Are you a seasoned Steel Roller seeking a new career path? Discover our professionally built Steel Roller Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

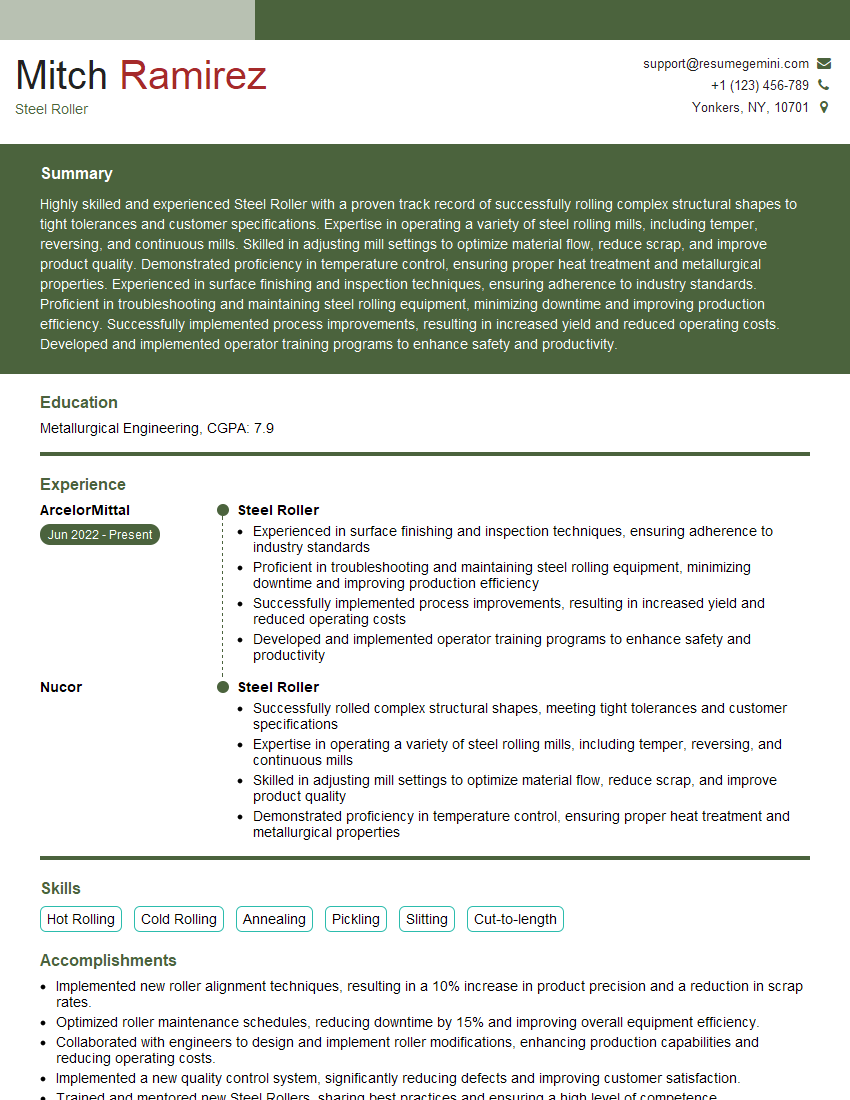

Mitch Ramirez

Steel Roller

Summary

Highly skilled and experienced Steel Roller with a proven track record of successfully rolling complex structural shapes to tight tolerances and customer specifications. Expertise in operating a variety of steel rolling mills, including temper, reversing, and continuous mills. Skilled in adjusting mill settings to optimize material flow, reduce scrap, and improve product quality. Demonstrated proficiency in temperature control, ensuring proper heat treatment and metallurgical properties. Experienced in surface finishing and inspection techniques, ensuring adherence to industry standards. Proficient in troubleshooting and maintaining steel rolling equipment, minimizing downtime and improving production efficiency. Successfully implemented process improvements, resulting in increased yield and reduced operating costs. Developed and implemented operator training programs to enhance safety and productivity.

Education

Metallurgical Engineering

May 2018

Skills

- Hot Rolling

- Cold Rolling

- Annealing

- Pickling

- Slitting

- Cut-to-length

Work Experience

Steel Roller

- Experienced in surface finishing and inspection techniques, ensuring adherence to industry standards

- Proficient in troubleshooting and maintaining steel rolling equipment, minimizing downtime and improving production efficiency

- Successfully implemented process improvements, resulting in increased yield and reduced operating costs

- Developed and implemented operator training programs to enhance safety and productivity

Steel Roller

- Successfully rolled complex structural shapes, meeting tight tolerances and customer specifications

- Expertise in operating a variety of steel rolling mills, including temper, reversing, and continuous mills

- Skilled in adjusting mill settings to optimize material flow, reduce scrap, and improve product quality

- Demonstrated proficiency in temperature control, ensuring proper heat treatment and metallurgical properties

Accomplishments

- Implemented new roller alignment techniques, resulting in a 10% increase in product precision and a reduction in scrap rates.

- Optimized roller maintenance schedules, reducing downtime by 15% and improving overall equipment efficiency.

- Collaborated with engineers to design and implement roller modifications, enhancing production capabilities and reducing operating costs.

- Implemented a new quality control system, significantly reducing defects and improving customer satisfaction.

- Trained and mentored new Steel Rollers, sharing best practices and ensuring a high level of competence.

Awards

- Received Steel Roller Operator of the Year Award for consistently exceeding production targets and maintaining exceptional quality standards.

- Recognized for outstanding safety record, maintaining a spotless safety record for over 5 years.

- Received recognition for innovation in developing a new roller calibration method, reducing setup times by 20%.

- Honored for commitment to continuous improvement, actively pursuing training and certifications to enhance skills.

Certificates

- Certified Hot Mill Operator

- Certified Cold Mill Operator

- Certified Annealing Operator

- Certified Pickling Operator

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steel Roller

- Highlight your experience in operating a variety of steel rolling mills, including temper, reversing, and continuous mills.

- Showcase your skills in adjusting mill settings to optimize material flow, reduce scrap, and improve product quality.

- Emphasize your proficiency in temperature control, ensuring proper heat treatment and metallurgical properties.

- Demonstrate your experience in surface finishing and inspection techniques, ensuring adherence to industry standards.

- Highlight your troubleshooting and maintenance skills, as well as your ability to implement process improvements and develop operator training programs.

Essential Experience Highlights for a Strong Steel Roller Resume

- Operate a variety of steel rolling mills, including temper, reversing, and continuous mills, to produce structural shapes to meet customer specifications

- Adjust mill settings to optimize material flow, reduce scrap, and improve product quality

- Monitor and control temperature to ensure proper heat treatment and metallurgical properties

- Perform surface finishing and inspection techniques to ensure adherence to industry standards

- Troubleshoot and maintain steel rolling equipment to minimize downtime and improve production efficiency

- Implement process improvements to increase yield and reduce operating costs

- Develop and implement operator training programs to enhance safety and productivity

Frequently Asked Questions (FAQ’s) For Steel Roller

What is the role of a Steel Roller?

Steel Rollers operate steel rolling mills to produce structural shapes to meet customer specifications. They adjust mill settings, monitor temperature, perform surface finishing and inspection techniques, troubleshoot and maintain equipment, implement process improvements, and develop operator training programs.

What are the qualifications to become a Steel Roller?

Steel Rollers typically need a high school diploma or equivalent and on-the-job training. Some employers may prefer candidates with a degree in metallurgical engineering or a related field.

What skills are required to be a Steel Roller?

Steel Rollers need to have mechanical aptitude, attention to detail, and the ability to work in a team environment. They should also be able to operate a variety of steel rolling mills, adjust mill settings, monitor temperature, perform surface finishing and inspection techniques, troubleshoot and maintain equipment, and implement process improvements.

What is the career outlook for Steel Rollers?

The career outlook for Steel Rollers is expected to be good over the next few years. The demand for steel is expected to grow, which will lead to an increased demand for Steel Rollers.

What is the average salary for a Steel Roller?

The average salary for a Steel Roller is around $60,000 per year.

What are the benefits of being a Steel Roller?

Steel Rollers enjoy a variety of benefits, including a competitive salary, health insurance, paid time off, and retirement benefits.

What are the challenges of being a Steel Roller?

Steel Rollers face a number of challenges, including working in a hot and noisy environment, exposure to hazardous chemicals, and the need to work long hours.