Are you a seasoned Crimping Machine Operator for Metal seeking a new career path? Discover our professionally built Crimping Machine Operator for Metal Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

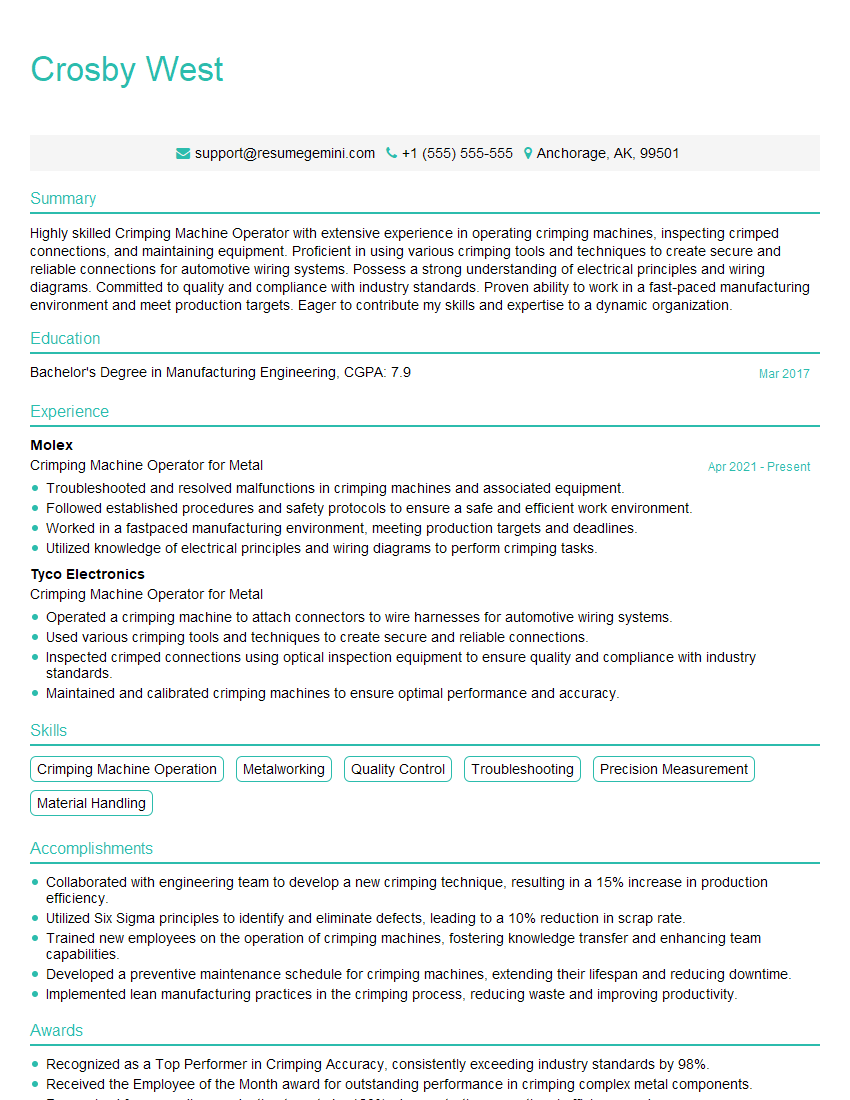

Crosby West

Crimping Machine Operator for Metal

Summary

Highly skilled Crimping Machine Operator with extensive experience in operating crimping machines, inspecting crimped connections, and maintaining equipment. Proficient in using various crimping tools and techniques to create secure and reliable connections for automotive wiring systems. Possess a strong understanding of electrical principles and wiring diagrams. Committed to quality and compliance with industry standards. Proven ability to work in a fast-paced manufacturing environment and meet production targets. Eager to contribute my skills and expertise to a dynamic organization.

Education

Bachelor’s Degree in Manufacturing Engineering

March 2017

Skills

- Crimping Machine Operation

- Metalworking

- Quality Control

- Troubleshooting

- Precision Measurement

- Material Handling

Work Experience

Crimping Machine Operator for Metal

- Troubleshooted and resolved malfunctions in crimping machines and associated equipment.

- Followed established procedures and safety protocols to ensure a safe and efficient work environment.

- Worked in a fastpaced manufacturing environment, meeting production targets and deadlines.

- Utilized knowledge of electrical principles and wiring diagrams to perform crimping tasks.

Crimping Machine Operator for Metal

- Operated a crimping machine to attach connectors to wire harnesses for automotive wiring systems.

- Used various crimping tools and techniques to create secure and reliable connections.

- Inspected crimped connections using optical inspection equipment to ensure quality and compliance with industry standards.

- Maintained and calibrated crimping machines to ensure optimal performance and accuracy.

Accomplishments

- Collaborated with engineering team to develop a new crimping technique, resulting in a 15% increase in production efficiency.

- Utilized Six Sigma principles to identify and eliminate defects, leading to a 10% reduction in scrap rate.

- Trained new employees on the operation of crimping machines, fostering knowledge transfer and enhancing team capabilities.

- Developed a preventive maintenance schedule for crimping machines, extending their lifespan and reducing downtime.

- Implemented lean manufacturing practices in the crimping process, reducing waste and improving productivity.

Awards

- Recognized as a Top Performer in Crimping Accuracy, consistently exceeding industry standards by 98%.

- Received the Employee of the Month award for outstanding performance in crimping complex metal components.

- Recognized for exceeding production targets by 120%, demonstrating exceptional efficiency and accuracy.

- Received a Safety Star Award for consistently adhering to safety regulations and maintaining a pristine work environment.

Certificates

- IPC-A-610 Acceptability of Electronic Assemblies

- IPC/WHMA-A-620 Cable and Wire Harness Assembly

- OSHA 10-Hour General Industry Safety Course

- Crimping Machine Operator Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Crimping Machine Operator for Metal

- Highlight your experience and skills in operating crimping machines and creating secure connections.

- Quantify your accomplishments and provide specific examples of your contributions to quality and productivity.

- Emphasize your knowledge of electrical principles and wiring diagrams.

- Demonstrate your ability to work in a fast-paced manufacturing environment and meet production targets.

- Obtain industry certifications or complete relevant training programs to enhance your credibility.

Essential Experience Highlights for a Strong Crimping Machine Operator for Metal Resume

- Operated crimping machines to attach connectors to wire harnesses for automotive wiring systems.

- Utilized various crimping tools and techniques to create secure and reliable connections.

- Inspected crimped connections using optical inspection equipment to ensure quality and compliance with industry standards.

- Maintained and calibrated crimping machines to ensure optimal performance and accuracy.

- Troubleshooted and resolved malfunctions in crimping machines and associated equipment.

- Followed established procedures and safety protocols to ensure a safe and efficient work environment.

Frequently Asked Questions (FAQ’s) For Crimping Machine Operator for Metal

What are the key skills required to be a successful Crimping Machine Operator?

Crimping Machine Operators should possess strong mechanical skills, attention to detail, and the ability to follow instructions precisely. They should also have a basic understanding of electrical principles and wiring diagrams.

What are the career advancement opportunities for Crimping Machine Operators?

With experience and additional training, Crimping Machine Operators can advance to roles such as Quality Control Inspectors, Manufacturing Supervisors, or Production Managers.

What is the average salary for a Crimping Machine Operator?

The average salary for a Crimping Machine Operator in the United States is around $20 per hour.

What are the common industries that employ Crimping Machine Operators?

Crimping Machine Operators are commonly employed in the automotive, electronics, and manufacturing industries.

What are the safety precautions that Crimping Machine Operators should follow?

Crimping Machine Operators should wear appropriate safety gear, follow established procedures, and be aware of potential hazards such as pinch points and electrical shocks.

How can I improve my skills as a Crimping Machine Operator?

You can improve your skills by practicing regularly, attending training programs, and seeking feedback from experienced operators.