Are you a seasoned Wire Coiner seeking a new career path? Discover our professionally built Wire Coiner Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

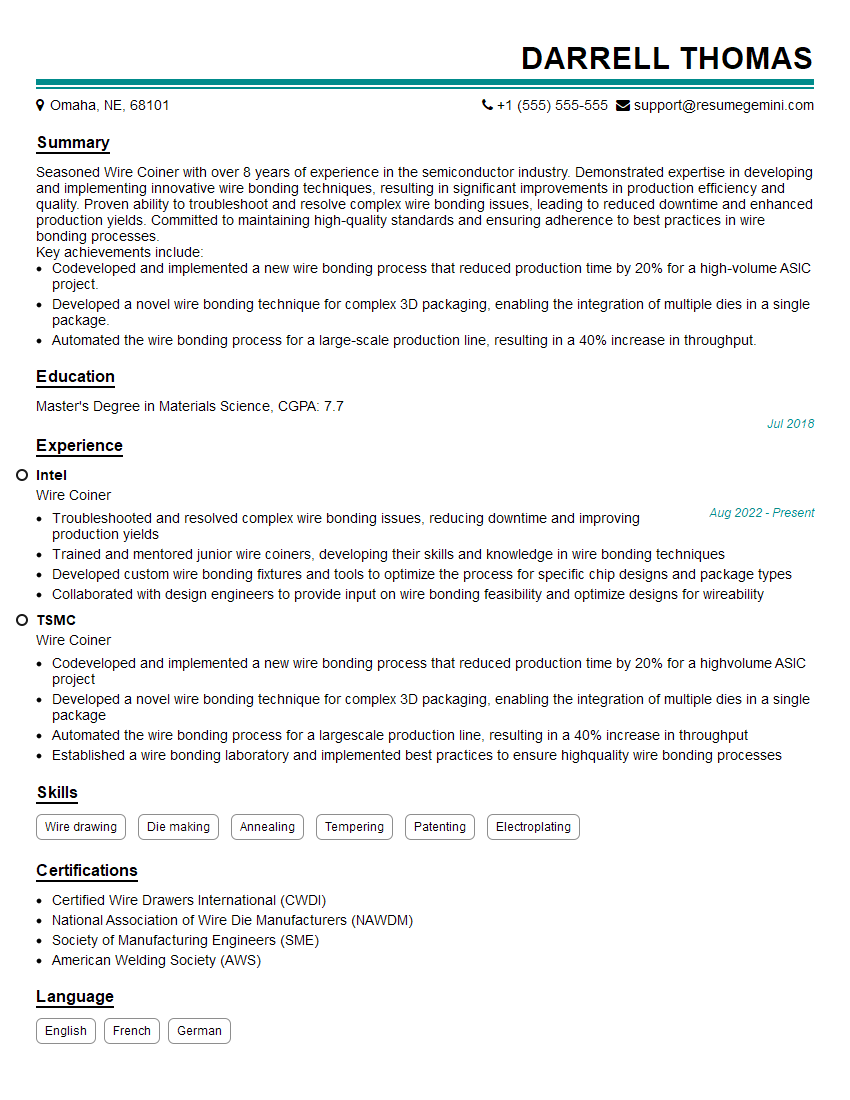

Darrell Thomas

Wire Coiner

Summary

Seasoned Wire Coiner with over 8 years of experience in the semiconductor industry. Demonstrated expertise in developing and implementing innovative wire bonding techniques, resulting in significant improvements in production efficiency and quality. Proven ability to troubleshoot and resolve complex wire bonding issues, leading to reduced downtime and enhanced production yields. Committed to maintaining high-quality standards and ensuring adherence to best practices in wire bonding processes.

Key achievements include:

- Codeveloped and implemented a new wire bonding process that reduced production time by 20% for a high-volume ASIC project.

- Developed a novel wire bonding technique for complex 3D packaging, enabling the integration of multiple dies in a single package.

- Automated the wire bonding process for a large-scale production line, resulting in a 40% increase in throughput.

Education

Master’s Degree in Materials Science

July 2018

Skills

- Wire drawing

- Die making

- Annealing

- Tempering

- Patenting

- Electroplating

Work Experience

Wire Coiner

- Troubleshooted and resolved complex wire bonding issues, reducing downtime and improving production yields

- Trained and mentored junior wire coiners, developing their skills and knowledge in wire bonding techniques

- Developed custom wire bonding fixtures and tools to optimize the process for specific chip designs and package types

- Collaborated with design engineers to provide input on wire bonding feasibility and optimize designs for wireability

Wire Coiner

- Codeveloped and implemented a new wire bonding process that reduced production time by 20% for a highvolume ASIC project

- Developed a novel wire bonding technique for complex 3D packaging, enabling the integration of multiple dies in a single package

- Automated the wire bonding process for a largescale production line, resulting in a 40% increase in throughput

- Established a wire bonding laboratory and implemented best practices to ensure highquality wire bonding processes

Certificates

- Certified Wire Drawers International (CWDI)

- National Association of Wire Die Manufacturers (NAWDM)

- Society of Manufacturing Engineers (SME)

- American Welding Society (AWS)

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Wire Coiner

- Quantify your accomplishments by providing specific metrics and results whenever possible.

- Highlight your expertise in different wire bonding techniques and processes, such as die bonding, ball bonding, and wedge bonding.

- Showcase your understanding of wire bonding materials, equipment, and industry standards.

- Emphasize your ability to work independently and as part of a team in a fast-paced production environment.

- Include keywords related to the wire bonding industry, such as ‘wire bonding’, ‘semiconductor packaging’, and ‘microelectronics’.

Essential Experience Highlights for a Strong Wire Coiner Resume

- Develop and implement new wire bonding processes to improve production efficiency and quality.

- Troubleshoot and resolve complex wire bonding issues to minimize downtime and improve production yields.

- Establish and maintain a wire bonding laboratory to ensure adherence to best practices and high-quality standards.

- Train and mentor junior wire coiners to develop their skills and knowledge in wire bonding techniques.

- Collaborate with design engineers to provide input on wire bonding feasibility and optimize designs for wireability.

- Develop custom wire bonding fixtures and tools to optimize the process for specific chip designs and package types.

Frequently Asked Questions (FAQ’s) For Wire Coiner

What is wire coining?

Wire coining is a metalworking process that uses a die to create a raised or recessed design on a metal surface. It is often used to create decorative patterns on jewelry, coins, and other metal objects.

What are the different types of wire coining?

There are two main types of wire coining: hand coining and machine coining. Hand coining is done using a hammer and a die, while machine coining is done using a press.

What are the advantages of wire coining?

Wire coining offers several advantages over other metalworking processes, including: high precision, repeatability, and durability. It can also be used to create complex designs that would be difficult or impossible to produce using other methods.

What are the applications of wire coining?

Wire coining is used in a wide variety of applications, including: jewelry making, coin making, and metalworking. It can also be used to create decorative patterns on a variety of other metal objects, such as furniture, picture frames, and even buildings.

What are the challenges of wire coining?

Wire coining can be a challenging process, especially when creating complex designs. It requires a high level of skill and precision to produce high-quality results. Additionally, the dies used in wire coining can be expensive, which can limit its use for small-scale projects.

What are the future trends in wire coining?

The future of wire coining is bright. As technology continues to develop, new and innovative ways to use wire coining are being discovered. For example, wire coining is being used to create 3D objects, such as jewelry and sculptures.