Are you a seasoned Brass Roller seeking a new career path? Discover our professionally built Brass Roller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

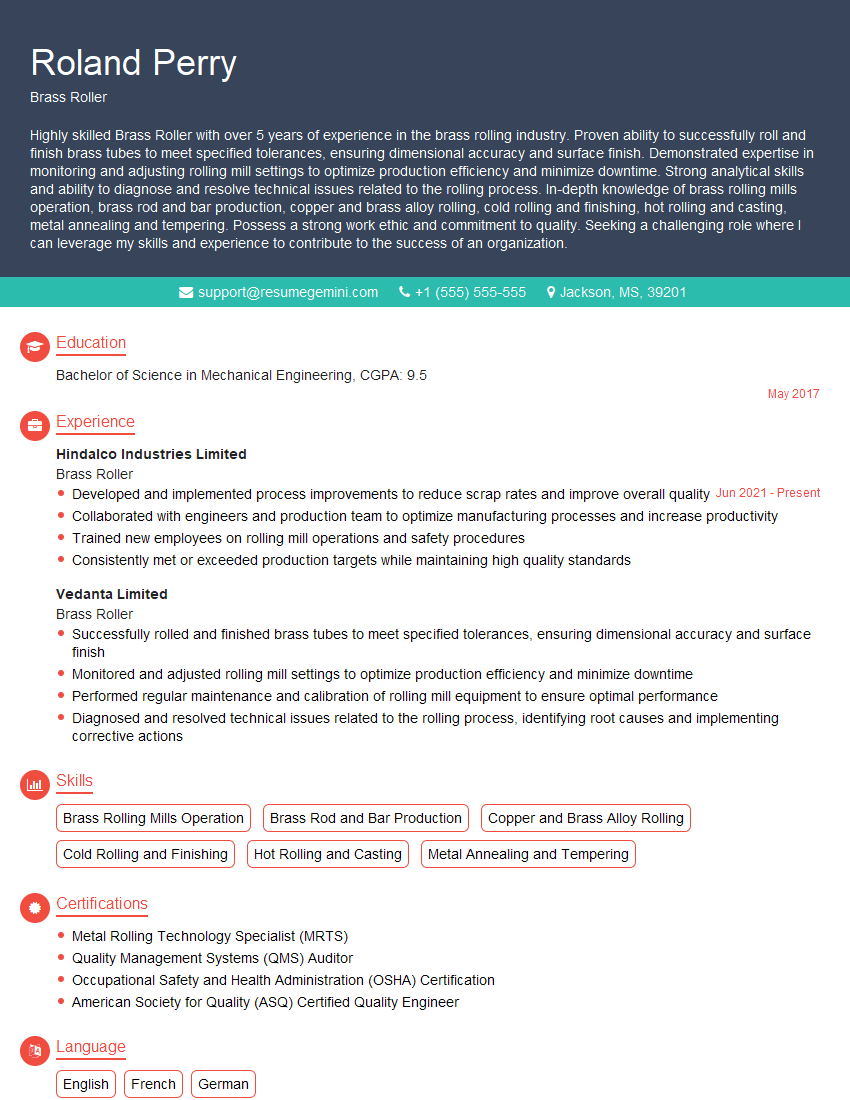

Roland Perry

Brass Roller

Summary

Highly skilled Brass Roller with over 5 years of experience in the brass rolling industry. Proven ability to successfully roll and finish brass tubes to meet specified tolerances, ensuring dimensional accuracy and surface finish. Demonstrated expertise in monitoring and adjusting rolling mill settings to optimize production efficiency and minimize downtime. Strong analytical skills and ability to diagnose and resolve technical issues related to the rolling process. In-depth knowledge of brass rolling mills operation, brass rod and bar production, copper and brass alloy rolling, cold rolling and finishing, hot rolling and casting, metal annealing and tempering. Possess a strong work ethic and commitment to quality. Seeking a challenging role where I can leverage my skills and experience to contribute to the success of an organization.

Education

Bachelor of Science in Mechanical Engineering

May 2017

Skills

- Brass Rolling Mills Operation

- Brass Rod and Bar Production

- Copper and Brass Alloy Rolling

- Cold Rolling and Finishing

- Hot Rolling and Casting

- Metal Annealing and Tempering

Work Experience

Brass Roller

- Developed and implemented process improvements to reduce scrap rates and improve overall quality

- Collaborated with engineers and production team to optimize manufacturing processes and increase productivity

- Trained new employees on rolling mill operations and safety procedures

- Consistently met or exceeded production targets while maintaining high quality standards

Brass Roller

- Successfully rolled and finished brass tubes to meet specified tolerances, ensuring dimensional accuracy and surface finish

- Monitored and adjusted rolling mill settings to optimize production efficiency and minimize downtime

- Performed regular maintenance and calibration of rolling mill equipment to ensure optimal performance

- Diagnosed and resolved technical issues related to the rolling process, identifying root causes and implementing corrective actions

Certificates

- Metal Rolling Technology Specialist (MRTS)

- Quality Management Systems (QMS) Auditor

- Occupational Safety and Health Administration (OSHA) Certification

- American Society for Quality (ASQ) Certified Quality Engineer

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Brass Roller

- Highlight your experience and skills in brass rolling, including specific examples of your accomplishments.

- Demonstrate your knowledge of brass rolling mills operation, brass rod and bar production, copper and brass alloy rolling, cold rolling and finishing, hot rolling and casting, metal annealing and tempering.

- Emphasize your ability to diagnose and resolve technical issues related to the rolling process.

- Showcase your commitment to quality and your ability to work effectively in a team environment.

- Proofread your resume carefully for any errors in grammar or spelling.

Essential Experience Highlights for a Strong Brass Roller Resume

- Rolled and finished brass tubes to meet specified tolerances, ensuring dimensional accuracy and surface finish.

- Monitored and adjusted rolling mill settings to optimize production efficiency and minimize downtime.

- Performed regular maintenance and calibration of rolling mill equipment to ensure optimal performance.

- Diagnosed and resolved technical issues related to the rolling process, identifying root causes and implementing corrective actions.

- Developed and implemented process improvements to reduce scrap rates and improve overall quality.

- Collaborated with engineers and production team to optimize manufacturing processes and increase productivity.

- Trained new employees on rolling mill operations and safety procedures.

Frequently Asked Questions (FAQ’s) For Brass Roller

What is the role of a Brass Roller?

A Brass Roller is responsible for rolling and finishing brass tubes to meet specified tolerances, ensuring dimensional accuracy and surface finish. They also monitor and adjust rolling mill settings to optimize production efficiency and minimize downtime, perform regular maintenance and calibration of rolling mill equipment to ensure optimal performance, diagnose and resolve technical issues related to the rolling process, develop and implement process improvements to reduce scrap rates and improve overall quality, collaborate with engineers and production team to optimize manufacturing processes and increase productivity, train new employees on rolling mill operations and safety procedures.

What skills are required to be a successful Brass Roller?

To be a successful Brass Roller, you need to have experience in brass rolling, including specific examples of your accomplishments. You should also have knowledge of brass rolling mills operation, brass rod and bar production, copper and brass alloy rolling, cold rolling and finishing, hot rolling and casting, metal annealing and tempering. Additionally, you should be able to diagnose and resolve technical issues related to the rolling process, and be committed to quality and able to work effectively in a team environment.

What is the career path for a Brass Roller?

The career path for a Brass Roller can vary depending on your experience and qualifications. With experience, you may be able to move into a supervisory or management role, or you may be able to specialize in a particular area of brass rolling. Additionally, you may be able to start your own business.

What is the job outlook for Brass Rollers?

The job outlook for Brass Rollers is expected to be good over the next few years. This is due to the increasing demand for brass products, such as tubes, rods, and bars. Additionally, the growing use of brass in industries such as construction and automotive is also expected to contribute to the positive job outlook for Brass Rollers.

What are the benefits of working as a Brass Roller?

There are many benefits to working as a Brass Roller, including the opportunity to work with a variety of materials, the chance to learn about the brass rolling process, and the opportunity to develop your skills and knowledge. Additionally, Brass Rollers can earn a competitive salary and benefits package.

What are the challenges of working as a Brass Roller?

There are some challenges to working as a Brass Roller, including the physical demands of the job, the potential for exposure to hazardous materials, and the need to work in a hot and noisy environment. Additionally, Brass Rollers may need to work overtime or on weekends to meet production demands.

What is the average salary for a Brass Roller?

The average salary for a Brass Roller can vary depending on your experience, qualifications, and location. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Metal Workers and Plastic Workers was $49,520 in May 2021.

What are the educational requirements for a Brass Roller?

The educational requirements for a Brass Roller can vary depending on the specific job requirements. However, most Brass Rollers have a high school diploma or equivalent. Some Brass Rollers may also have a college degree in a related field, such as mechanical engineering or materials science.