Are you a seasoned Tandem Mill Operator seeking a new career path? Discover our professionally built Tandem Mill Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

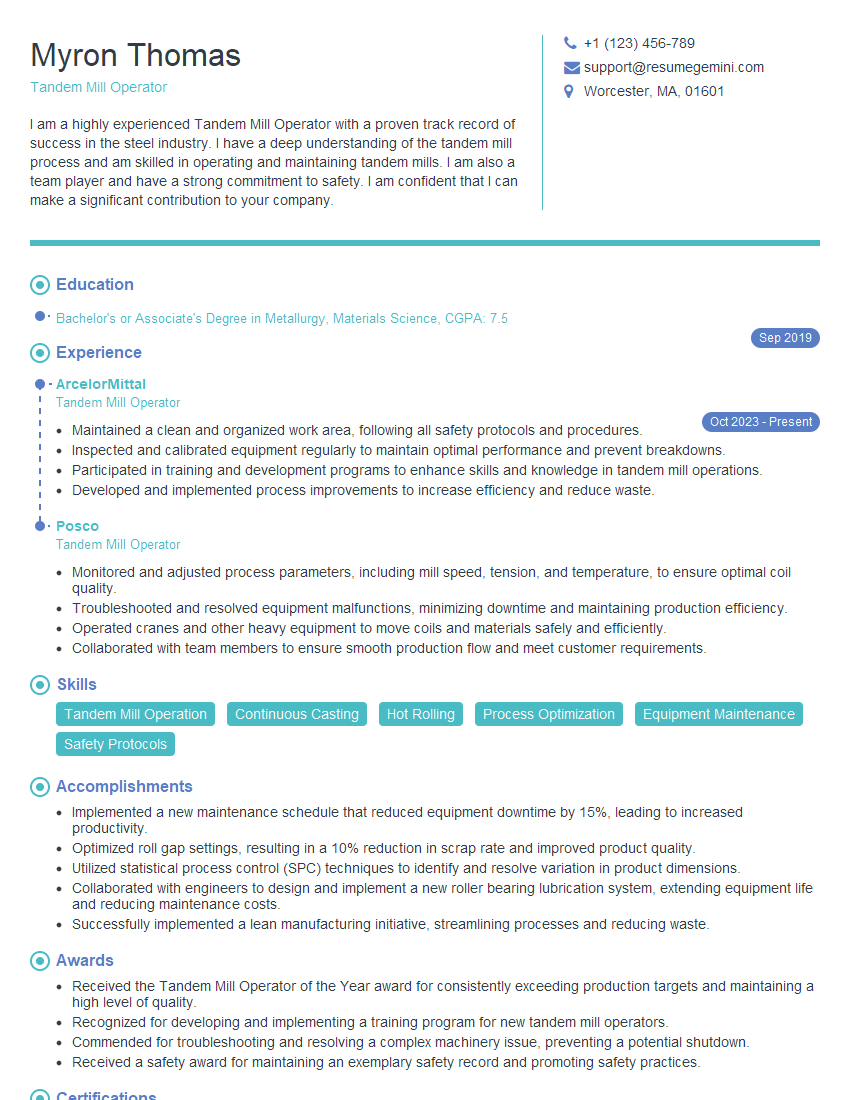

Myron Thomas

Tandem Mill Operator

Summary

I am a highly experienced Tandem Mill Operator with a proven track record of success in the steel industry. I have a deep understanding of the tandem mill process and am skilled in operating and maintaining tandem mills. I am also a team player and have a strong commitment to safety. I am confident that I can make a significant contribution to your company.

Education

Bachelor’s or Associate’s Degree in Metallurgy, Materials Science

September 2019

Skills

- Tandem Mill Operation

- Continuous Casting

- Hot Rolling

- Process Optimization

- Equipment Maintenance

- Safety Protocols

Work Experience

Tandem Mill Operator

- Maintained a clean and organized work area, following all safety protocols and procedures.

- Inspected and calibrated equipment regularly to maintain optimal performance and prevent breakdowns.

- Participated in training and development programs to enhance skills and knowledge in tandem mill operations.

- Developed and implemented process improvements to increase efficiency and reduce waste.

Tandem Mill Operator

- Monitored and adjusted process parameters, including mill speed, tension, and temperature, to ensure optimal coil quality.

- Troubleshooted and resolved equipment malfunctions, minimizing downtime and maintaining production efficiency.

- Operated cranes and other heavy equipment to move coils and materials safely and efficiently.

- Collaborated with team members to ensure smooth production flow and meet customer requirements.

Accomplishments

- Implemented a new maintenance schedule that reduced equipment downtime by 15%, leading to increased productivity.

- Optimized roll gap settings, resulting in a 10% reduction in scrap rate and improved product quality.

- Utilized statistical process control (SPC) techniques to identify and resolve variation in product dimensions.

- Collaborated with engineers to design and implement a new roller bearing lubrication system, extending equipment life and reducing maintenance costs.

- Successfully implemented a lean manufacturing initiative, streamlining processes and reducing waste.

Awards

- Received the Tandem Mill Operator of the Year award for consistently exceeding production targets and maintaining a high level of quality.

- Recognized for developing and implementing a training program for new tandem mill operators.

- Commended for troubleshooting and resolving a complex machinery issue, preventing a potential shutdown.

- Received a safety award for maintaining an exemplary safety record and promoting safety practices.

Certificates

- Tandem Mill Operator Certification

- Hot Rolling Certification

- Process Optimization Certification

- Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Tandem Mill Operator

- Highlight your experience in operating and maintaining tandem mills.

- Demonstrate your knowledge of the tandem mill process.

- Quantify your accomplishments whenever possible.

- Use keywords from the job description in your resume.

- Proofread your resume carefully before sending it to potential employers.

Essential Experience Highlights for a Strong Tandem Mill Operator Resume

- Monitoring and adjusting process parameters, including mill speed, tension, and temperature, to ensure optimal coil quality.

- Troubleshooting and resolving equipment malfunctions, minimizing downtime and maintaining production efficiency.

- Operating cranes and other heavy equipment to move coils and materials safely and efficiently.

- Collaborating with team members to ensure smooth production flow and meet customer requirements.

- Maintaining a clean and organized work area, following all safety protocols and procedures.

- Inspecting and calibrating equipment regularly to maintain optimal performance and prevent breakdowns.

- Participating in training and development programs to enhance skills and knowledge in tandem mill operations.

Frequently Asked Questions (FAQ’s) For Tandem Mill Operator

What is a Tandem Mill Operator?

A Tandem Mill Operator is responsible for operating and maintaining a tandem mill, which is a machine used to roll metal into thin sheets.

What are the qualifications for a Tandem Mill Operator?

Most Tandem Mill Operators have a high school diploma or equivalent, and some may have a college degree in a related field, such as metallurgy or engineering.

What are the responsibilities of a Tandem Mill Operator?

Tandem Mill Operators are responsible for a variety of tasks, including monitoring and adjusting process parameters, troubleshooting and resolving equipment malfunctions, operating cranes and other heavy equipment, and maintaining a clean and organized work area.

What are the benefits of working as a Tandem Mill Operator?

Tandem Mill Operators can enjoy a variety of benefits, including competitive pay, health insurance, and retirement benefits.

What are the challenges of working as a Tandem Mill Operator?

Tandem Mill Operators can face a variety of challenges, including working in a hot and noisy environment, working with heavy equipment, and working long hours.

What is the career outlook for Tandem Mill Operators?

The career outlook for Tandem Mill Operators is expected to be good over the next few years.

How can I become a Tandem Mill Operator?

To become a Tandem Mill Operator, you will need to have a high school diploma or equivalent, and some experience working in a manufacturing environment.