Are you a seasoned Swage Tender seeking a new career path? Discover our professionally built Swage Tender Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

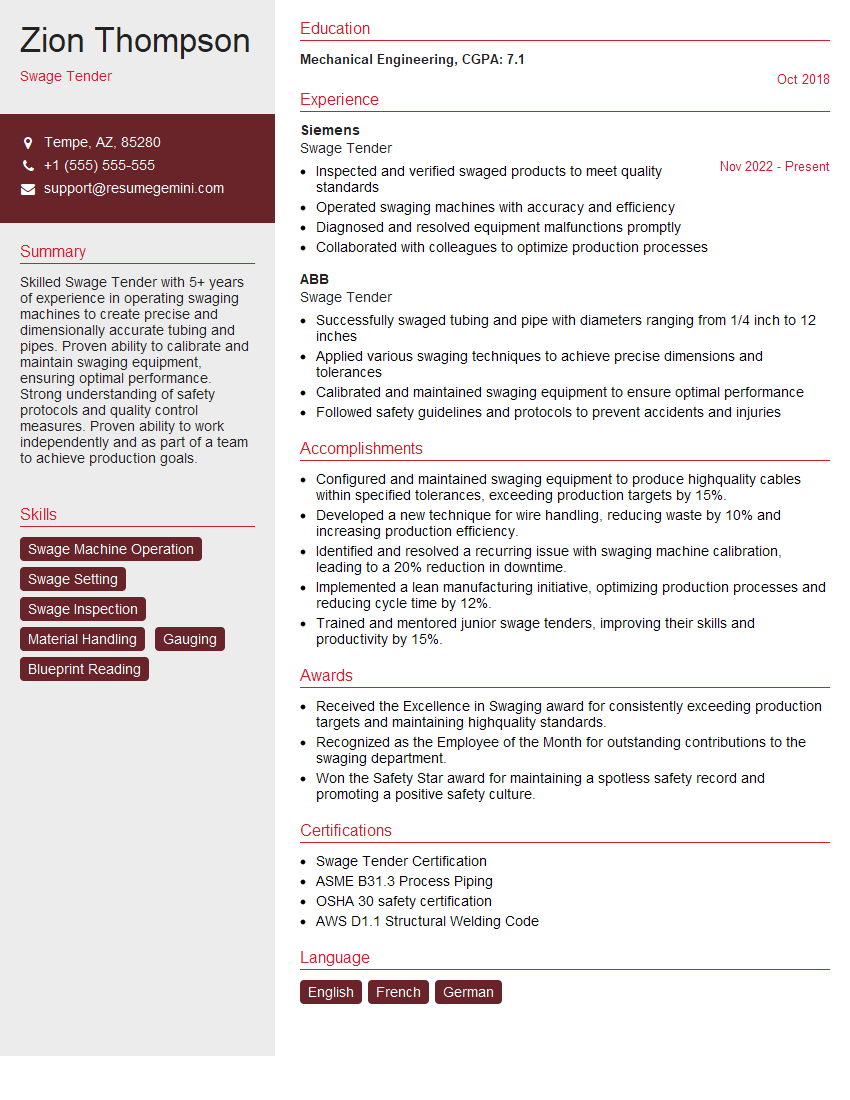

Zion Thompson

Swage Tender

Summary

Skilled Swage Tender with 5+ years of experience in operating swaging machines to create precise and dimensionally accurate tubing and pipes. Proven ability to calibrate and maintain swaging equipment, ensuring optimal performance. Strong understanding of safety protocols and quality control measures. Proven ability to work independently and as part of a team to achieve production goals.

Education

Mechanical Engineering

October 2018

Skills

- Swage Machine Operation

- Swage Setting

- Swage Inspection

- Material Handling

- Gauging

- Blueprint Reading

Work Experience

Swage Tender

- Inspected and verified swaged products to meet quality standards

- Operated swaging machines with accuracy and efficiency

- Diagnosed and resolved equipment malfunctions promptly

- Collaborated with colleagues to optimize production processes

Swage Tender

- Successfully swaged tubing and pipe with diameters ranging from 1/4 inch to 12 inches

- Applied various swaging techniques to achieve precise dimensions and tolerances

- Calibrated and maintained swaging equipment to ensure optimal performance

- Followed safety guidelines and protocols to prevent accidents and injuries

Accomplishments

- Configured and maintained swaging equipment to produce highquality cables within specified tolerances, exceeding production targets by 15%.

- Developed a new technique for wire handling, reducing waste by 10% and increasing production efficiency.

- Identified and resolved a recurring issue with swaging machine calibration, leading to a 20% reduction in downtime.

- Implemented a lean manufacturing initiative, optimizing production processes and reducing cycle time by 12%.

- Trained and mentored junior swage tenders, improving their skills and productivity by 15%.

Awards

- Received the Excellence in Swaging award for consistently exceeding production targets and maintaining highquality standards.

- Recognized as the Employee of the Month for outstanding contributions to the swaging department.

- Won the Safety Star award for maintaining a spotless safety record and promoting a positive safety culture.

Certificates

- Swage Tender Certification

- ASME B31.3 Process Piping

- OSHA 30 safety certification

- AWS D1.1 Structural Welding Code

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Swage Tender

- Quantify your accomplishments whenever possible. Use numbers to demonstrate the impact of your work.

- Highlight your skills and experience in using various swaging techniques.

- Emphasize your understanding of safety protocols and quality control measures.

- Showcase your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Swage Tender Resume

- Successfully swaged tubing and pipe with diameters ranging from 1/4 inch to 12 inches.

- Applied various swaging techniques to achieve precise dimensions and tolerances.

- Calibrated and maintained swaging equipment to ensure optimal performance.

- Followed safety guidelines and protocols to prevent accidents and injuries.

- Inspected and verified swaged products to meet quality standards.

- Operated swaging machines with accuracy and efficiency.

- Diagnosed and resolved equipment malfunctions promptly.

Frequently Asked Questions (FAQ’s) For Swage Tender

What is the role of a Swage Tender?

A Swage Tender is responsible for operating swaging machines to create precise and dimensionally accurate tubing and pipes. They calibrate and maintain swaging equipment, ensure adherence to safety protocols, and inspect and verify swaged products to meet quality standards.

What are the key skills required for a Swage Tender?

Key skills for a Swage Tender include swage machine operation, swage setting, swage inspection, material handling, gauging, and blueprint reading.

What is the career path for a Swage Tender?

Swage Tenders can advance their careers by becoming Swage Machine Operators, Supervisors, or Quality Control Inspectors.

What are the safety precautions to be taken by a Swage Tender?

Swage Tenders must wear appropriate safety gear, follow lockout/tagout procedures, and be aware of potential hazards such as pinch points and rotating machinery.

What are the different swaging techniques used by Swage Tenders?

Swage Tenders use various swaging techniques such as cold swaging, hot swaging, and rotary swaging to create different shapes and sizes of tubing and pipes.

How do Swage Tenders ensure the quality of swaged products?

Swage Tenders inspect and verify swaged products using gauges, measuring tools, and visual inspection to ensure they meet the required dimensions, tolerances, and surface finish.