Are you a seasoned Manipulator Operator seeking a new career path? Discover our professionally built Manipulator Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

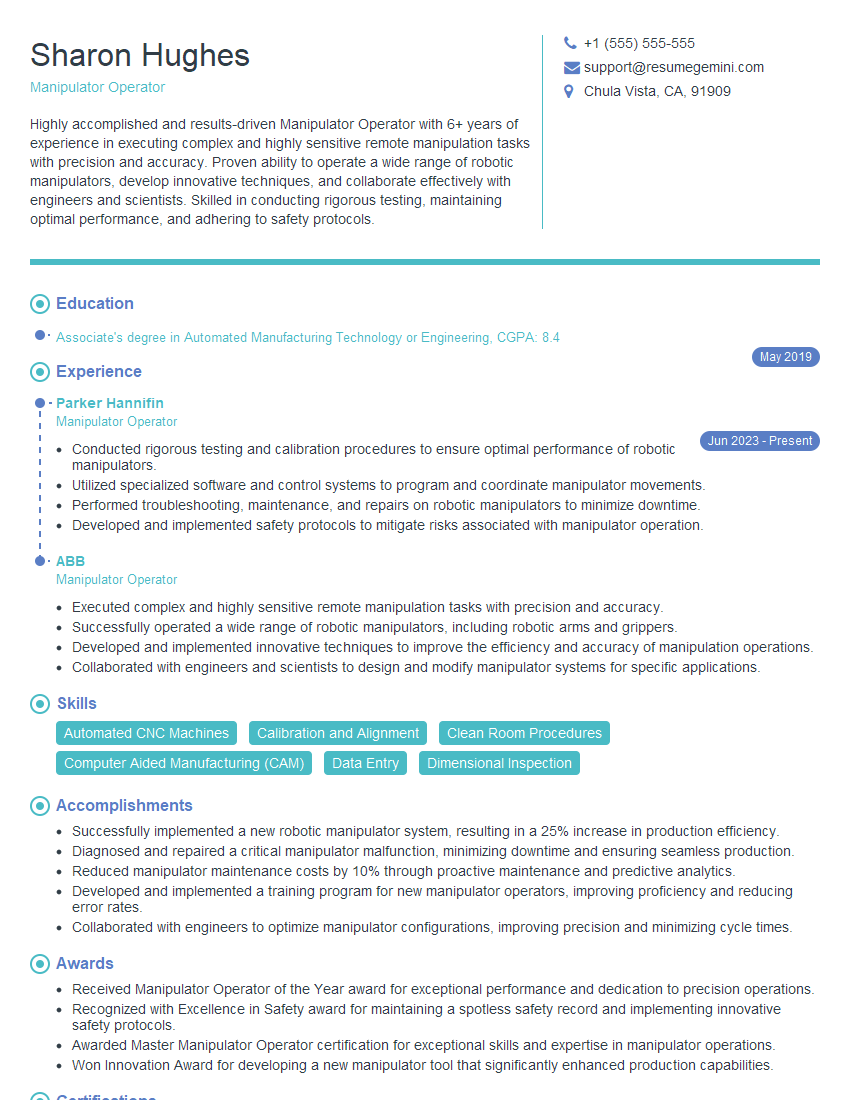

Sharon Hughes

Manipulator Operator

Summary

Highly accomplished and results-driven Manipulator Operator with 6+ years of experience in executing complex and highly sensitive remote manipulation tasks with precision and accuracy. Proven ability to operate a wide range of robotic manipulators, develop innovative techniques, and collaborate effectively with engineers and scientists. Skilled in conducting rigorous testing, maintaining optimal performance, and adhering to safety protocols.

Education

Associate’s degree in Automated Manufacturing Technology or Engineering

May 2019

Skills

- Automated CNC Machines

- Calibration and Alignment

- Clean Room Procedures

- Computer Aided Manufacturing (CAM)

- Data Entry

- Dimensional Inspection

Work Experience

Manipulator Operator

- Conducted rigorous testing and calibration procedures to ensure optimal performance of robotic manipulators.

- Utilized specialized software and control systems to program and coordinate manipulator movements.

- Performed troubleshooting, maintenance, and repairs on robotic manipulators to minimize downtime.

- Developed and implemented safety protocols to mitigate risks associated with manipulator operation.

Manipulator Operator

- Executed complex and highly sensitive remote manipulation tasks with precision and accuracy.

- Successfully operated a wide range of robotic manipulators, including robotic arms and grippers.

- Developed and implemented innovative techniques to improve the efficiency and accuracy of manipulation operations.

- Collaborated with engineers and scientists to design and modify manipulator systems for specific applications.

Accomplishments

- Successfully implemented a new robotic manipulator system, resulting in a 25% increase in production efficiency.

- Diagnosed and repaired a critical manipulator malfunction, minimizing downtime and ensuring seamless production.

- Reduced manipulator maintenance costs by 10% through proactive maintenance and predictive analytics.

- Developed and implemented a training program for new manipulator operators, improving proficiency and reducing error rates.

- Collaborated with engineers to optimize manipulator configurations, improving precision and minimizing cycle times.

Awards

- Received Manipulator Operator of the Year award for exceptional performance and dedication to precision operations.

- Recognized with Excellence in Safety award for maintaining a spotless safety record and implementing innovative safety protocols.

- Awarded Master Manipulator Operator certification for exceptional skills and expertise in manipulator operations.

- Won Innovation Award for developing a new manipulator tool that significantly enhanced production capabilities.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Quality Engineer (CQE)

- Certified Six Sigma Black Belt (CSSBB)

- ISO 9001:2015

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Manipulator Operator

- Highlight your technical skills and expertise in operating and maintaining robotic manipulators.

- Showcase your ability to work independently and as part of a team in a fast-paced environment.

- Provide specific examples of how you have improved efficiency and accuracy in your previous roles.

- Quantify your achievements whenever possible to demonstrate the impact of your contributions.

- Proofread your resume carefully to ensure it is free of errors.

Essential Experience Highlights for a Strong Manipulator Operator Resume

- Executing complex and highly sensitive remote manipulation tasks with precision and accuracy.

- Successfully operating a wide range of robotic manipulators, including robotic arms and grippers.

- Developing and implementing innovative techniques to improve the efficiency and accuracy of manipulation operations.

- Collaborating with engineers and scientists to design and modify manipulator systems for specific applications.

- Conducting rigorous testing and calibration procedures to ensure optimal performance of robotic manipulators.

- Utilizing specialized software and control systems to program and coordinate manipulator movements.

- Performing troubleshooting, maintenance, and repairs on robotic manipulators to minimize downtime.

Frequently Asked Questions (FAQ’s) For Manipulator Operator

What are the key skills required to be a successful Manipulator Operator?

Key skills for a successful Manipulator Operator include proficiency in operating robotic manipulators, knowledge of programming and control systems, and expertise in troubleshooting and maintenance procedures. Additionally, strong analytical and problem-solving skills, attention to detail, and the ability to work independently and as part of a team are essential.

What industries typically employ Manipulator Operators?

Manipulator Operators find employment in various industries, including manufacturing, automotive, aerospace, pharmaceuticals, and research and development. They are responsible for operating robotic manipulators in automated production lines, performing delicate assembly tasks, handling hazardous materials, and assisting in scientific experiments.

What is the average salary range for Manipulator Operators?

The average salary range for Manipulator Operators varies depending on experience, industry, and location. According to Indeed, the average annual salary for a Manipulator Operator in the United States is around $60,000. However, salaries can range from $40,000 to $80,000 or more for experienced professionals.

What are the career advancement opportunities for Manipulator Operators?

Manipulator Operators can advance their careers by gaining experience and developing specialized skills. They can move into supervisory or management roles, become technical trainers, or pursue specialized certifications in robotics or automation. Additionally, they can explore opportunities in related fields such as robotics engineering or mechatronics.

What are some tips for writing a standout Manipulator Operator resume?

To write a standout Manipulator Operator resume, focus on highlighting your technical skills and experience in operating and maintaining robotic manipulators. Quantify your achievements whenever possible to demonstrate the impact of your contributions. Tailor your resume to each job you apply for, emphasizing the skills and experiences that are most relevant to the specific role. Additionally, proofread your resume carefully to ensure it is free of errors and presents a professional image.

What are the educational requirements for becoming a Manipulator Operator?

While there are no formal educational requirements to become a Manipulator Operator, most employers prefer candidates with a high school diploma or equivalent. Some employers may also require candidates to have an associate’s degree or certificate in a related field, such as automated manufacturing technology or engineering.

What are the physical demands of being a Manipulator Operator?

Manipulator Operators may need to stand for long periods, lift heavy objects, and work in awkward positions. They may also be exposed to noise, vibrations, and hazardous materials. It is important for Manipulator Operators to have good hand-eye coordination, dexterity, and physical stamina.

What are the safety precautions that Manipulator Operators must follow?

Manipulator Operators must follow strict safety precautions to prevent accidents and injuries. These precautions include wearing appropriate safety gear, such as gloves, safety glasses, and earplugs; being aware of their surroundings; and never putting their hands or other body parts near moving machinery. Manipulator Operators must also be trained in the proper operation and maintenance of robotic manipulators.