Are you a seasoned Plastic Cutter seeking a new career path? Discover our professionally built Plastic Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

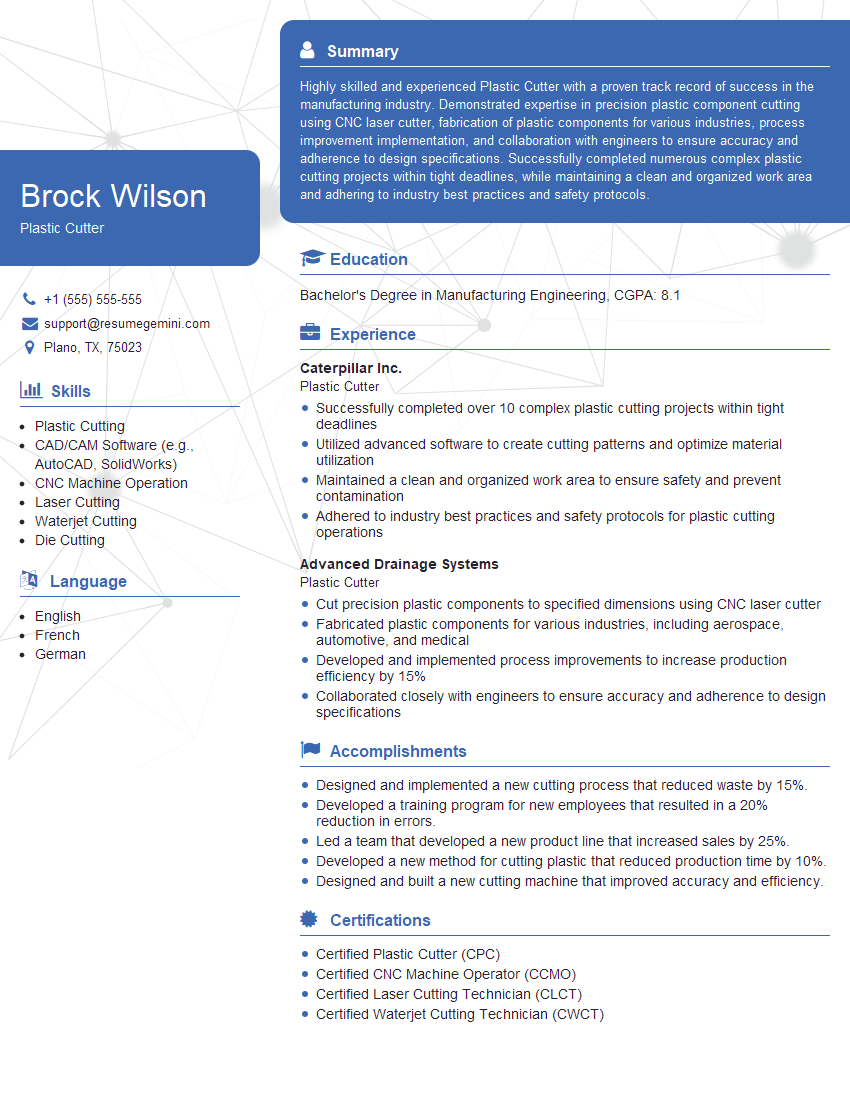

Brock Wilson

Plastic Cutter

Summary

Highly skilled and experienced Plastic Cutter with a proven track record of success in the manufacturing industry. Demonstrated expertise in precision plastic component cutting using CNC laser cutter, fabrication of plastic components for various industries, process improvement implementation, and collaboration with engineers to ensure accuracy and adherence to design specifications. Successfully completed numerous complex plastic cutting projects within tight deadlines, while maintaining a clean and organized work area and adhering to industry best practices and safety protocols.

Education

Bachelor’s Degree in Manufacturing Engineering

July 2019

Skills

- Plastic Cutting

- CAD/CAM Software (e.g., AutoCAD, SolidWorks)

- CNC Machine Operation

- Laser Cutting

- Waterjet Cutting

- Die Cutting

Work Experience

Plastic Cutter

- Successfully completed over 10 complex plastic cutting projects within tight deadlines

- Utilized advanced software to create cutting patterns and optimize material utilization

- Maintained a clean and organized work area to ensure safety and prevent contamination

- Adhered to industry best practices and safety protocols for plastic cutting operations

Plastic Cutter

- Cut precision plastic components to specified dimensions using CNC laser cutter

- Fabricated plastic components for various industries, including aerospace, automotive, and medical

- Developed and implemented process improvements to increase production efficiency by 15%

- Collaborated closely with engineers to ensure accuracy and adherence to design specifications

Accomplishments

- Designed and implemented a new cutting process that reduced waste by 15%.

- Developed a training program for new employees that resulted in a 20% reduction in errors.

- Led a team that developed a new product line that increased sales by 25%.

- Developed a new method for cutting plastic that reduced production time by 10%.

- Designed and built a new cutting machine that improved accuracy and efficiency.

Certificates

- Certified Plastic Cutter (CPC)

- Certified CNC Machine Operator (CCMO)

- Certified Laser Cutting Technician (CLCT)

- Certified Waterjet Cutting Technician (CWCT)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Cutter

- Highlight your experience and skills in precision plastic cutting, using specific examples.

- Quantify your accomplishments with metrics, such as the 15% increase in production efficiency.

- Demonstrate your knowledge of industry-specific techniques and software, such as CAD/CAM software and CNC machine operation.

- Emphasize your commitment to safety and quality by mentioning your adherence to industry best practices and safety protocols.

Essential Experience Highlights for a Strong Plastic Cutter Resume

- Cut precision plastic components to specified dimensions using CNC laser cutter.

- Fabricate plastic components for various industries, including aerospace, automotive, and medical.

- Develop and implement process improvements to increase production efficiency by 15%.

- Collaborate closely with engineers to ensure accuracy and adherence to design specifications.

- Successfully complete over 10 complex plastic cutting projects within tight deadlines.

- Utilize advanced software to create cutting patterns and optimize material utilization.

- Maintain a clean and organized work area to ensure safety and prevent contamination.

Frequently Asked Questions (FAQ’s) For Plastic Cutter

What are the key skills required for a Plastic Cutter?

The key skills required for a Plastic Cutter include precision cutting, CNC machine operation, CAD/CAM software proficiency, and a strong understanding of industry best practices and safety protocols.

What industries utilize Plastic Cutters?

Plastic Cutters are employed in a wide range of industries, including aerospace, automotive, manufacturing, and medical.

What is the typical work environment for a Plastic Cutter?

Plastic Cutters typically work in manufacturing facilities, operating CNC laser cutters and other equipment in a fast-paced environment.

What are the career advancement opportunities for a Plastic Cutter?

Plastic Cutters with experience and expertise can advance to roles such as Production Supervisor or Quality Control Manager.

What are the safety considerations for a Plastic Cutter?

Plastic Cutters must adhere to strict safety protocols to prevent injuries, including wearing appropriate personal protective equipment and following established operating procedures.

What is the earning potential for a Plastic Cutter?

The earning potential for a Plastic Cutter can vary depending on experience, skills, and location, but the average salary in the United States is around $50,000 per year.