Are you a seasoned Power Hammer Operator seeking a new career path? Discover our professionally built Power Hammer Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

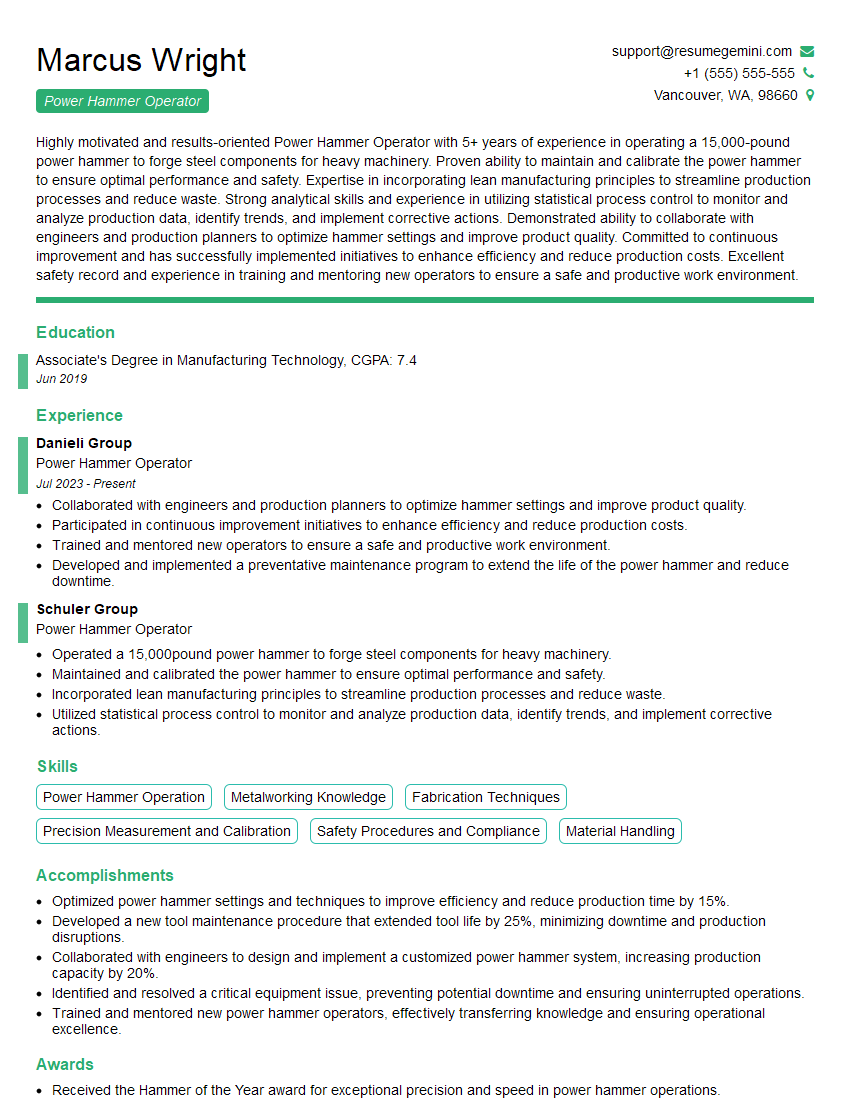

Marcus Wright

Power Hammer Operator

Summary

Highly motivated and results-oriented Power Hammer Operator with 5+ years of experience in operating a 15,000-pound power hammer to forge steel components for heavy machinery. Proven ability to maintain and calibrate the power hammer to ensure optimal performance and safety. Expertise in incorporating lean manufacturing principles to streamline production processes and reduce waste. Strong analytical skills and experience in utilizing statistical process control to monitor and analyze production data, identify trends, and implement corrective actions. Demonstrated ability to collaborate with engineers and production planners to optimize hammer settings and improve product quality. Committed to continuous improvement and has successfully implemented initiatives to enhance efficiency and reduce production costs. Excellent safety record and experience in training and mentoring new operators to ensure a safe and productive work environment.

Education

Associate’s Degree in Manufacturing Technology

June 2019

Skills

- Power Hammer Operation

- Metalworking Knowledge

- Fabrication Techniques

- Precision Measurement and Calibration

- Safety Procedures and Compliance

- Material Handling

Work Experience

Power Hammer Operator

- Collaborated with engineers and production planners to optimize hammer settings and improve product quality.

- Participated in continuous improvement initiatives to enhance efficiency and reduce production costs.

- Trained and mentored new operators to ensure a safe and productive work environment.

- Developed and implemented a preventative maintenance program to extend the life of the power hammer and reduce downtime.

Power Hammer Operator

- Operated a 15,000pound power hammer to forge steel components for heavy machinery.

- Maintained and calibrated the power hammer to ensure optimal performance and safety.

- Incorporated lean manufacturing principles to streamline production processes and reduce waste.

- Utilized statistical process control to monitor and analyze production data, identify trends, and implement corrective actions.

Accomplishments

- Optimized power hammer settings and techniques to improve efficiency and reduce production time by 15%.

- Developed a new tool maintenance procedure that extended tool life by 25%, minimizing downtime and production disruptions.

- Collaborated with engineers to design and implement a customized power hammer system, increasing production capacity by 20%.

- Identified and resolved a critical equipment issue, preventing potential downtime and ensuring uninterrupted operations.

- Trained and mentored new power hammer operators, effectively transferring knowledge and ensuring operational excellence.

Awards

- Received the Hammer of the Year award for exceptional precision and speed in power hammer operations.

- Recognized with the Safety Excellence Award for maintaining an impeccable safety record and implementing innovative safety measures.

- Honored with the Production Champion Award for consistently exceeding production targets and reducing waste.

- Recipient of the Quality Management Award for exceptional attention to quality and adherence to industry standards.

Certificates

- Certified Power Hammer Operator

- Certified Metalworking Technician

- OSHA 10-Hour General Industry Safety Certification

- Certified Forklift Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Power Hammer Operator

- Highlight your experience in operating a power hammer and the specific types of components you have forged.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on productivity, quality, and cost reduction.

- Emphasize your knowledge of metalworking techniques, fabrication methods, and precision measurement and calibration.

- Showcase your commitment to safety and compliance by describing your experience with safety procedures and regulations.

- Highlight your ability to work independently and as part of a team, and your willingness to learn and adapt to new technologies and processes.

Essential Experience Highlights for a Strong Power Hammer Operator Resume

- Operated a 15,000-pound power hammer to forge steel components for heavy machinery.

- Maintained and calibrated the power hammer to ensure optimal performance and safety.

- Incorporated lean manufacturing principles to streamline production processes and reduce waste.

- Utilized statistical process control to monitor and analyze production data, identify trends, and implement corrective actions.

- Collaborated with engineers and production planners to optimize hammer settings and improve product quality.

- Participated in continuous improvement initiatives to enhance efficiency and reduce production costs.

- Trained and mentored new operators to ensure a safe and productive work environment.

- Developed and implemented a preventative maintenance program to extend the life of the power hammer and reduce downtime.

Frequently Asked Questions (FAQ’s) For Power Hammer Operator

What is the role of a Power Hammer Operator?

A Power Hammer Operator is responsible for operating a power hammer to forge steel components for heavy machinery. They maintain and calibrate the power hammer to ensure optimal performance and safety, and incorporate lean manufacturing principles to streamline production processes and reduce waste.

What skills are required to be a successful Power Hammer Operator?

Successful Power Hammer Operators have experience in operating a power hammer, knowledge of metalworking techniques, and expertise in precision measurement and calibration. They are also familiar with safety procedures and compliance regulations, and are able to work independently and as part of a team.

What are the career prospects for Power Hammer Operators?

Power Hammer Operators can advance to positions such as Production Supervisor, Manufacturing Manager, or Quality Control Inspector. With additional education and experience, they may also qualify for engineering or management roles in the manufacturing industry.

What is the average salary for a Power Hammer Operator?

The average salary for a Power Hammer Operator in the United States is around $45,000 per year. However, salaries may vary depending on experience, location, and industry.

What are the working conditions for Power Hammer Operators?

Power Hammer Operators typically work in manufacturing facilities, where they may be exposed to noise, dust, and heat. They may also work with heavy machinery and hazardous materials, so it is important to follow safety procedures and wear appropriate protective gear.

What is the job outlook for Power Hammer Operators?

The job outlook for Power Hammer Operators is expected to be good in the coming years, as there will continue to be a demand for skilled workers in the manufacturing industry. However, automation and technological advancements may impact the demand for some positions.

How can I become a Power Hammer Operator?

To become a Power Hammer Operator, you can complete an associate’s degree in manufacturing technology or a related field, and gain experience in operating a power hammer. You can also complete an apprenticeship program or on-the-job training to acquire the necessary skills and knowledge.