Are you a seasoned Metal Shaping Machine Operator seeking a new career path? Discover our professionally built Metal Shaping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

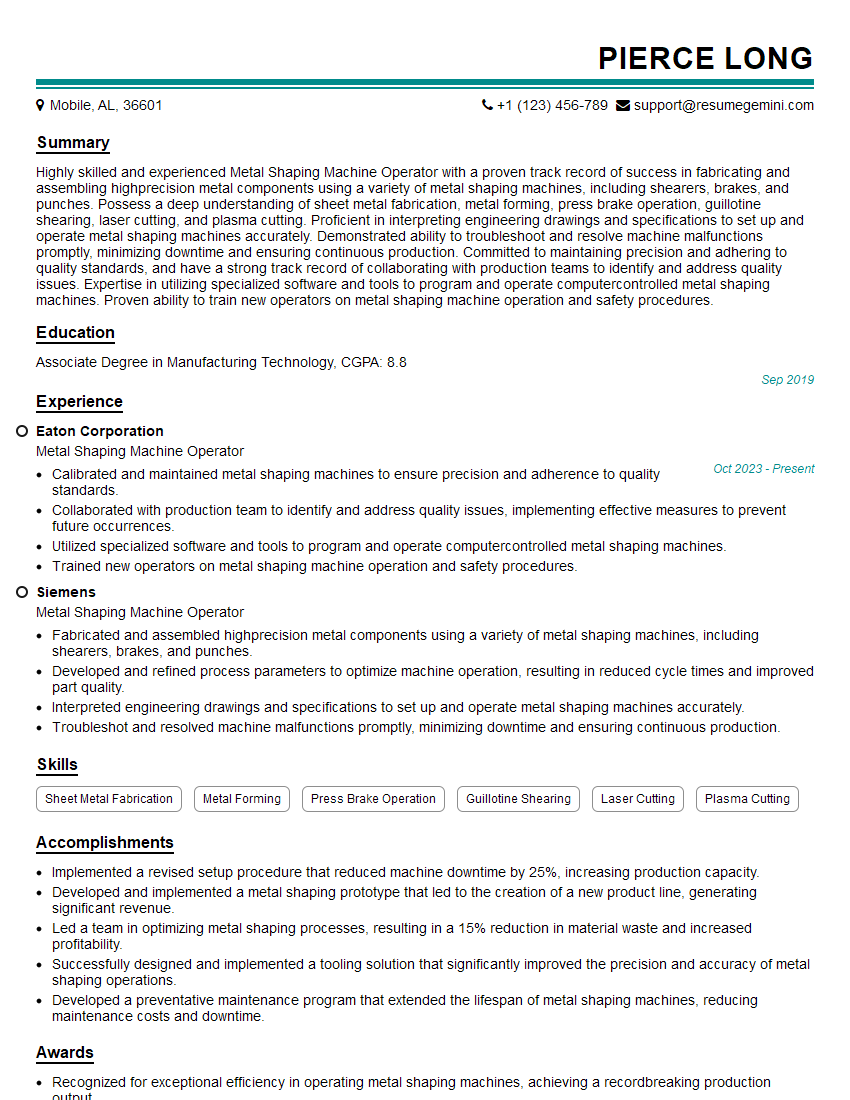

Pierce Long

Metal Shaping Machine Operator

Summary

Highly skilled and experienced Metal Shaping Machine Operator with a proven track record of success in fabricating and assembling highprecision metal components using a variety of metal shaping machines, including shearers, brakes, and punches. Possess a deep understanding of sheet metal fabrication, metal forming, press brake operation, guillotine shearing, laser cutting, and plasma cutting. Proficient in interpreting engineering drawings and specifications to set up and operate metal shaping machines accurately. Demonstrated ability to troubleshoot and resolve machine malfunctions promptly, minimizing downtime and ensuring continuous production. Committed to maintaining precision and adhering to quality standards, and have a strong track record of collaborating with production teams to identify and address quality issues. Expertise in utilizing specialized software and tools to program and operate computercontrolled metal shaping machines. Proven ability to train new operators on metal shaping machine operation and safety procedures.

Education

Associate Degree in Manufacturing Technology

September 2019

Skills

- Sheet Metal Fabrication

- Metal Forming

- Press Brake Operation

- Guillotine Shearing

- Laser Cutting

- Plasma Cutting

Work Experience

Metal Shaping Machine Operator

- Calibrated and maintained metal shaping machines to ensure precision and adherence to quality standards.

- Collaborated with production team to identify and address quality issues, implementing effective measures to prevent future occurrences.

- Utilized specialized software and tools to program and operate computercontrolled metal shaping machines.

- Trained new operators on metal shaping machine operation and safety procedures.

Metal Shaping Machine Operator

- Fabricated and assembled highprecision metal components using a variety of metal shaping machines, including shearers, brakes, and punches.

- Developed and refined process parameters to optimize machine operation, resulting in reduced cycle times and improved part quality.

- Interpreted engineering drawings and specifications to set up and operate metal shaping machines accurately.

- Troubleshot and resolved machine malfunctions promptly, minimizing downtime and ensuring continuous production.

Accomplishments

- Implemented a revised setup procedure that reduced machine downtime by 25%, increasing production capacity.

- Developed and implemented a metal shaping prototype that led to the creation of a new product line, generating significant revenue.

- Led a team in optimizing metal shaping processes, resulting in a 15% reduction in material waste and increased profitability.

- Successfully designed and implemented a tooling solution that significantly improved the precision and accuracy of metal shaping operations.

- Developed a preventative maintenance program that extended the lifespan of metal shaping machines, reducing maintenance costs and downtime.

Awards

- Recognized for exceptional efficiency in operating metal shaping machines, achieving a recordbreaking production output.

- Recipient of the Operator of the Year award for consistently exceeding performance targets and maintaining highquality standards.

- Honored for outstanding contributions to the metal shaping industry through innovation and technical expertise.

- Recognized for exceptional safety performance, maintaining a spotless record of accident and incident prevention.

Certificates

- Certified Metal Forming Operator (CMFO)

- Certified Press Brake Operator (CPBO)

- Certified Laser Cutting Operator (CLCO)

- Certified Plasma Cutting Operator (CPCO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Shaping Machine Operator

- Highlight your experience and skills in operating and maintaining various metal shaping machines.

- Showcase your knowledge of sheet metal fabrication, metal forming, and other relevant industry practices.

- Emphasize your ability to interpret engineering drawings and specifications and set up machines accordingly.

- Provide examples of how you have optimized machine operation and improved part quality.

- Demonstrate your commitment to quality control and safety procedures.

Essential Experience Highlights for a Strong Metal Shaping Machine Operator Resume

- Fabricate and assemble highprecision metal components using a variety of metal shaping machines, including shearers, brakes, and punches.

- Develop and refine process parameters to optimize machine operation, resulting in reduced cycle times and improved part quality.

- Interpret engineering drawings and specifications to set up and operate metal shaping machines accurately.

- Troubleshoot and resolve machine malfunctions promptly, minimizing downtime and ensuring continuous production.

- Calibrate and maintain metal shaping machines to ensure precision and adherence to quality standards.

- Collaborate with production team to identify and address quality issues, implementing effective measures to prevent future occurrences.

Frequently Asked Questions (FAQ’s) For Metal Shaping Machine Operator

What are the key skills required for a Metal Shaping Machine Operator?

The key skills required for a Metal Shaping Machine Operator include sheet metal fabrication, metal forming, press brake operation, guillotine shearing, laser cutting, and plasma cutting.

What are the typical job responsibilities of a Metal Shaping Machine Operator?

The typical job responsibilities of a Metal Shaping Machine Operator include fabricating and assembling metal components, interpreting engineering drawings, setting up and operating machines, troubleshooting and resolving malfunctions, and maintaining equipment.

What are the educational qualifications required to become a Metal Shaping Machine Operator?

The minimum educational qualification required to become a Metal Shaping Machine Operator is typically a high school diploma or equivalent. However, some employers may prefer candidates with an associate degree in manufacturing technology or a related field.

What are the career advancement opportunities for a Metal Shaping Machine Operator?

With experience and additional training, a Metal Shaping Machine Operator can advance to positions such as Production Supervisor, Quality Control Inspector, or Manufacturing Engineer.

What is the average salary for a Metal Shaping Machine Operator?

The average salary for a Metal Shaping Machine Operator in the United States is around $45,000 per year.