Are you a seasoned Press Brake Operator seeking a new career path? Discover our professionally built Press Brake Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

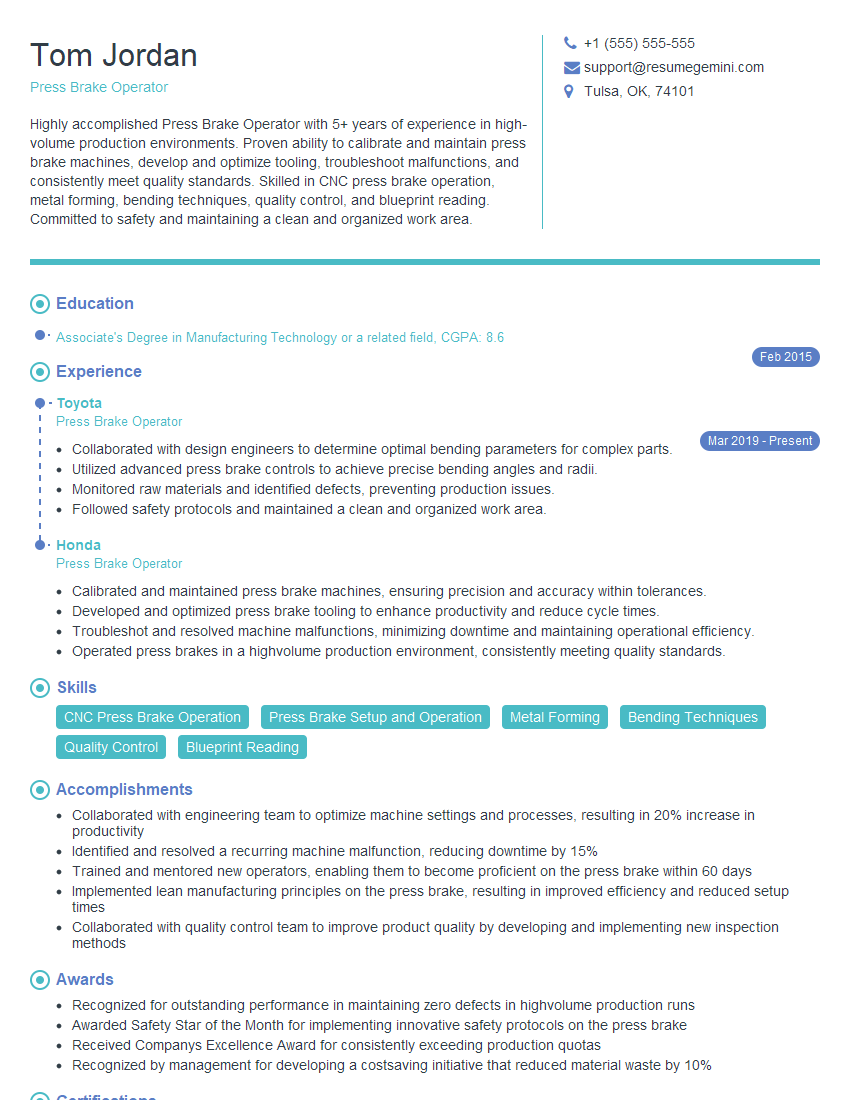

Tom Jordan

Press Brake Operator

Summary

Highly accomplished Press Brake Operator with 5+ years of experience in high-volume production environments. Proven ability to calibrate and maintain press brake machines, develop and optimize tooling, troubleshoot malfunctions, and consistently meet quality standards. Skilled in CNC press brake operation, metal forming, bending techniques, quality control, and blueprint reading. Committed to safety and maintaining a clean and organized work area.

Education

Associate’s Degree in Manufacturing Technology or a related field

February 2015

Skills

- CNC Press Brake Operation

- Press Brake Setup and Operation

- Metal Forming

- Bending Techniques

- Quality Control

- Blueprint Reading

Work Experience

Press Brake Operator

- Collaborated with design engineers to determine optimal bending parameters for complex parts.

- Utilized advanced press brake controls to achieve precise bending angles and radii.

- Monitored raw materials and identified defects, preventing production issues.

- Followed safety protocols and maintained a clean and organized work area.

Press Brake Operator

- Calibrated and maintained press brake machines, ensuring precision and accuracy within tolerances.

- Developed and optimized press brake tooling to enhance productivity and reduce cycle times.

- Troubleshot and resolved machine malfunctions, minimizing downtime and maintaining operational efficiency.

- Operated press brakes in a highvolume production environment, consistently meeting quality standards.

Accomplishments

- Collaborated with engineering team to optimize machine settings and processes, resulting in 20% increase in productivity

- Identified and resolved a recurring machine malfunction, reducing downtime by 15%

- Trained and mentored new operators, enabling them to become proficient on the press brake within 60 days

- Implemented lean manufacturing principles on the press brake, resulting in improved efficiency and reduced setup times

- Collaborated with quality control team to improve product quality by developing and implementing new inspection methods

Awards

- Recognized for outstanding performance in maintaining zero defects in highvolume production runs

- Awarded Safety Star of the Month for implementing innovative safety protocols on the press brake

- Received Companys Excellence Award for consistently exceeding production quotas

- Recognized by management for developing a costsaving initiative that reduced material waste by 10%

Certificates

- Certified Press Brake Operator (CPBO)

- Certified Metal Fabricator (CMF)

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Press Brake Operator

- Highlight your experience in operating and maintaining press brake machines.

- Showcase your skills in developing and optimizing tooling to improve productivity.

- Emphasize your ability to troubleshoot and resolve machine malfunctions.

- Quantify your accomplishments with specific metrics, such as reduced downtime or increased production output.

- Demonstrate your understanding of quality control processes and adherence to safety protocols.

Essential Experience Highlights for a Strong Press Brake Operator Resume

- Calibrating and maintaining press brake machines to ensure precision and accuracy within tolerances

- Developing and optimizing press brake tooling to enhance productivity and reduce cycle times

- Troubleshooting and resolving machine malfunctions, minimizing downtime and maintaining operational efficiency

- Operating press brakes in a high-volume production environment, consistently meeting quality standards

- Collaborating with design engineers to determine optimal bending parameters for complex parts

- Utilizing advanced press brake controls to achieve precise bending angles and radii

- Monitoring raw materials and identifying defects, preventing production issues

Frequently Asked Questions (FAQ’s) For Press Brake Operator

What are the primary duties of a Press Brake Operator?

The primary duties of a Press Brake Operator include calibrating and maintaining press brake machines, developing and optimizing tooling, troubleshooting malfunctions, operating press brakes in a high-volume production environment, and ensuring quality standards are met.

What skills are required to be a successful Press Brake Operator?

To be a successful Press Brake Operator, you will need skills in CNC press brake operation, press brake setup and operation, metal forming, bending techniques, quality control, and blueprint reading.

What industries employ Press Brake Operators?

Press Brake Operators are employed in a variety of industries, including automotive, aerospace, manufacturing, and construction.

What is the average salary for a Press Brake Operator?

The average salary for a Press Brake Operator in the United States is around $45,000 per year.

What are the career prospects for a Press Brake Operator?

Press Brake Operators can advance their careers by becoming supervisors, quality control inspectors, or machine programmers.

What is the work environment like for a Press Brake Operator?

Press Brake Operators typically work in a manufacturing environment, which can be noisy and have potential hazards. They may also work overtime or on weekends to meet production demands.