Are you a seasoned Clearance Cutter seeking a new career path? Discover our professionally built Clearance Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

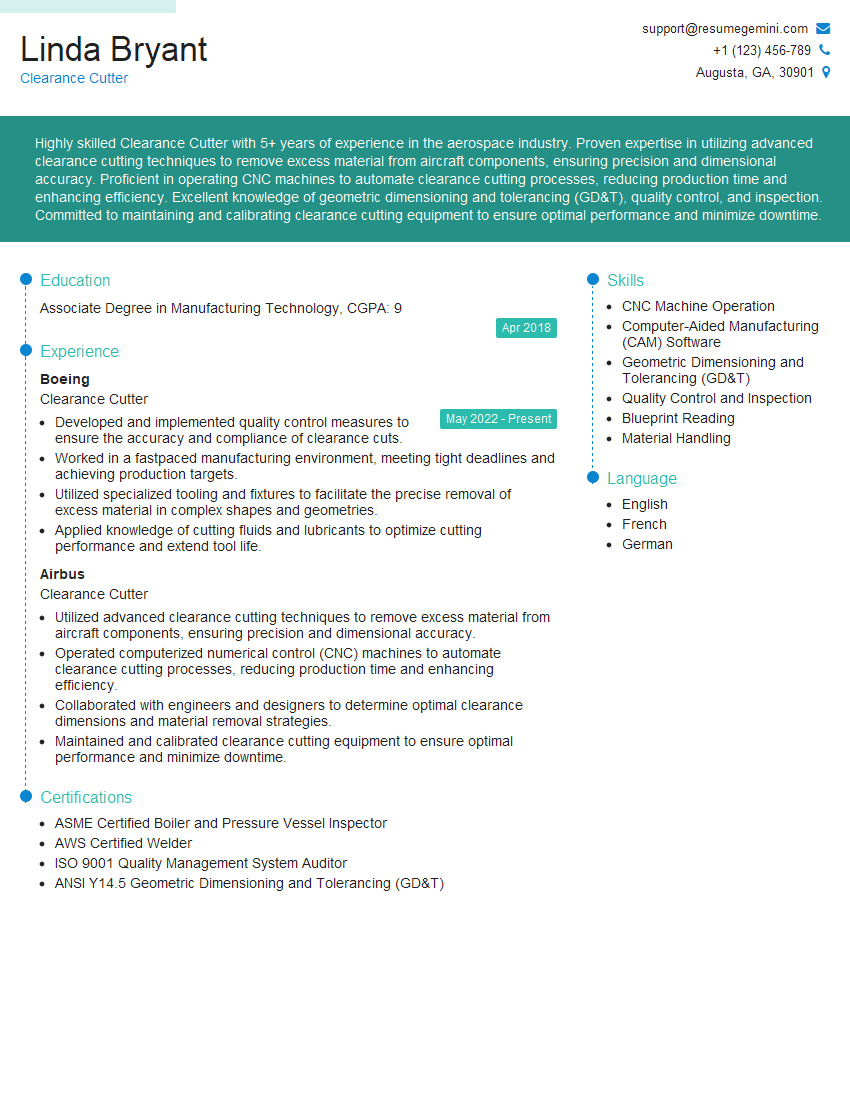

Linda Bryant

Clearance Cutter

Summary

Highly skilled Clearance Cutter with 5+ years of experience in the aerospace industry. Proven expertise in utilizing advanced clearance cutting techniques to remove excess material from aircraft components, ensuring precision and dimensional accuracy. Proficient in operating CNC machines to automate clearance cutting processes, reducing production time and enhancing efficiency. Excellent knowledge of geometric dimensioning and tolerancing (GD&T), quality control, and inspection. Committed to maintaining and calibrating clearance cutting equipment to ensure optimal performance and minimize downtime.

Education

Associate Degree in Manufacturing Technology

April 2018

Skills

- CNC Machine Operation

- Computer-Aided Manufacturing (CAM) Software

- Geometric Dimensioning and Tolerancing (GD&T)

- Quality Control and Inspection

- Blueprint Reading

- Material Handling

Work Experience

Clearance Cutter

- Developed and implemented quality control measures to ensure the accuracy and compliance of clearance cuts.

- Worked in a fastpaced manufacturing environment, meeting tight deadlines and achieving production targets.

- Utilized specialized tooling and fixtures to facilitate the precise removal of excess material in complex shapes and geometries.

- Applied knowledge of cutting fluids and lubricants to optimize cutting performance and extend tool life.

Clearance Cutter

- Utilized advanced clearance cutting techniques to remove excess material from aircraft components, ensuring precision and dimensional accuracy.

- Operated computerized numerical control (CNC) machines to automate clearance cutting processes, reducing production time and enhancing efficiency.

- Collaborated with engineers and designers to determine optimal clearance dimensions and material removal strategies.

- Maintained and calibrated clearance cutting equipment to ensure optimal performance and minimize downtime.

Certificates

- ASME Certified Boiler and Pressure Vessel Inspector

- AWS Certified Welder

- ISO 9001 Quality Management System Auditor

- ANSI Y14.5 Geometric Dimensioning and Tolerancing (GD&T)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Clearance Cutter

- Highlight your experience in operating CNC machines and utilizing advanced clearance cutting techniques.

- Quantify your accomplishments with specific metrics and results.

- Emphasize your knowledge of geometric dimensioning and tolerancing (GD&T) and quality control.

- Mention any certifications or training programs you have completed.

- Showcase your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Clearance Cutter Resume

- Utilized advanced clearance cutting techniques to remove excess material from aircraft components, ensuring precision and dimensional accuracy.

- Operated computerized numerical control (CNC) machines to automate clearance cutting processes, reducing production time and enhancing efficiency.

- Collaborated with engineers and designers to determine optimal clearance dimensions and material removal strategies.

- Maintained and calibrated clearance cutting equipment to ensure optimal performance and minimize downtime.

- Developed and implemented quality control measures to ensure the accuracy and compliance of clearance cuts.

- Worked in a fast-paced manufacturing environment, meeting tight deadlines and achieving production targets.

- Utilized specialized tooling and fixtures to facilitate the precise removal of excess material in complex shapes and geometries.

Frequently Asked Questions (FAQ’s) For Clearance Cutter

What is the primary role of a Clearance Cutter?

A Clearance Cutter is responsible for removing excess material from aircraft components using advanced clearance cutting techniques, ensuring precision and dimensional accuracy.

What skills are required to be a successful Clearance Cutter?

Essential skills include proficiency in operating CNC machines, knowledge of geometric dimensioning and tolerancing (GD&T), quality control, and inspection techniques.

What is the work environment like for a Clearance Cutter?

Clearance Cutters typically work in fast-paced manufacturing environments, meeting tight deadlines and achieving production targets.

What are the career advancement opportunities for a Clearance Cutter?

With experience and additional training, Clearance Cutters can advance to roles such as CNC Programmer, Quality Inspector, or Manufacturing Supervisor.

What is the salary range for a Clearance Cutter?

The salary range for Clearance Cutters can vary depending on experience, location, and industry. According to Indeed, the average salary for a Clearance Cutter in the United States is around $55,000 per year.

How can I become a Clearance Cutter?

To become a Clearance Cutter, you typically need an associate degree in manufacturing technology or a related field. Additionally, relevant experience in operating CNC machines and knowledge of geometric dimensioning and tolerancing (GD&T) is highly desirable.

What are some tips for writing a standout Clearance Cutter resume?

Highlight your experience, skills, and certifications in clearance cutting. Quantify your accomplishments with specific metrics and results. Showcase your knowledge of CNC machines, GD&T, and quality control. Tailor your resume to the specific requirements of each job you apply for.