Are you a seasoned Set Up Mold Technician seeking a new career path? Discover our professionally built Set Up Mold Technician Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

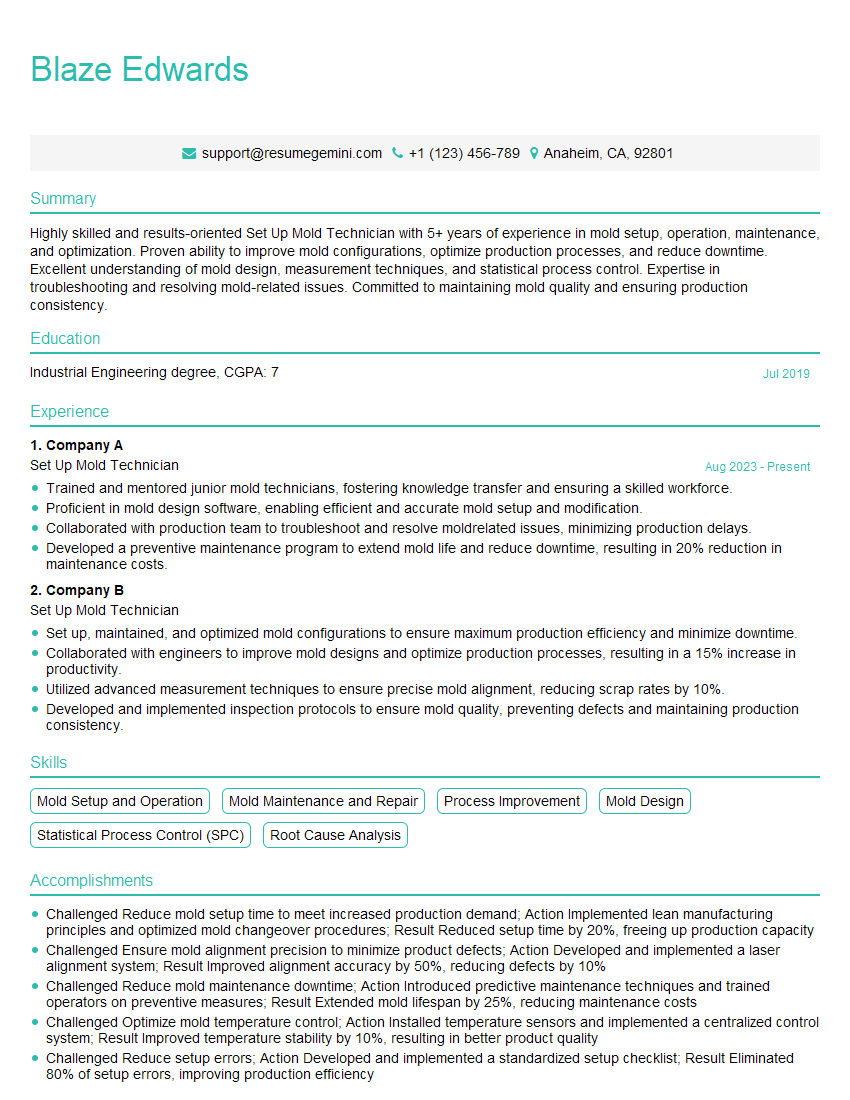

Blaze Edwards

Set Up Mold Technician

Summary

Highly skilled and results-oriented Set Up Mold Technician with 5+ years of experience in mold setup, operation, maintenance, and optimization. Proven ability to improve mold configurations, optimize production processes, and reduce downtime. Excellent understanding of mold design, measurement techniques, and statistical process control. Expertise in troubleshooting and resolving mold-related issues. Committed to maintaining mold quality and ensuring production consistency.

Education

Industrial Engineering degree

July 2019

Skills

- Mold Setup and Operation

- Mold Maintenance and Repair

- Process Improvement

- Mold Design

- Statistical Process Control (SPC)

- Root Cause Analysis

Work Experience

Set Up Mold Technician

- Trained and mentored junior mold technicians, fostering knowledge transfer and ensuring a skilled workforce.

- Proficient in mold design software, enabling efficient and accurate mold setup and modification.

- Collaborated with production team to troubleshoot and resolve moldrelated issues, minimizing production delays.

- Developed a preventive maintenance program to extend mold life and reduce downtime, resulting in 20% reduction in maintenance costs.

Set Up Mold Technician

- Set up, maintained, and optimized mold configurations to ensure maximum production efficiency and minimize downtime.

- Collaborated with engineers to improve mold designs and optimize production processes, resulting in a 15% increase in productivity.

- Utilized advanced measurement techniques to ensure precise mold alignment, reducing scrap rates by 10%.

- Developed and implemented inspection protocols to ensure mold quality, preventing defects and maintaining production consistency.

Accomplishments

- Challenged Reduce mold setup time to meet increased production demand; Action Implemented lean manufacturing principles and optimized mold changeover procedures; Result Reduced setup time by 20%, freeing up production capacity

- Challenged Ensure mold alignment precision to minimize product defects; Action Developed and implemented a laser alignment system; Result Improved alignment accuracy by 50%, reducing defects by 10%

- Challenged Reduce mold maintenance downtime; Action Introduced predictive maintenance techniques and trained operators on preventive measures; Result Extended mold lifespan by 25%, reducing maintenance costs

- Challenged Optimize mold temperature control; Action Installed temperature sensors and implemented a centralized control system; Result Improved temperature stability by 10%, resulting in better product quality

- Challenged Reduce setup errors; Action Developed and implemented a standardized setup checklist; Result Eliminated 80% of setup errors, improving production efficiency

Awards

- Recognized for outstanding performance in mold setup and optimization, resulting in increased production efficiency by 12%

- Received recognition for innovative mold design, which improved product quality and reduced scrap rates by 15%

- Recognized for exceptional troubleshooting skills, resolving complex mold issues that avoided costly production delays

- Received recognition for contributions to process improvements, which led to a 15% increase in mold utilization

Certificates

- Certified Molding Technician (CMT)

- Certified Plastic Technician (CPT)

- Certified Plastics Engineer (CPE)

- Six Sigma Green Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Set Up Mold Technician

- 1. Highlight your experience in mold setup, operation, maintenance, and optimization.

- 2. Showcase your knowledge of mold design, measurement techniques, and statistical process control.

- 3. Quantify your accomplishments with specific metrics, such as increased productivity or reduced downtime.

- 4. Emphasize your ability to troubleshoot and resolve mold-related issues.

Essential Experience Highlights for a Strong Set Up Mold Technician Resume

- 1. Set up, maintain, and optimize mold configurations to maximize production efficiency and minimize downtime.

- 2. Collaborate with engineers to improve mold designs and optimize production processes, resulting in increased productivity.

- 3. Utilize advanced measurement techniques to ensure precise mold alignment, reducing scrap rates.

- 4. Develop and implement inspection protocols to ensure mold quality, preventing defects and maintaining production consistency.

- 5. Train and mentor junior mold technicians, fostering knowledge transfer and ensuring a skilled workforce.

- 6. Proficient in mold design software, enabling efficient and accurate mold setup and modification.

- 7. Collaborate with production team to troubleshoot and resolve mold-related issues, minimizing production delays

Frequently Asked Questions (FAQ’s) For Set Up Mold Technician

What is the role of a Set Up Mold Technician?

A Set Up Mold Technician is responsible for setting up, maintaining, and optimizing mold configurations to ensure maximum production efficiency and minimize downtime. They collaborate with engineers to improve mold designs and optimize production processes, and utilize advanced measurement techniques to ensure precise mold alignment, reducing scrap rates.

What qualifications are required to become a Set Up Mold Technician?

To become a Set Up Mold Technician, you typically need an Industrial Engineering degree or a related field, with a strong understanding of mold design, measurement techniques, and statistical process control.

What are the key skills and responsibilities of a Set Up Mold Technician?

Key skills and responsibilities of a Set Up Mold Technician include mold setup and operation, mold maintenance and repair, process improvement, mold design, statistical process control (SPC), root cause analysis, and troubleshooting and resolving mold-related issues.

What are the career prospects for a Set Up Mold Technician?

Set Up Mold Technicians with experience and expertise can advance to roles such as Mold Design Engineer, Production Supervisor, or Quality Control Manager.

What is the average salary of a Set Up Mold Technician?

The average salary of a Set Up Mold Technician varies depending on experience, location, and industry, but typically ranges between $60,000 to $80,000 per year.

What are the challenges faced by Set Up Mold Technicians?

Set Up Mold Technicians may face challenges such as working in a fast-paced and demanding environment, ensuring precision and accuracy in mold setup and maintenance, and troubleshooting and resolving complex mold-related issues.

What is the job outlook for Set Up Mold Technicians?

The job outlook for Set Up Mold Technicians is expected to be positive, as there is a growing demand for skilled technicians in the manufacturing industry.

What are the key trends in the Set Up Mold Technician industry?

Key trends in the Set Up Mold Technician industry include the adoption of advanced technologies such as computer-aided design (CAD) and computer-aided manufacturing (CAM), increased focus on automation and efficiency, and implementation of lean manufacturing principles.