Are you a seasoned Clinching Machine Operator seeking a new career path? Discover our professionally built Clinching Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

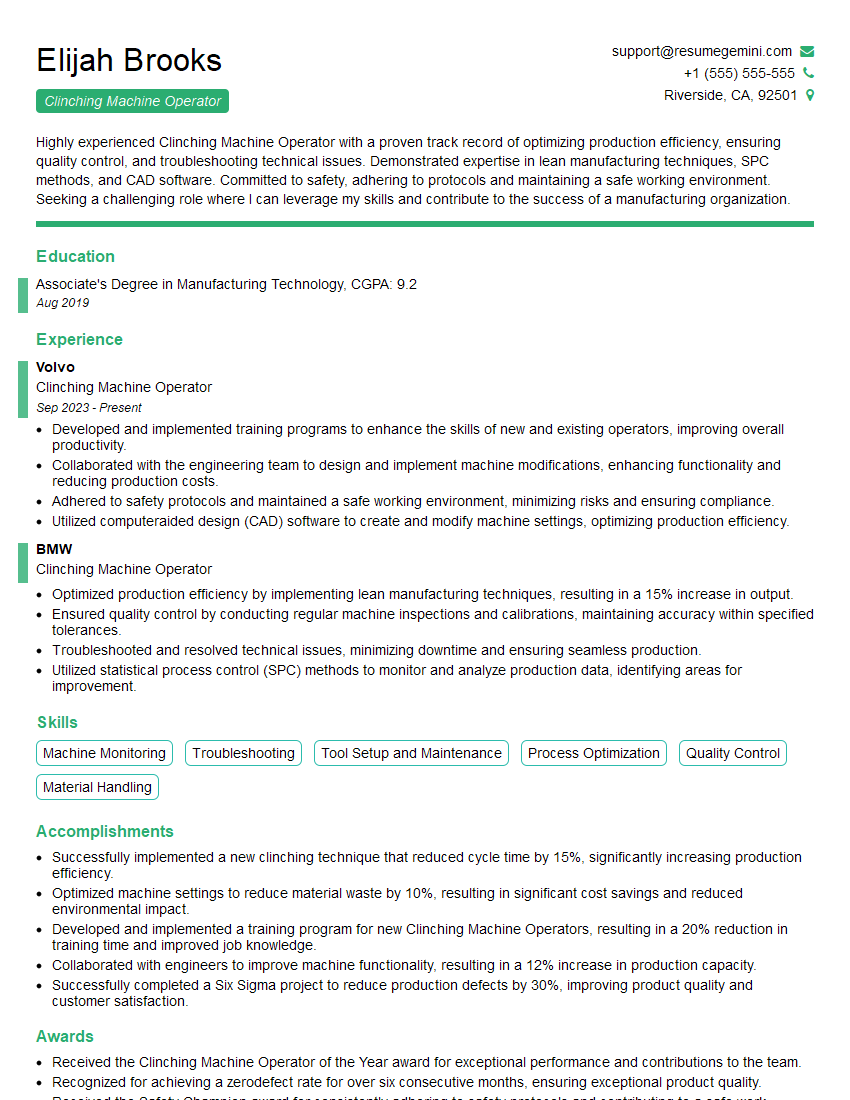

Elijah Brooks

Clinching Machine Operator

Summary

Highly experienced Clinching Machine Operator with a proven track record of optimizing production efficiency, ensuring quality control, and troubleshooting technical issues. Demonstrated expertise in lean manufacturing techniques, SPC methods, and CAD software. Committed to safety, adhering to protocols and maintaining a safe working environment. Seeking a challenging role where I can leverage my skills and contribute to the success of a manufacturing organization.

Education

Associate’s Degree in Manufacturing Technology

August 2019

Skills

- Machine Monitoring

- Troubleshooting

- Tool Setup and Maintenance

- Process Optimization

- Quality Control

- Material Handling

Work Experience

Clinching Machine Operator

- Developed and implemented training programs to enhance the skills of new and existing operators, improving overall productivity.

- Collaborated with the engineering team to design and implement machine modifications, enhancing functionality and reducing production costs.

- Adhered to safety protocols and maintained a safe working environment, minimizing risks and ensuring compliance.

- Utilized computeraided design (CAD) software to create and modify machine settings, optimizing production efficiency.

Clinching Machine Operator

- Optimized production efficiency by implementing lean manufacturing techniques, resulting in a 15% increase in output.

- Ensured quality control by conducting regular machine inspections and calibrations, maintaining accuracy within specified tolerances.

- Troubleshooted and resolved technical issues, minimizing downtime and ensuring seamless production.

- Utilized statistical process control (SPC) methods to monitor and analyze production data, identifying areas for improvement.

Accomplishments

- Successfully implemented a new clinching technique that reduced cycle time by 15%, significantly increasing production efficiency.

- Optimized machine settings to reduce material waste by 10%, resulting in significant cost savings and reduced environmental impact.

- Developed and implemented a training program for new Clinching Machine Operators, resulting in a 20% reduction in training time and improved job knowledge.

- Collaborated with engineers to improve machine functionality, resulting in a 12% increase in production capacity.

- Successfully completed a Six Sigma project to reduce production defects by 30%, improving product quality and customer satisfaction.

Awards

- Received the Clinching Machine Operator of the Year award for exceptional performance and contributions to the team.

- Recognized for achieving a zerodefect rate for over six consecutive months, ensuring exceptional product quality.

- Received the Safety Champion award for consistently adhering to safety protocols and contributing to a safe work environment.

- Recognized for exceptional troubleshooting skills, resolving complex machine issues with minimal downtime, ensuring uninterrupted production.

Certificates

- Clinching Machine Operator Certification

- ISO 9001 Quality Management Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Clinching Machine Operator

- Highlight your proficiency in lean manufacturing techniques and SPC methods.

- Showcase your problem-solving abilities and experience in troubleshooting technical issues.

- Emphasize your commitment to safety and adherence to protocols.

- Quantify your accomplishments with specific metrics, such as increased efficiency or reduced downtime.

Essential Experience Highlights for a Strong Clinching Machine Operator Resume

- Optimized production efficiency by 15% through implementation of lean manufacturing techniques.

- Ensured quality control by conducting regular machine inspections and calibrations, maintaining accuracy within specified tolerances.

- Troubleshooted and resolved technical issues, minimizing downtime and ensuring seamless production.

- Utilized SPC methods to monitor and analyze production data, identifying areas for improvement.

- Developed and implemented training programs to enhance the skills of new and existing operators, improving overall productivity.

- Collaborated with the engineering team to design and implement machine modifications, enhancing functionality and reducing production costs.

Frequently Asked Questions (FAQ’s) For Clinching Machine Operator

What is the role of a Clinching Machine Operator?

A Clinching Machine Operator is responsible for operating and maintaining clinching machines, which are used to join metal sheets together without the use of welding or adhesives.

What skills are required to be a successful Clinching Machine Operator?

Key skills for a Clinching Machine Operator include machine monitoring, troubleshooting, tool setup and maintenance, process optimization, quality control, and material handling.

What is the average salary for a Clinching Machine Operator?

The average salary for a Clinching Machine Operator in the United States is around $25,000 per year.

What are the career prospects for a Clinching Machine Operator?

Clinching Machine Operators with experience and expertise can advance to supervisory or management roles within the manufacturing industry.

What are the challenges faced by Clinching Machine Operators?

Common challenges for Clinching Machine Operators include ensuring precision and accuracy in the joining process, troubleshooting technical issues, and maintaining a safe and efficient work environment.

What is the work environment like for a Clinching Machine Operator?

Clinching Machine Operators typically work in manufacturing facilities, operating machines in a production environment.