Forging Machine Operator?

With experience and additional training, Heavy Forging Machine Operators can advance to positions such as Foreman, Supervisor, or Quality Control Inspector.