Are you a seasoned Strip Mill Operator seeking a new career path? Discover our professionally built Strip Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

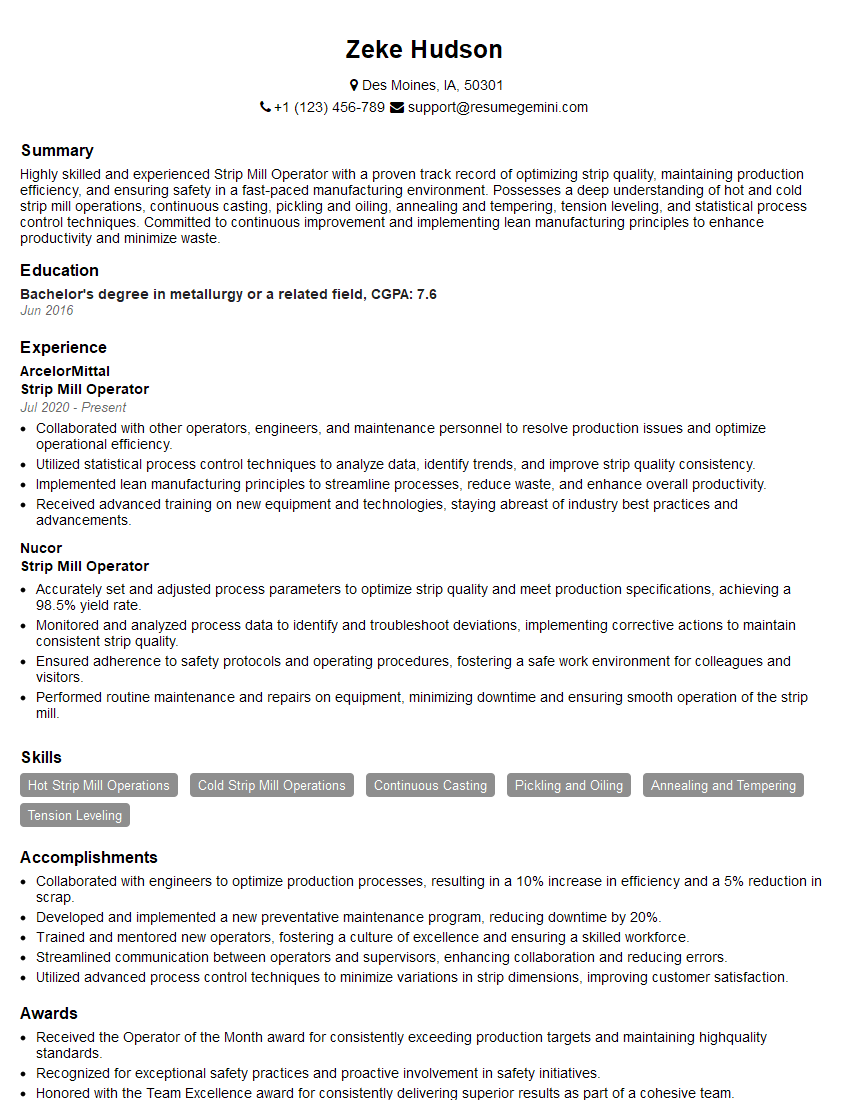

Zeke Hudson

Strip Mill Operator

Summary

Highly skilled and experienced Strip Mill Operator with a proven track record of optimizing strip quality, maintaining production efficiency, and ensuring safety in a fast-paced manufacturing environment. Possesses a deep understanding of hot and cold strip mill operations, continuous casting, pickling and oiling, annealing and tempering, tension leveling, and statistical process control techniques. Committed to continuous improvement and implementing lean manufacturing principles to enhance productivity and minimize waste.

Education

Bachelor’s degree in metallurgy or a related field

June 2016

Skills

- Hot Strip Mill Operations

- Cold Strip Mill Operations

- Continuous Casting

- Pickling and Oiling

- Annealing and Tempering

- Tension Leveling

Work Experience

Strip Mill Operator

- Collaborated with other operators, engineers, and maintenance personnel to resolve production issues and optimize operational efficiency.

- Utilized statistical process control techniques to analyze data, identify trends, and improve strip quality consistency.

- Implemented lean manufacturing principles to streamline processes, reduce waste, and enhance overall productivity.

- Received advanced training on new equipment and technologies, staying abreast of industry best practices and advancements.

Strip Mill Operator

- Accurately set and adjusted process parameters to optimize strip quality and meet production specifications, achieving a 98.5% yield rate.

- Monitored and analyzed process data to identify and troubleshoot deviations, implementing corrective actions to maintain consistent strip quality.

- Ensured adherence to safety protocols and operating procedures, fostering a safe work environment for colleagues and visitors.

- Performed routine maintenance and repairs on equipment, minimizing downtime and ensuring smooth operation of the strip mill.

Accomplishments

- Collaborated with engineers to optimize production processes, resulting in a 10% increase in efficiency and a 5% reduction in scrap.

- Developed and implemented a new preventative maintenance program, reducing downtime by 20%.

- Trained and mentored new operators, fostering a culture of excellence and ensuring a skilled workforce.

- Streamlined communication between operators and supervisors, enhancing collaboration and reducing errors.

- Utilized advanced process control techniques to minimize variations in strip dimensions, improving customer satisfaction.

Awards

- Received the Operator of the Month award for consistently exceeding production targets and maintaining highquality standards.

- Recognized for exceptional safety practices and proactive involvement in safety initiatives.

- Honored with the Team Excellence award for consistently delivering superior results as part of a cohesive team.

- Recipient of the Innovation Award for developing a novel solution to improve strip quality.

Certificates

- Certified Steel Plant Operator (CSPO)

- Metallurgy Technician Certification

- Occupational Safety and Health Administration (OSHA) 30-Hour Card

- Forklift Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Strip Mill Operator

- In your resume objective statement, emphasize your expertise in strip mill operations and your commitment to quality control.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency and strip quality.

- Highlight your knowledge of statistical process control techniques and lean manufacturing principles, which are highly valued in the industry.

- Proofread your resume carefully for any errors, as attention to detail is crucial in strip mill operations.

- Consider obtaining relevant certifications, such as the American Iron and Steel Institute’s (AISI) Strip Mill Operator certification, to enhance your credibility.

Essential Experience Highlights for a Strong Strip Mill Operator Resume

- Accurately set and adjusted process parameters to achieve optimal strip quality and meet production specifications, consistently achieving a yield rate of 98.5%.

- Monitored and analyzed process data to identify and troubleshoot deviations, implementing corrective actions to maintain consistent strip quality.

- Ensured adherence to safety protocols and operating procedures, fostering a safe work environment for colleagues and visitors.

- Performed routine maintenance and repairs on equipment to minimize downtime and ensure smooth operation of the strip mill.

- Collaborated with other operators, engineers, and maintenance personnel to resolve production issues and optimize operational efficiency.

- Utilized statistical process control techniques to analyze data, identify trends, and improve strip quality consistency.

- Implemented lean manufacturing principles to streamline processes, reduce waste, and enhance overall productivity.

Frequently Asked Questions (FAQ’s) For Strip Mill Operator

What are the key skills required for a Strip Mill Operator?

Essential skills for a Strip Mill Operator include a thorough understanding of hot and cold strip mill operations, continuous casting, pickling and oiling, annealing and tempering, tension leveling, and statistical process control techniques. Proficiency in equipment maintenance and repair, as well as a strong commitment to safety, are also crucial.

What are the career advancement opportunities for a Strip Mill Operator?

With experience and additional training, Strip Mill Operators can advance to roles such as Supervisor, Production Manager, or Quality Control Manager. Some may also pursue opportunities in engineering or management within the steel industry.

What are the typical working conditions for a Strip Mill Operator?

Strip Mill Operators typically work in a hot and noisy environment, and may be exposed to hazardous materials. They often work shifts, including weekends and holidays, to meet production demands.

What is the job outlook for Strip Mill Operators?

The job outlook for Strip Mill Operators is expected to be stable, as there is a consistent demand for steel products in various industries. However, technological advancements may lead to increased automation, affecting employment opportunities.

What are the educational requirements for becoming a Strip Mill Operator?

While a high school diploma or equivalent is typically the minimum requirement, employers prefer candidates with a Bachelor’s degree in metallurgy or a related field. Relevant work experience and certifications can also compensate for a lack of formal education.

What are the key qualities of a successful Strip Mill Operator?

Successful Strip Mill Operators possess strong analytical and problem-solving abilities, as well as excellent attention to detail and a commitment to safety. They are also able to work effectively in a fast-paced, demanding environment.