Are you a seasoned Automatic Driller and Reamer seeking a new career path? Discover our professionally built Automatic Driller and Reamer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

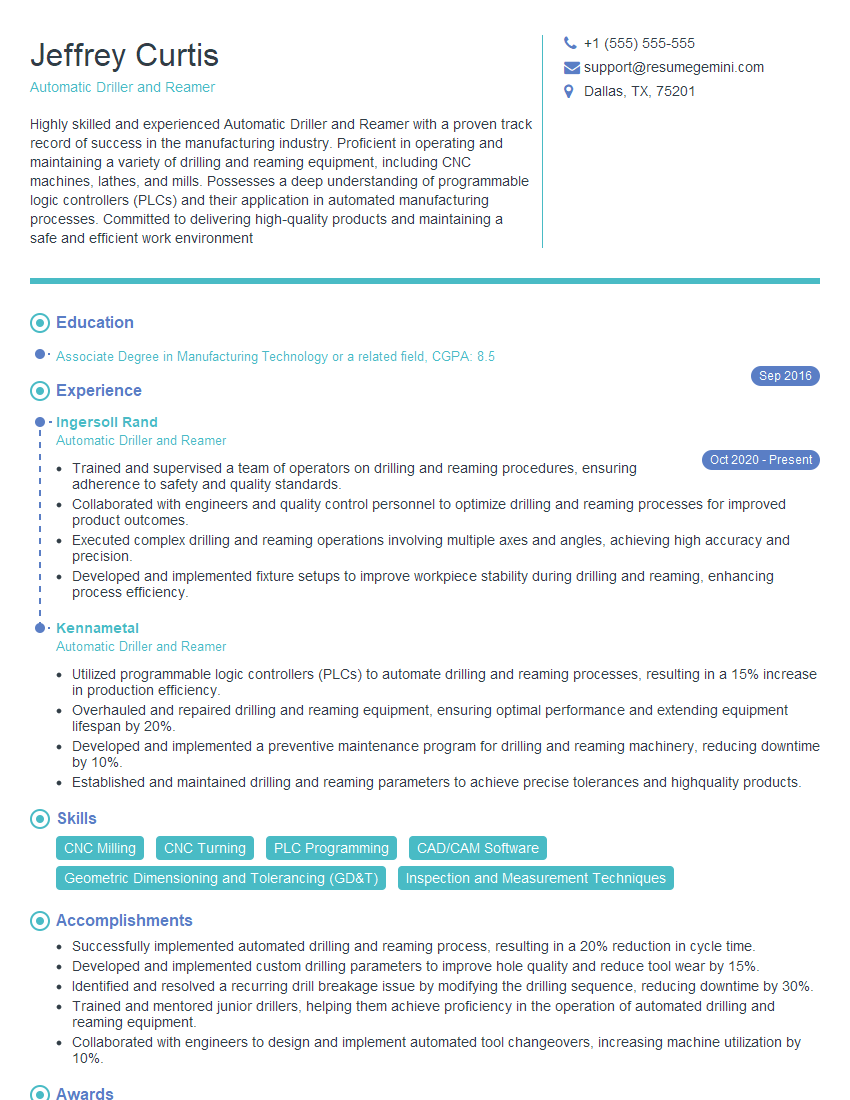

Jeffrey Curtis

Automatic Driller and Reamer

Summary

Highly skilled and experienced Automatic Driller and Reamer with a proven track record of success in the manufacturing industry. Proficient in operating and maintaining a variety of drilling and reaming equipment, including CNC machines, lathes, and mills. Possesses a deep understanding of programmable logic controllers (PLCs) and their application in automated manufacturing processes. Committed to delivering high-quality products and maintaining a safe and efficient work environment

Education

Associate Degree in Manufacturing Technology or a related field

September 2016

Skills

- CNC Milling

- CNC Turning

- PLC Programming

- CAD/CAM Software

- Geometric Dimensioning and Tolerancing (GD&T)

- Inspection and Measurement Techniques

Work Experience

Automatic Driller and Reamer

- Trained and supervised a team of operators on drilling and reaming procedures, ensuring adherence to safety and quality standards.

- Collaborated with engineers and quality control personnel to optimize drilling and reaming processes for improved product outcomes.

- Executed complex drilling and reaming operations involving multiple axes and angles, achieving high accuracy and precision.

- Developed and implemented fixture setups to improve workpiece stability during drilling and reaming, enhancing process efficiency.

Automatic Driller and Reamer

- Utilized programmable logic controllers (PLCs) to automate drilling and reaming processes, resulting in a 15% increase in production efficiency.

- Overhauled and repaired drilling and reaming equipment, ensuring optimal performance and extending equipment lifespan by 20%.

- Developed and implemented a preventive maintenance program for drilling and reaming machinery, reducing downtime by 10%.

- Established and maintained drilling and reaming parameters to achieve precise tolerances and highquality products.

Accomplishments

- Successfully implemented automated drilling and reaming process, resulting in a 20% reduction in cycle time.

- Developed and implemented custom drilling parameters to improve hole quality and reduce tool wear by 15%.

- Identified and resolved a recurring drill breakage issue by modifying the drilling sequence, reducing downtime by 30%.

- Trained and mentored junior drillers, helping them achieve proficiency in the operation of automated drilling and reaming equipment.

- Collaborated with engineers to design and implement automated tool changeovers, increasing machine utilization by 10%.

Awards

- Received the Employee of the Month award for exceptional performance and dedication to the drilling and reaming department.

- Recognized for outstanding contributions to the implementation of automated drilling and reaming processes.

- Awarded a safety commendation for adhering to strict safety protocols and maintaining a safe work environment.

Certificates

- Certified Manufacturing Engineer (CMfgE)

- Certified Quality Engineer (CQE)

- Certified Production Technician (CPT)

- ISO 9001:2015 Auditor

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Automatic Driller and Reamer

- Highlight your proficiency in operating and maintaining drilling and reaming equipment, including CNC machines, lathes, and mills.

- Showcase your skills in programming and operating programmable logic controllers (PLCs) for automated manufacturing processes

- Emphasize your experience in developing and implementing preventive maintenance programs to ensure optimal equipment performance and lifespan

- Demonstrate your commitment to delivering high-quality products and maintaining a safe and efficient work environment

Essential Experience Highlights for a Strong Automatic Driller and Reamer Resume

- Operate and maintain drilling and reaming equipment, including CNC machines, lathes, and mills

- Program and operate programmable logic controllers (PLCs) to automate drilling and reaming processes

- Develop and implement preventive maintenance programs to ensure optimal equipment performance and lifespan

- Inspect and measure workpieces to ensure adherence to specified tolerances and quality standards

- Train and supervise a team of operators on drilling and reaming procedures and safety protocols

- Collaborate with engineers and quality control personnel to optimize drilling and reaming processes

- Troubleshoot and resolve complex technical issues related to drilling and reaming operations

Frequently Asked Questions (FAQ’s) For Automatic Driller and Reamer

What is the primary role of an Automatic Driller and Reamer?

The primary role of an Automatic Driller and Reamer is to operate and maintain drilling and reaming equipment, including CNC machines, lathes, and mills to produce high-quality parts and components

What skills and qualifications are required to become an Automatic Driller and Reamer?

To become an Automatic Driller and Reamer, you typically need an associate degree in manufacturing technology or a related field, as well as proficiency in operating and maintaining CNC machines, lathes, and mills, programming PLCs, and implementing preventive maintenance programs

What is the job outlook for Automatic Drillers and Reamers?

The job outlook for Automatic Drillers and Reamers is expected to grow in the coming years due to the increasing demand for automated manufacturing processes in various industries, such as automotive, aerospace, and medical

What are the key responsibilities of an Automatic Driller and Reamer?

Key responsibilities of an Automatic Driller and Reamer include operating and maintaining drilling and reaming equipment, programming PLCs, developing preventive maintenance programs, inspecting and measuring workpieces, and collaborating with engineers and quality control personnel

What are the key skills and qualities of a successful Automatic Driller and Reamer?

Successful Automatic Drillers and Reamers possess a strong mechanical aptitude, attention to detail, problem-solving skills, and a commitment to safety and quality