Are you a seasoned Plastic Press Operator seeking a new career path? Discover our professionally built Plastic Press Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

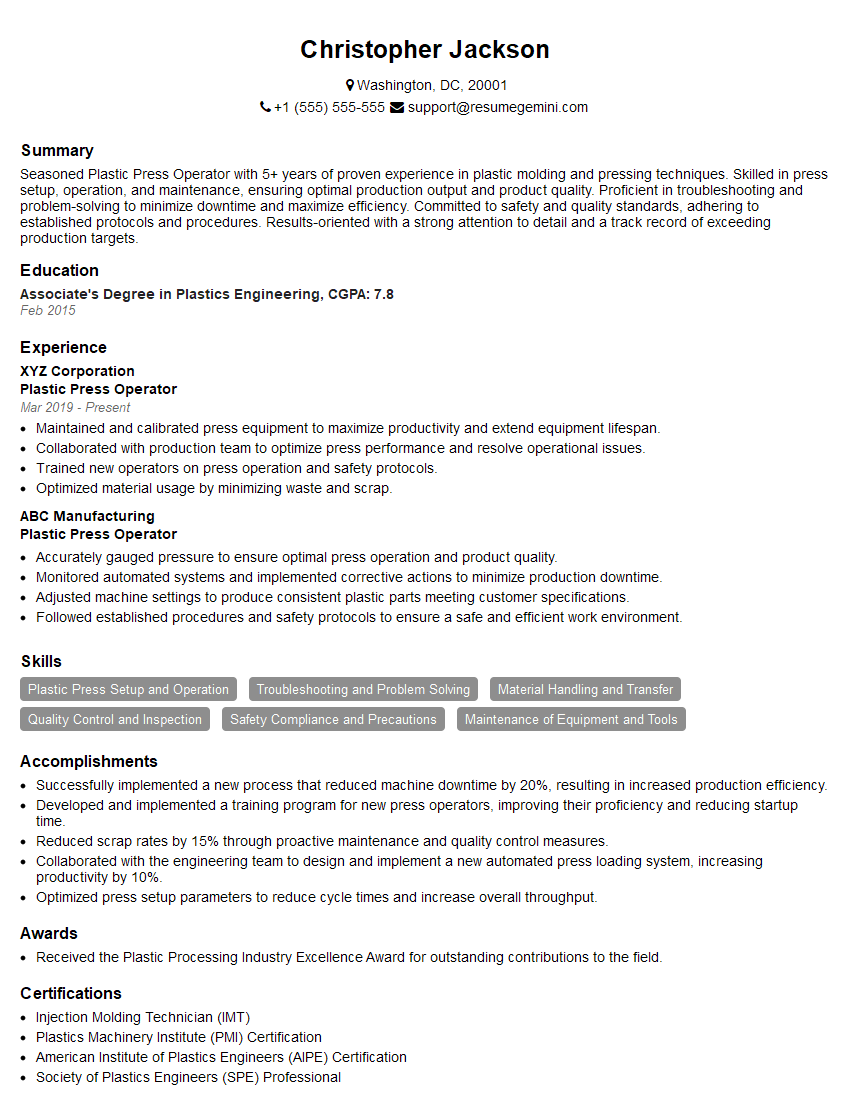

Christopher Jackson

Plastic Press Operator

Summary

Seasoned Plastic Press Operator with 5+ years of proven experience in plastic molding and pressing techniques. Skilled in press setup, operation, and maintenance, ensuring optimal production output and product quality. Proficient in troubleshooting and problem-solving to minimize downtime and maximize efficiency. Committed to safety and quality standards, adhering to established protocols and procedures. Results-oriented with a strong attention to detail and a track record of exceeding production targets.

Education

Associate’s Degree in Plastics Engineering

February 2015

Skills

- Plastic Press Setup and Operation

- Troubleshooting and Problem Solving

- Material Handling and Transfer

- Quality Control and Inspection

- Safety Compliance and Precautions

- Maintenance of Equipment and Tools

Work Experience

Plastic Press Operator

- Maintained and calibrated press equipment to maximize productivity and extend equipment lifespan.

- Collaborated with production team to optimize press performance and resolve operational issues.

- Trained new operators on press operation and safety protocols.

- Optimized material usage by minimizing waste and scrap.

Plastic Press Operator

- Accurately gauged pressure to ensure optimal press operation and product quality.

- Monitored automated systems and implemented corrective actions to minimize production downtime.

- Adjusted machine settings to produce consistent plastic parts meeting customer specifications.

- Followed established procedures and safety protocols to ensure a safe and efficient work environment.

Accomplishments

- Successfully implemented a new process that reduced machine downtime by 20%, resulting in increased production efficiency.

- Developed and implemented a training program for new press operators, improving their proficiency and reducing startup time.

- Reduced scrap rates by 15% through proactive maintenance and quality control measures.

- Collaborated with the engineering team to design and implement a new automated press loading system, increasing productivity by 10%.

- Optimized press setup parameters to reduce cycle times and increase overall throughput.

Awards

- Received the Plastic Processing Industry Excellence Award for outstanding contributions to the field.

Certificates

- Injection Molding Technician (IMT)

- Plastics Machinery Institute (PMI) Certification

- American Institute of Plastics Engineers (AIPE) Certification

- Society of Plastics Engineers (SPE) Professional

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Plastic Press Operator

- Highlight your technical expertise in press setup, operation, and maintenance.

- Quantify your accomplishments with specific metrics and results whenever possible.

- Showcase your ability to troubleshoot and solve problems efficiently.

- Emphasize your commitment to safety and quality by mentioning relevant certifications or awards.

Essential Experience Highlights for a Strong Plastic Press Operator Resume

- Accurately gauged pressure to ensure optimal press operation and product quality.

- Monitored automated systems and implemented corrective actions to minimize production downtime.

- Adjusted machine settings to produce consistent plastic parts meeting customer specifications.

- Collaborated with production team to optimize press performance and resolve operational issues.

- Trained new operators on press operation and safety protocols.

- Optimized material usage by minimizing waste and scrap.

- Maintained and calibrated press equipment to maximize productivity and extend equipment lifespan.

Frequently Asked Questions (FAQ’s) For Plastic Press Operator

What are the key skills required for a Plastic Press Operator?

Plastic Press Setup and Operation, Troubleshooting and Problem Solving, Material Handling and Transfer, Quality Control and Inspection, Safety Compliance and Precautions, Maintenance of Equipment and Tools.

What industries hire Plastic Press Operators?

Automotive, manufacturing, consumer goods, electronics, and medical device industries.

What are the career advancement opportunities for Plastic Press Operators?

Quality Control Inspector, Production Supervisor, Process Engineer, Plant Manager.

What is the average salary for a Plastic Press Operator?

Varies based on experience, location, and industry, but typically ranges from $18 to $25 per hour.

What is the work environment like for Plastic Press Operators?

Typically work in manufacturing facilities, operating and maintaining plastic presses in a loud and potentially hazardous environment.

Are there any certifications or licenses required for Plastic Press Operators?

Not typically required, but industry-recognized certifications, such as Certified Plastics Technician (CPT), can enhance job prospects.

What is the job outlook for Plastic Press Operators?

Projected to grow 6% from 2021 to 2031, faster than the average for all occupations.