Are you a seasoned Plastic Process Technician seeking a new career path? Discover our professionally built Plastic Process Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

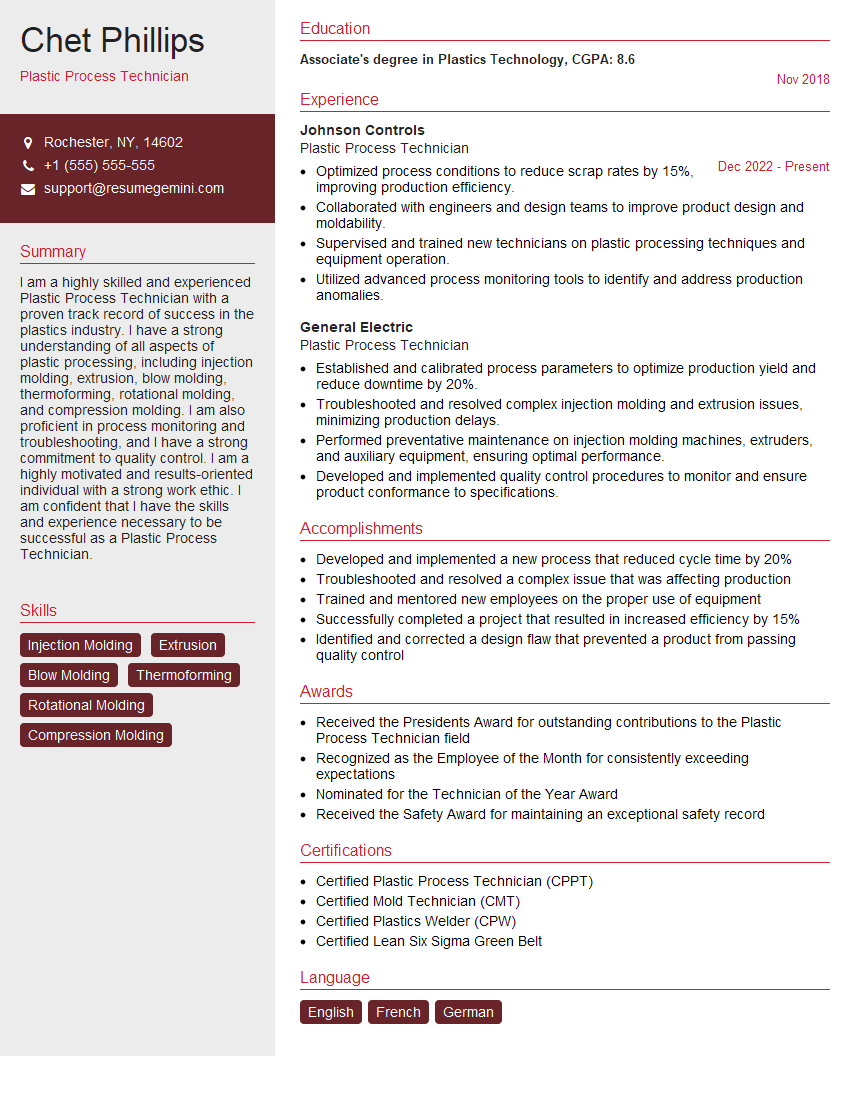

Chet Phillips

Plastic Process Technician

Summary

I am a highly skilled and experienced Plastic Process Technician with a proven track record of success in the plastics industry. I have a strong understanding of all aspects of plastic processing, including injection molding, extrusion, blow molding, thermoforming, rotational molding, and compression molding. I am also proficient in process monitoring and troubleshooting, and I have a strong commitment to quality control. I am a highly motivated and results-oriented individual with a strong work ethic. I am confident that I have the skills and experience necessary to be successful as a Plastic Process Technician.

Education

Associate’s degree in Plastics Technology

November 2018

Skills

- Injection Molding

- Extrusion

- Blow Molding

- Thermoforming

- Rotational Molding

- Compression Molding

Work Experience

Plastic Process Technician

- Optimized process conditions to reduce scrap rates by 15%, improving production efficiency.

- Collaborated with engineers and design teams to improve product design and moldability.

- Supervised and trained new technicians on plastic processing techniques and equipment operation.

- Utilized advanced process monitoring tools to identify and address production anomalies.

Plastic Process Technician

- Established and calibrated process parameters to optimize production yield and reduce downtime by 20%.

- Troubleshooted and resolved complex injection molding and extrusion issues, minimizing production delays.

- Performed preventative maintenance on injection molding machines, extruders, and auxiliary equipment, ensuring optimal performance.

- Developed and implemented quality control procedures to monitor and ensure product conformance to specifications.

Accomplishments

- Developed and implemented a new process that reduced cycle time by 20%

- Troubleshooted and resolved a complex issue that was affecting production

- Trained and mentored new employees on the proper use of equipment

- Successfully completed a project that resulted in increased efficiency by 15%

- Identified and corrected a design flaw that prevented a product from passing quality control

Awards

- Received the Presidents Award for outstanding contributions to the Plastic Process Technician field

- Recognized as the Employee of the Month for consistently exceeding expectations

- Nominated for the Technician of the Year Award

- Received the Safety Award for maintaining an exceptional safety record

Certificates

- Certified Plastic Process Technician (CPPT)

- Certified Mold Technician (CMT)

- Certified Plastics Welder (CPW)

- Certified Lean Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Process Technician

- Highlight your most relevant skills and experience in your resume.

- Use action verbs to describe your accomplishments.

- Quantify your results whenever possible.

- Proofread your resume carefully before submitting it.

- Network with other professionals in the plastics industry.

Essential Experience Highlights for a Strong Plastic Process Technician Resume

- Establish and calibrate process parameters to optimize production yield and reduce downtime.

- Troubleshoot and resolve complex injection molding and extrusion issues, minimizing production delays.

- Perform preventative maintenance on injection molding machines, extruders, and auxiliary equipment, ensuring optimal performance.

- Develop and implement quality control procedures to monitor and ensure product conformance to specifications.

- Optimize process conditions to reduce scrap rates, improving production efficiency.

- Collaborate with engineers and design teams to improve product design and moldability.

- Supervise and train new technicians on plastic processing techniques and equipment operation.

- Utilize advanced process monitoring tools to identify and address production anomalies.

Frequently Asked Questions (FAQ’s) For Plastic Process Technician

What are the different types of plastic processing techniques?

The most common types of plastic processing techniques are injection molding, extrusion, blow molding, thermoforming, rotational molding, and compression molding.

What are the essential skills for a Plastic Process Technician?

Essential skills for a Plastic Process Technician include a strong understanding of plastic processing techniques, process monitoring and troubleshooting, and quality control.

What is the job outlook for Plastic Process Technicians?

The job outlook for Plastic Process Technicians is expected to grow in the coming years due to the increasing demand for plastics in various industries.

What are the benefits of working as a Plastic Process Technician?

Benefits of working as a Plastic Process Technician include a competitive salary, job security, and the opportunity to work with cutting-edge technology.

What are the challenges of working as a Plastic Process Technician?

Challenges of working as a Plastic Process Technician include working in a fast-paced environment and dealing with hazardous materials.

What is the salary range for Plastic Process Technicians?

The salary range for Plastic Process Technicians varies depending on experience and location, but the average salary is around $35,000 per year.