Are you a seasoned Metal Stamping Machine Operator seeking a new career path? Discover our professionally built Metal Stamping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

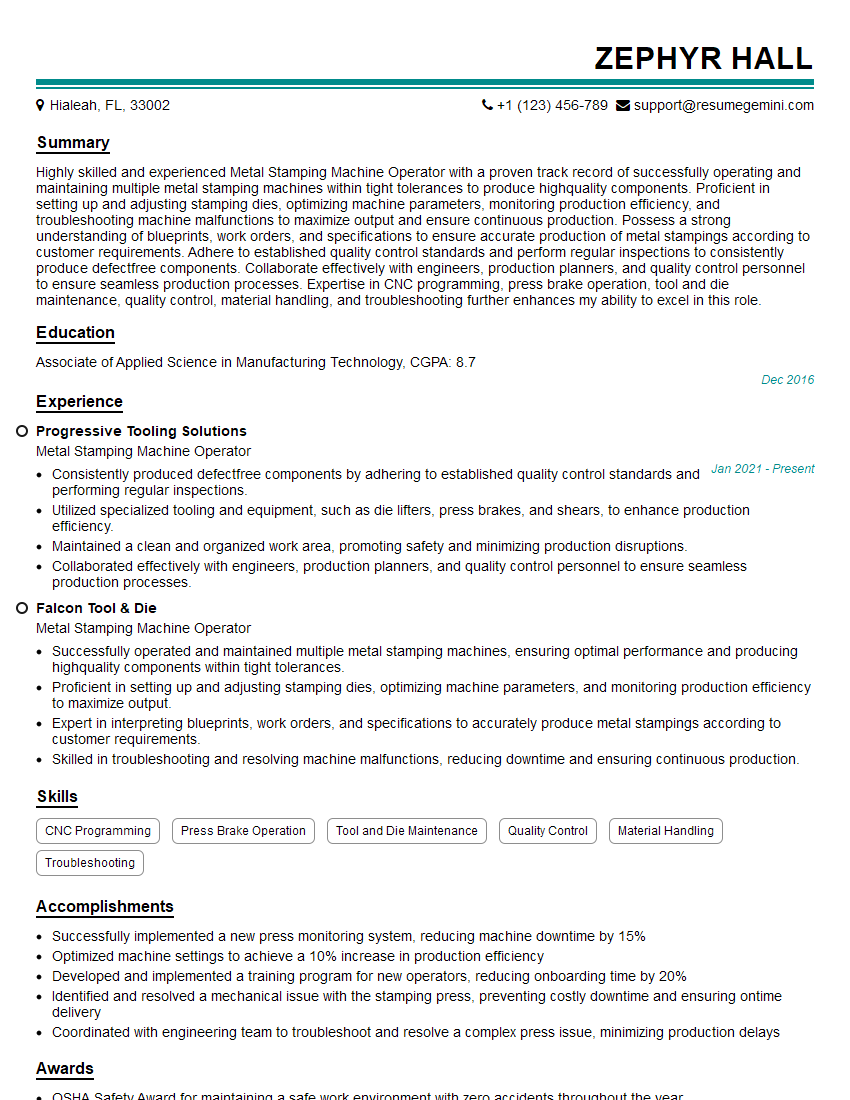

Zephyr Hall

Metal Stamping Machine Operator

Summary

Highly skilled and experienced Metal Stamping Machine Operator with a proven track record of successfully operating and maintaining multiple metal stamping machines within tight tolerances to produce highquality components. Proficient in setting up and adjusting stamping dies, optimizing machine parameters, monitoring production efficiency, and troubleshooting machine malfunctions to maximize output and ensure continuous production. Possess a strong understanding of blueprints, work orders, and specifications to ensure accurate production of metal stampings according to customer requirements. Adhere to established quality control standards and perform regular inspections to consistently produce defectfree components. Collaborate effectively with engineers, production planners, and quality control personnel to ensure seamless production processes. Expertise in CNC programming, press brake operation, tool and die maintenance, quality control, material handling, and troubleshooting further enhances my ability to excel in this role.

Education

Associate of Applied Science in Manufacturing Technology

December 2016

Skills

- CNC Programming

- Press Brake Operation

- Tool and Die Maintenance

- Quality Control

- Material Handling

- Troubleshooting

Work Experience

Metal Stamping Machine Operator

- Consistently produced defectfree components by adhering to established quality control standards and performing regular inspections.

- Utilized specialized tooling and equipment, such as die lifters, press brakes, and shears, to enhance production efficiency.

- Maintained a clean and organized work area, promoting safety and minimizing production disruptions.

- Collaborated effectively with engineers, production planners, and quality control personnel to ensure seamless production processes.

Metal Stamping Machine Operator

- Successfully operated and maintained multiple metal stamping machines, ensuring optimal performance and producing highquality components within tight tolerances.

- Proficient in setting up and adjusting stamping dies, optimizing machine parameters, and monitoring production efficiency to maximize output.

- Expert in interpreting blueprints, work orders, and specifications to accurately produce metal stampings according to customer requirements.

- Skilled in troubleshooting and resolving machine malfunctions, reducing downtime and ensuring continuous production.

Accomplishments

- Successfully implemented a new press monitoring system, reducing machine downtime by 15%

- Optimized machine settings to achieve a 10% increase in production efficiency

- Developed and implemented a training program for new operators, reducing onboarding time by 20%

- Identified and resolved a mechanical issue with the stamping press, preventing costly downtime and ensuring ontime delivery

- Coordinated with engineering team to troubleshoot and resolve a complex press issue, minimizing production delays

Awards

- OSHA Safety Award for maintaining a safe work environment with zero accidents throughout the year

- Employee of the Month for consistently exceeding production targets and maintaining highquality standards

- Safety Recognition Award for proactive identification and reporting of potential hazards

- Performance Excellence Award for achieving outstanding results in meeting production goals

Certificates

- Certified Stamping Technician (CST)

- OSHA 30-Hour Card

- Lean Six Sigma Green Belt

- ISO 9001 Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Stamping Machine Operator

- Highlight your experience and skills in operating and maintaining metal stamping machines.

- Showcase your proficiency in setting up and adjusting stamping dies, optimizing machine parameters, and monitoring production efficiency.

- Emphasize your ability to interpret blueprints, work orders, and specifications to accurately produce metal stampings.

- Include your troubleshooting and resolving machine malfunctions to minimize downtime and ensure continuous production.

Essential Experience Highlights for a Strong Metal Stamping Machine Operator Resume

- Operate and maintain multiple metal stamping machines to produce highquality components within tight tolerances.

- Set up and adjust stamping dies, optimize machine parameters, and monitor production efficiency to maximize output.

- Interpret blueprints, work orders, and specifications to accurately produce metal stampings according to customer requirements.

- Troubleshoot and resolve machine malfunctions to reduce downtime and ensure continuous production.

- Perform regular inspections and adhere to established quality control standards to produce defectfree components.

- Utilize specialized tooling and equipment, such as die lifters, press brakes, and shears, to enhance production efficiency.

- Collaborate effectively with engineers, production planners, and quality control personnel to ensure seamless production processes.

Frequently Asked Questions (FAQ’s) For Metal Stamping Machine Operator

What are the key skills and responsibilities of a Metal Stamping Machine Operator?

Key skills and responsibilities include operating and maintaining metal stamping machines, setting up and adjusting stamping dies, optimizing machine parameters, monitoring production efficiency, troubleshooting machine malfunctions, performing regular inspections, adhering to quality control standards, and collaborating with engineers and production planners.

What industries typically employ Metal Stamping Machine Operators?

Metal Stamping Machine Operators are employed in various industries, including automotive, aerospace, construction, electronics, and manufacturing.

What is the average salary for a Metal Stamping Machine Operator?

The average salary for a Metal Stamping Machine Operator varies depending on experience, location, and industry, but typically ranges from $20 to $30 per hour.

What are the career advancement opportunities for a Metal Stamping Machine Operator?

With experience and additional training, Metal Stamping Machine Operators can advance to positions such as Production Supervisor, Quality Control Inspector, or Tool and Die Maker.

What type of training is required to become a Metal Stamping Machine Operator?

Most Metal Stamping Machine Operators receive onthejob training, but some may complete a formal apprenticeship program or attend a technical school.

What are the safety precautions that Metal Stamping Machine Operators must follow?

Metal Stamping Machine Operators must follow safety precautions such as wearing appropriate safety gear, being aware of moving machinery, and following lockout/tagout procedures.

What are the challenges faced by Metal Stamping Machine Operators?

Metal Stamping Machine Operators may face challenges such as working in a noisy and potentially hazardous environment, meeting tight production deadlines, and troubleshooting complex machine malfunctions.