Are you a seasoned Metal Stamper seeking a new career path? Discover our professionally built Metal Stamper Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

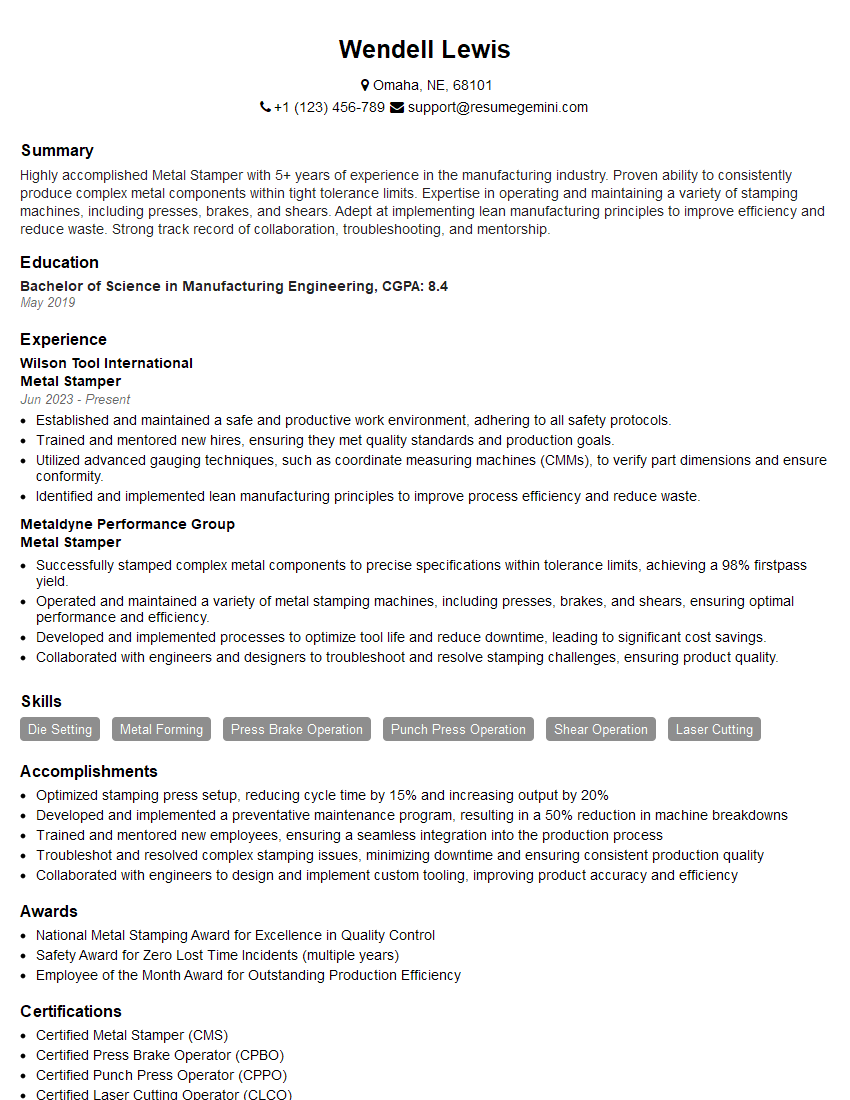

Wendell Lewis

Metal Stamper

Summary

Highly accomplished Metal Stamper with 5+ years of experience in the manufacturing industry. Proven ability to consistently produce complex metal components within tight tolerance limits. Expertise in operating and maintaining a variety of stamping machines, including presses, brakes, and shears. Adept at implementing lean manufacturing principles to improve efficiency and reduce waste. Strong track record of collaboration, troubleshooting, and mentorship.

Education

Bachelor of Science in Manufacturing Engineering

May 2019

Skills

- Die Setting

- Metal Forming

- Press Brake Operation

- Punch Press Operation

- Shear Operation

- Laser Cutting

Work Experience

Metal Stamper

- Established and maintained a safe and productive work environment, adhering to all safety protocols.

- Trained and mentored new hires, ensuring they met quality standards and production goals.

- Utilized advanced gauging techniques, such as coordinate measuring machines (CMMs), to verify part dimensions and ensure conformity.

- Identified and implemented lean manufacturing principles to improve process efficiency and reduce waste.

Metal Stamper

- Successfully stamped complex metal components to precise specifications within tolerance limits, achieving a 98% firstpass yield.

- Operated and maintained a variety of metal stamping machines, including presses, brakes, and shears, ensuring optimal performance and efficiency.

- Developed and implemented processes to optimize tool life and reduce downtime, leading to significant cost savings.

- Collaborated with engineers and designers to troubleshoot and resolve stamping challenges, ensuring product quality.

Accomplishments

- Optimized stamping press setup, reducing cycle time by 15% and increasing output by 20%

- Developed and implemented a preventative maintenance program, resulting in a 50% reduction in machine breakdowns

- Trained and mentored new employees, ensuring a seamless integration into the production process

- Troubleshot and resolved complex stamping issues, minimizing downtime and ensuring consistent production quality

- Collaborated with engineers to design and implement custom tooling, improving product accuracy and efficiency

Awards

- National Metal Stamping Award for Excellence in Quality Control

- Safety Award for Zero Lost Time Incidents (multiple years)

- Employee of the Month Award for Outstanding Production Efficiency

Certificates

- Certified Metal Stamper (CMS)

- Certified Press Brake Operator (CPBO)

- Certified Punch Press Operator (CPPO)

- Certified Laser Cutting Operator (CLCO)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Metal Stamper

- Highlight your experience and skills in operating and maintaining a variety of stamping machines.

- Quantify your accomplishments with specific metrics whenever possible.

- Demonstrate your knowledge of lean manufacturing principles and how you have applied them to improve efficiency.

- Showcase your ability to collaborate with engineers and designers to troubleshoot and resolve stamping challenges.

- Emphasize your commitment to safety and your ability to maintain a clean and organized work environment.

Essential Experience Highlights for a Strong Metal Stamper Resume

- Set up and operate stamping machines to produce metal components according to specifications

- Inspect and maintain stamping dies and tooling to ensure optimal performance

- Monitor production processes and identify areas for improvement

- Collaborate with engineers and designers to develop and refine stamping processes

- Train and supervise new employees

- Adhere to safety protocols and maintain a clean and organized work environment

- Participate in continuous improvement initiatives to enhance productivity and quality

Frequently Asked Questions (FAQ’s) For Metal Stamper

What are the key skills required to be a successful Metal Stamper?

Successful Metal Stampers typically possess strong skills in die setting, metal forming, press brake operation, punch press operation, shear operation, and laser cutting.

What are the career prospects for Metal Stampers?

Metal Stampers with strong skills and experience can advance to positions such as Supervisor, Production Manager, or Quality Control Manager. Some may also choose to start their own metal stamping businesses.

What are the typical working conditions for Metal Stampers?

Metal Stampers typically work in manufacturing facilities, operating stamping machines and performing related tasks. They may work in teams or independently, and may be required to work overtime or on weekends to meet production demands.

What are the safety hazards associated with metal stamping?

Metal stamping involves working with heavy machinery and sharp tools, so safety is paramount. Common hazards include cuts, lacerations, and amputations. Metal Stampers must wear appropriate safety gear and follow established safety protocols to minimize the risk of injury.

What is the earning potential for Metal Stampers?

The earning potential for Metal Stampers varies depending on experience, skills, and location. According to the U.S. Bureau of Labor Statistics, the median annual salary for Metal Stampers was $46,720 in May 2021.

What are the educational requirements to become a Metal Stamper?

While there are no formal educational requirements to become a Metal Stamper, many employers prefer candidates with a high school diploma or equivalent. Some Metal Stampers may also choose to pursue additional training or certification programs to enhance their skills and knowledge.

What are the qualities of a successful Metal Stamper?

Successful Metal Stampers typically possess a strong attention to detail, mechanical aptitude, and problem-solving skills. They are also able to work independently and as part of a team, and are committed to safety and quality.