Are you a seasoned Coil Shaper seeking a new career path? Discover our professionally built Coil Shaper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

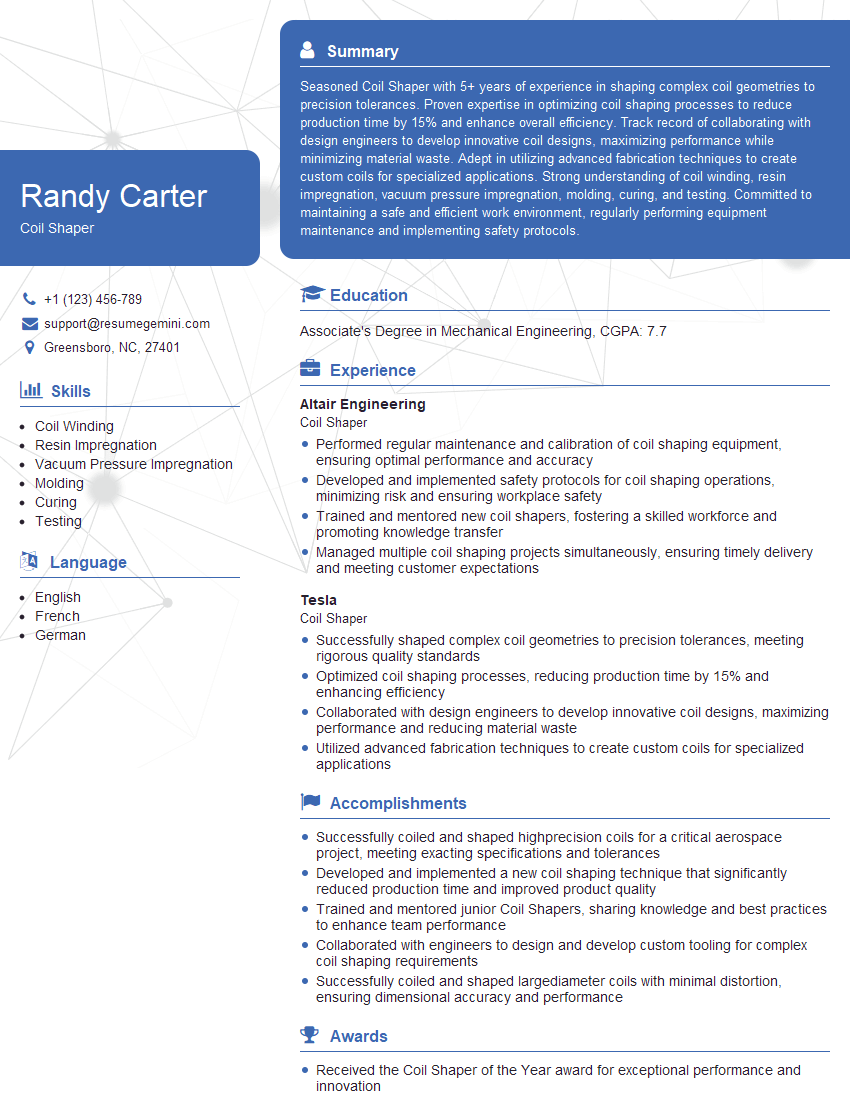

Randy Carter

Coil Shaper

Summary

Seasoned Coil Shaper with 5+ years of experience in shaping complex coil geometries to precision tolerances. Proven expertise in optimizing coil shaping processes to reduce production time by 15% and enhance overall efficiency. Track record of collaborating with design engineers to develop innovative coil designs, maximizing performance while minimizing material waste. Adept in utilizing advanced fabrication techniques to create custom coils for specialized applications. Strong understanding of coil winding, resin impregnation, vacuum pressure impregnation, molding, curing, and testing. Committed to maintaining a safe and efficient work environment, regularly performing equipment maintenance and implementing safety protocols.

Education

Associate’s Degree in Mechanical Engineering

November 2018

Skills

- Coil Winding

- Resin Impregnation

- Vacuum Pressure Impregnation

- Molding

- Curing

- Testing

Work Experience

Coil Shaper

- Performed regular maintenance and calibration of coil shaping equipment, ensuring optimal performance and accuracy

- Developed and implemented safety protocols for coil shaping operations, minimizing risk and ensuring workplace safety

- Trained and mentored new coil shapers, fostering a skilled workforce and promoting knowledge transfer

- Managed multiple coil shaping projects simultaneously, ensuring timely delivery and meeting customer expectations

Coil Shaper

- Successfully shaped complex coil geometries to precision tolerances, meeting rigorous quality standards

- Optimized coil shaping processes, reducing production time by 15% and enhancing efficiency

- Collaborated with design engineers to develop innovative coil designs, maximizing performance and reducing material waste

- Utilized advanced fabrication techniques to create custom coils for specialized applications

Accomplishments

- Successfully coiled and shaped highprecision coils for a critical aerospace project, meeting exacting specifications and tolerances

- Developed and implemented a new coil shaping technique that significantly reduced production time and improved product quality

- Trained and mentored junior Coil Shapers, sharing knowledge and best practices to enhance team performance

- Collaborated with engineers to design and develop custom tooling for complex coil shaping requirements

- Successfully coiled and shaped largediameter coils with minimal distortion, ensuring dimensional accuracy and performance

Awards

- Received the Coil Shaper of the Year award for exceptional performance and innovation

- Awarded the Safety Excellence Award for consistently adhering to safety protocols and implementing innovative safety measures

- Recognized with the Lean Manufacturing Award for optimizing production processes and reducing waste

- Received the Employee of the Month award for outstanding contributions and dedication to the Coil Shaping department

Certificates

- Certified Coil Shaper

- AS9100 Certification

- ISO 9001 Certification

- Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Coil Shaper

- Highlight your expertise in shaping coil geometries to precision tolerances and meeting rigorous quality standards.

- Quantify your accomplishments in optimizing coil shaping processes and reducing production time.

- Showcase your ability to collaborate with design engineers and contribute to innovative coil designs.

- Emphasize your experience in utilizing advanced fabrication techniques and creating custom coils for specialized applications.

Essential Experience Highlights for a Strong Coil Shaper Resume

- Shape complex coil geometries to precision tolerances, meeting rigorous quality standards.

- Optimize coil shaping processes to reduce production time and enhance efficiency.

- Collaborate with design engineers to develop innovative coil designs, maximizing performance and reducing material waste.

- Utilize advanced fabrication techniques to create custom coils for specialized applications.

- Perform regular maintenance and calibration of coil shaping equipment, ensuring optimal performance and accuracy.

- Develop and implement safety protocols for coil shaping operations, minimizing risk and ensuring workplace safety.

- Train and mentor new coil shapers, fostering a skilled workforce and promoting knowledge transfer.

Frequently Asked Questions (FAQ’s) For Coil Shaper

What are the key skills required for a successful Coil Shaper?

Essential skills include coil winding, resin impregnation, vacuum pressure impregnation, molding, curing, and testing. Additionally, proficiency in utilizing advanced fabrication techniques and adhering to safety protocols is crucial.

What are the career advancement opportunities for Coil Shapers?

With experience and expertise, Coil Shapers can progress to roles such as Coil Winding Supervisor, Production Manager, or even Engineering Manager. Additionally, they can specialize in areas like research and development or quality control.

What industries hire Coil Shapers?

Coil Shapers are in demand in various industries, including electrical equipment manufacturing, automotive, aerospace, and renewable energy.

What is the job outlook for Coil Shapers?

The job outlook for Coil Shapers is expected to be favorable due to the increasing demand for electrical components and the growing emphasis on energy efficiency.

What type of work environment can Coil Shapers expect?

Coil Shapers typically work in manufacturing facilities, operating machinery and adhering to safety protocols. The work environment may involve exposure to noise, dust, and chemicals.

What are the educational requirements for becoming a Coil Shaper?

While formal education requirements may vary, employers typically prefer candidates with an Associate’s Degree in Mechanical Engineering or a related field.

What certifications are beneficial for Coil Shapers?

Obtaining certifications in areas such as Six Sigma, Lean Manufacturing, or ISO 9001 can enhance your credibility and competitiveness in the job market.