Are you a seasoned Machining Associate seeking a new career path? Discover our professionally built Machining Associate Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

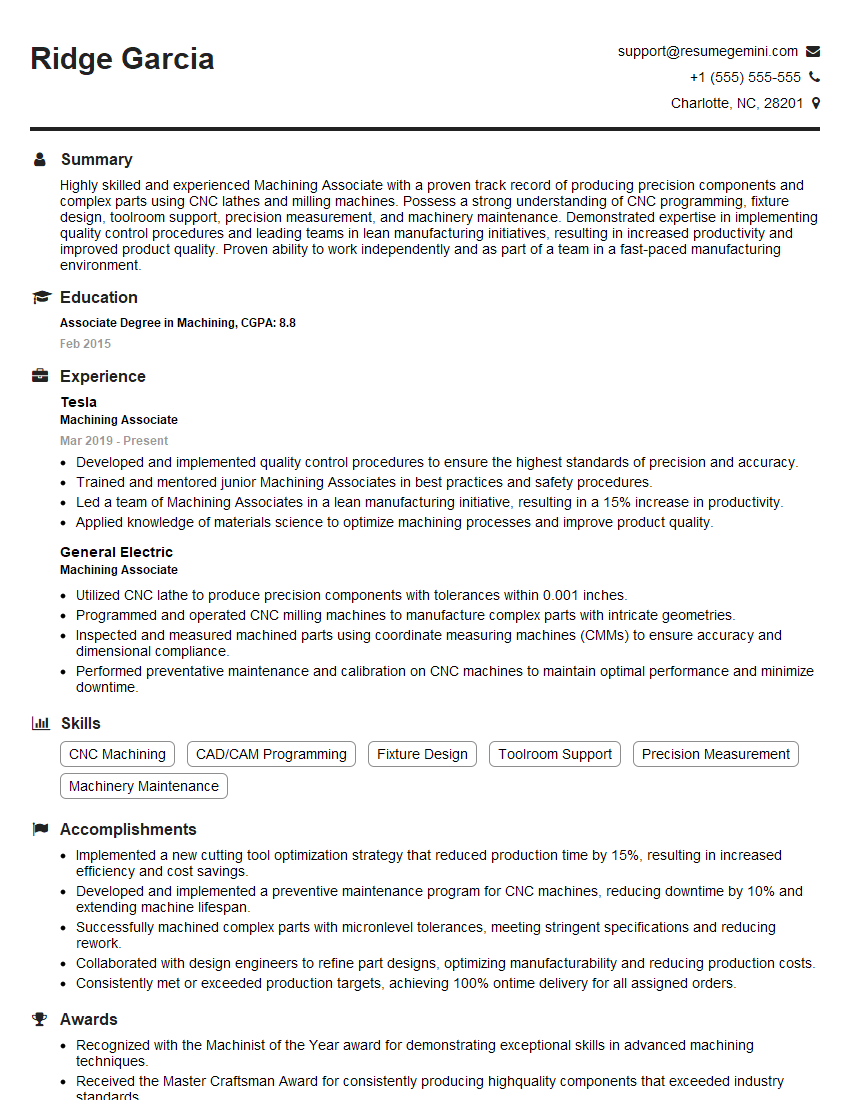

Ridge Garcia

Machining Associate

Summary

Highly skilled and experienced Machining Associate with a proven track record of producing precision components and complex parts using CNC lathes and milling machines. Possess a strong understanding of CNC programming, fixture design, toolroom support, precision measurement, and machinery maintenance. Demonstrated expertise in implementing quality control procedures and leading teams in lean manufacturing initiatives, resulting in increased productivity and improved product quality. Proven ability to work independently and as part of a team in a fast-paced manufacturing environment.

Education

Associate Degree in Machining

February 2015

Skills

- CNC Machining

- CAD/CAM Programming

- Fixture Design

- Toolroom Support

- Precision Measurement

- Machinery Maintenance

Work Experience

Machining Associate

- Developed and implemented quality control procedures to ensure the highest standards of precision and accuracy.

- Trained and mentored junior Machining Associates in best practices and safety procedures.

- Led a team of Machining Associates in a lean manufacturing initiative, resulting in a 15% increase in productivity.

- Applied knowledge of materials science to optimize machining processes and improve product quality.

Machining Associate

- Utilized CNC lathe to produce precision components with tolerances within 0.001 inches.

- Programmed and operated CNC milling machines to manufacture complex parts with intricate geometries.

- Inspected and measured machined parts using coordinate measuring machines (CMMs) to ensure accuracy and dimensional compliance.

- Performed preventative maintenance and calibration on CNC machines to maintain optimal performance and minimize downtime.

Accomplishments

- Implemented a new cutting tool optimization strategy that reduced production time by 15%, resulting in increased efficiency and cost savings.

- Developed and implemented a preventive maintenance program for CNC machines, reducing downtime by 10% and extending machine lifespan.

- Successfully machined complex parts with micronlevel tolerances, meeting stringent specifications and reducing rework.

- Collaborated with design engineers to refine part designs, optimizing manufacturability and reducing production costs.

- Consistently met or exceeded production targets, achieving 100% ontime delivery for all assigned orders.

Awards

- Recognized with the Machinist of the Year award for demonstrating exceptional skills in advanced machining techniques.

- Received the Master Craftsman Award for consistently producing highquality components that exceeded industry standards.

- Awarded the Excellence in Precision Machining certification for proficiency in operating CNC machines with extreme accuracy.

- Received the Safety Excellence Award for adhering to all safety protocols and contributing to a zeroaccident work environment.

Certificates

- Certified Machinist

- ISO 9001

- ASME B16.5

- ANSI/ASME Y14.5M

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Machining Associate

- Highlight your experience in CNC programming and operation, especially if you have worked with multiple types of CNC machines.

- Showcase your knowledge of quality control procedures and your ability to maintain high standards of precision.

- Emphasize your teamwork and leadership skills, as Machining Associates often work in collaborative environments.

- Quantify your accomplishments whenever possible, using metrics to demonstrate the impact of your contributions.

Essential Experience Highlights for a Strong Machining Associate Resume

- Operate CNC lathes and milling machines to produce precision components and complex parts according to specifications

- Program and optimize CNC machines using CAD/CAM software

- Inspect and measure machined parts using coordinate measuring machines (CMMs) to ensure accuracy

- Perform preventative maintenance and calibration on CNC machines

- Develop and implement quality control procedures to maintain high standards of precision and accuracy

- Collaborate with engineers and designers to troubleshoot and resolve technical issues

- Lead and mentor junior Machining Associates in best practices and safety procedures

Frequently Asked Questions (FAQ’s) For Machining Associate

What is the expected salary range for a Machining Associate?

The salary range for Machining Associates can vary depending on experience, location, and industry. According to Salary.com, the average salary for a Machining Associate in the United States is around $25,000 to $45,000 per year.

What are the career advancement opportunities for Machining Associates?

Machining Associates can advance their careers by gaining experience and developing their skills. They can become CNC programmers, supervisors, or quality control inspectors. With additional education and training, they can also move into management or engineering roles.

What are the job outlook and employment trends for Machining Associates?

The job outlook for Machining Associates is expected to be good in the coming years. The increasing demand for precision-machined parts in various industries, such as aerospace, automotive, and medical, is driving the need for skilled Machining Associates.

What are the key skills that employers look for in Machining Associates?

Employers look for Machining Associates who have strong technical skills in CNC programming, operation, and maintenance. They also value candidates who are detail-oriented, have a strong work ethic, and are able to work independently and as part of a team.

How can I prepare for a career as a Machining Associate?

To prepare for a career as a Machining Associate, you can take courses in CNC programming, operation, and maintenance. You can also gain experience by working in a machine shop or through apprenticeships.

What are the safety precautions that Machining Associates should follow?

Machining Associates should always follow proper safety precautions when working with machinery. This includes wearing appropriate protective gear, such as safety glasses, earplugs, and gloves. They should also be aware of the hazards associated with their work, such as moving machinery, sharp tools, and hazardous chemicals.

What are the different types of CNC machines that Machining Associates may work with?

Machining Associates may work with a variety of CNC machines, including CNC lathes, CNC milling machines, and CNC grinders. Each type of machine is used for different purposes, and Machining Associates should be familiar with the operation and maintenance of each type of machine.