Are you a seasoned Steel Cutter seeking a new career path? Discover our professionally built Steel Cutter Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

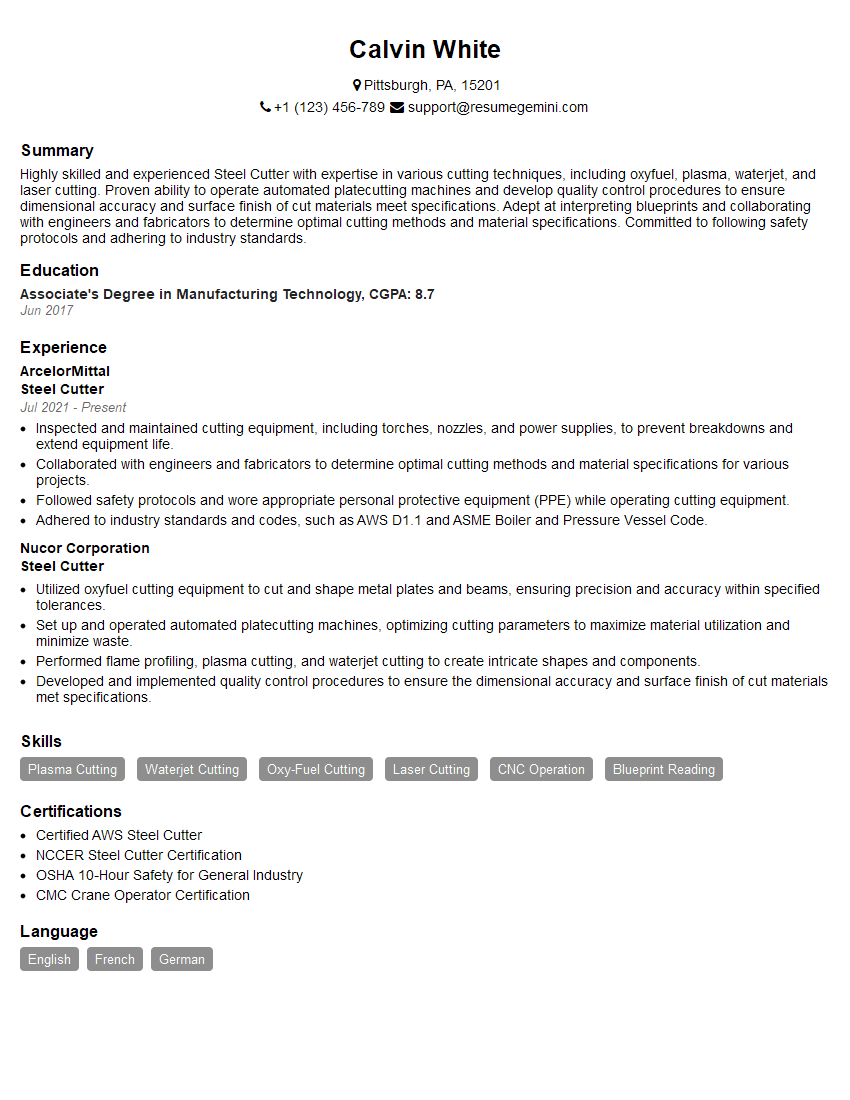

Calvin White

Steel Cutter

Summary

Highly skilled and experienced Steel Cutter with expertise in various cutting techniques, including oxyfuel, plasma, waterjet, and laser cutting. Proven ability to operate automated platecutting machines and develop quality control procedures to ensure dimensional accuracy and surface finish of cut materials meet specifications. Adept at interpreting blueprints and collaborating with engineers and fabricators to determine optimal cutting methods and material specifications. Committed to following safety protocols and adhering to industry standards.

Education

Associate’s Degree in Manufacturing Technology

June 2017

Skills

- Plasma Cutting

- Waterjet Cutting

- Oxy-Fuel Cutting

- Laser Cutting

- CNC Operation

- Blueprint Reading

Work Experience

Steel Cutter

- Inspected and maintained cutting equipment, including torches, nozzles, and power supplies, to prevent breakdowns and extend equipment life.

- Collaborated with engineers and fabricators to determine optimal cutting methods and material specifications for various projects.

- Followed safety protocols and wore appropriate personal protective equipment (PPE) while operating cutting equipment.

- Adhered to industry standards and codes, such as AWS D1.1 and ASME Boiler and Pressure Vessel Code.

Steel Cutter

- Utilized oxyfuel cutting equipment to cut and shape metal plates and beams, ensuring precision and accuracy within specified tolerances.

- Set up and operated automated platecutting machines, optimizing cutting parameters to maximize material utilization and minimize waste.

- Performed flame profiling, plasma cutting, and waterjet cutting to create intricate shapes and components.

- Developed and implemented quality control procedures to ensure the dimensional accuracy and surface finish of cut materials met specifications.

Certificates

- Certified AWS Steel Cutter

- NCCER Steel Cutter Certification

- OSHA 10-Hour Safety for General Industry

- CMC Crane Operator Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Steel Cutter

- Showcase your technical skills and experience in various cutting techniques in your resume.

- Provide specific examples of projects where you successfully applied your cutting expertise.

- Highlight your ability to read and interpret blueprints and collaborate with other professionals.

- Demonstrate your commitment to safety and industry standards.

Essential Experience Highlights for a Strong Steel Cutter Resume

- Utilized oxyfuel cutting equipment to cut and shape metal plates and beams, ensuring precision and accuracy within specified tolerances.

- Set up and operated automated platecutting machines, optimizing cutting parameters to maximize material utilization and minimize waste.

- Performed flame profiling, plasma cutting, and waterjet cutting to create intricate shapes and components.

- Developed and implemented quality control procedures to ensure the dimensional accuracy and surface finish of cut materials met specifications.

- Inspected and maintained cutting equipment, including torches, nozzles, and power supplies, to prevent breakdowns and extend equipment life.

- Collaborated with engineers and fabricators to determine optimal cutting methods and material specifications for various projects.

- Followed safety protocols and wore appropriate personal protective equipment (PPE) while operating cutting equipment.

Frequently Asked Questions (FAQ’s) For Steel Cutter

What are the primary responsibilities of a Steel Cutter?

Steel Cutters are responsible for cutting and shaping metal plates and beams using various techniques such as oxyfuel, plasma, waterjet, and laser cutting. They set up and operate automated platecutting machines, develop quality control procedures, and collaborate with engineers and fabricators.

What skills are required to be a successful Steel Cutter?

Steel Cutters require a combination of technical skills, including proficiency in oxyfuel cutting, plasma cutting, and waterjet cutting. They should also have a good understanding of blueprint reading, quality control procedures, and safety protocols.

What is the job outlook for Steel Cutters?

The job outlook for Steel Cutters is expected to be stable in the coming years due to the continued demand for metal fabrication in industries such as construction, manufacturing, and shipbuilding.

What are the career advancement opportunities for Steel Cutters?

Steel Cutters can advance their careers by becoming supervisors or managers in metal fabrication shops. They can also specialize in specific cutting techniques, such as laser cutting or waterjet cutting.

What is the average salary for Steel Cutters?

The average salary for Steel Cutters varies depending on their experience, skills, and location. However, according to the U.S. Bureau of Labor Statistics, the median annual salary for Structural Metal Fabricators and Fitters, a related occupation, was $47,160 in May 2021.

What are the working conditions like for Steel Cutters?

Steel Cutters typically work in metal fabrication shops or industrial settings. They may work with heavy machinery and sharp tools, so it is important to follow safety protocols and wear appropriate personal protective equipment.