Are you a seasoned Bore Mill Operator for Plastic seeking a new career path? Discover our professionally built Bore Mill Operator for Plastic Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

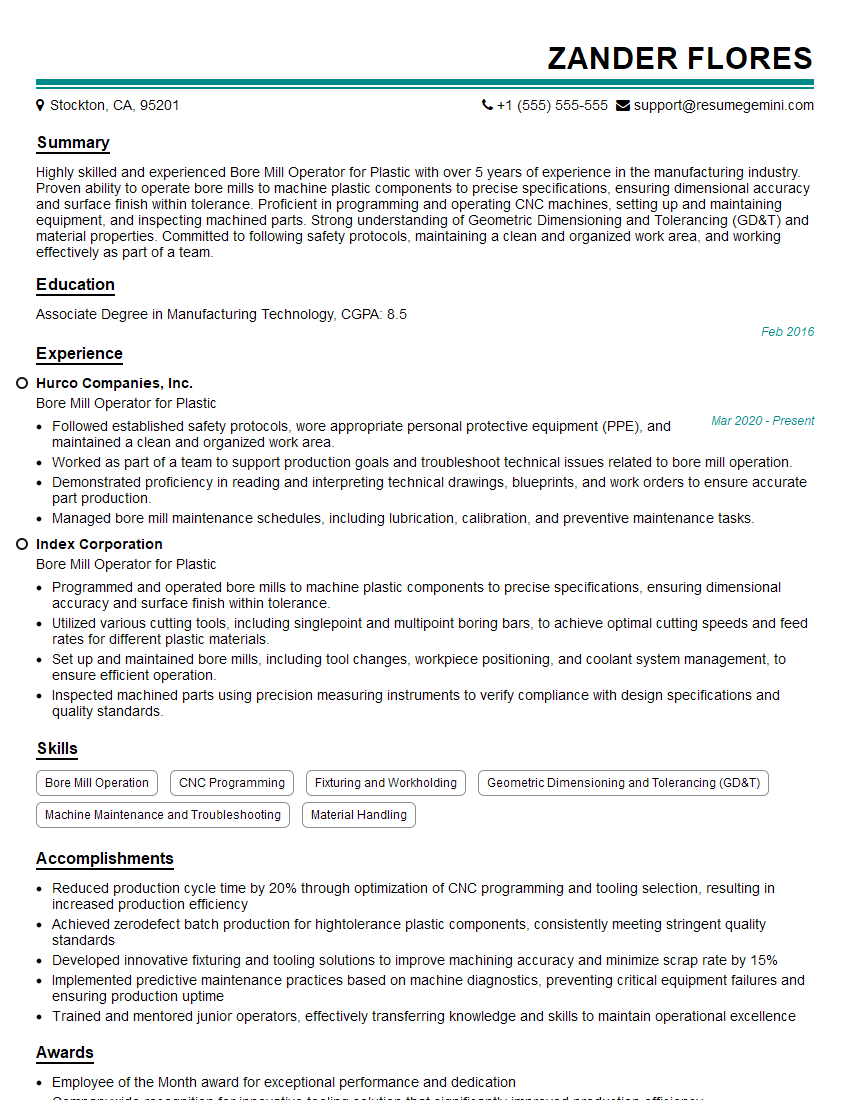

Zander Flores

Bore Mill Operator for Plastic

Summary

Highly skilled and experienced Bore Mill Operator for Plastic with over 5 years of experience in the manufacturing industry. Proven ability to operate bore mills to machine plastic components to precise specifications, ensuring dimensional accuracy and surface finish within tolerance. Proficient in programming and operating CNC machines, setting up and maintaining equipment, and inspecting machined parts. Strong understanding of Geometric Dimensioning and Tolerancing (GD&T) and material properties. Committed to following safety protocols, maintaining a clean and organized work area, and working effectively as part of a team.

Education

Associate Degree in Manufacturing Technology

February 2016

Skills

- Bore Mill Operation

- CNC Programming

- Fixturing and Workholding

- Geometric Dimensioning and Tolerancing (GD&T)

- Machine Maintenance and Troubleshooting

- Material Handling

Work Experience

Bore Mill Operator for Plastic

- Followed established safety protocols, wore appropriate personal protective equipment (PPE), and maintained a clean and organized work area.

- Worked as part of a team to support production goals and troubleshoot technical issues related to bore mill operation.

- Demonstrated proficiency in reading and interpreting technical drawings, blueprints, and work orders to ensure accurate part production.

- Managed bore mill maintenance schedules, including lubrication, calibration, and preventive maintenance tasks.

Bore Mill Operator for Plastic

- Programmed and operated bore mills to machine plastic components to precise specifications, ensuring dimensional accuracy and surface finish within tolerance.

- Utilized various cutting tools, including singlepoint and multipoint boring bars, to achieve optimal cutting speeds and feed rates for different plastic materials.

- Set up and maintained bore mills, including tool changes, workpiece positioning, and coolant system management, to ensure efficient operation.

- Inspected machined parts using precision measuring instruments to verify compliance with design specifications and quality standards.

Accomplishments

- Reduced production cycle time by 20% through optimization of CNC programming and tooling selection, resulting in increased production efficiency

- Achieved zerodefect batch production for hightolerance plastic components, consistently meeting stringent quality standards

- Developed innovative fixturing and tooling solutions to improve machining accuracy and minimize scrap rate by 15%

- Implemented predictive maintenance practices based on machine diagnostics, preventing critical equipment failures and ensuring production uptime

- Trained and mentored junior operators, effectively transferring knowledge and skills to maintain operational excellence

Awards

- Employee of the Month award for exceptional performance and dedication

- Companywide recognition for innovative tooling solution that significantly improved production efficiency

- Industry Award for contribution to the advancement of bore milling technology in the plastic industry

Certificates

- Certified Bore Mill Operator for Plastic

- Certified Manufacturing Technologist (CMfgT)

- Certified Quality Technician (CQT)

- Certified Six Sigma Black Belt

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Bore Mill Operator for Plastic

- Highlight your experience and skills in operating bore mills and machining plastic components.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Emphasize your understanding of GD&T and material properties, as these are essential for success in this role.

- Showcase your ability to work independently and as part of a team, as well as your commitment to safety and quality.

Essential Experience Highlights for a Strong Bore Mill Operator for Plastic Resume

- Programmed and operated bore mills to machine plastic components to precise specifications, ensuring dimensional accuracy and surface finish within tolerance.

- Utilized various cutting tools, including singlepoint and multipoint boring bars, to achieve optimal cutting speeds and feed rates for different plastic materials.

- Set up and maintained bore mills, including tool changes, workpiece positioning, and coolant system management, to ensure efficient operation.

- Inspected machined parts using precision measuring instruments to verify compliance with design specifications and quality standards.

- Managed bore mill maintenance schedules, including lubrication, calibration, and preventive maintenance tasks.

- Worked as part of a team to support production goals, troubleshoot technical issues, and improve processes.

- Demonstrated proficiency in reading and interpreting technical drawings, blueprints, and work orders to ensure accurate part production.

Frequently Asked Questions (FAQ’s) For Bore Mill Operator for Plastic

What is the primary responsibility of a Bore Mill Operator for Plastic?

The primary responsibility of a Bore Mill Operator for Plastic is to operate bore mills to machine plastic components to precise specifications, ensuring dimensional accuracy and surface finish within tolerance.

What are the essential skills required for a Bore Mill Operator for Plastic?

Essential skills for a Bore Mill Operator for Plastic include: bore mill operation, CNC programming, fixturing and workholding, Geometric Dimensioning and Tolerancing (GD&T), machine maintenance and troubleshooting, and material handling.

What is the educational background required for a Bore Mill Operator for Plastic?

While a high school diploma or equivalent is typically the minimum educational requirement for a Bore Mill Operator for Plastic, many employers prefer candidates with an associate degree or certification in a related field, such as manufacturing technology.

What are the career opportunities for a Bore Mill Operator for Plastic?

Bore Mill Operators for Plastic can advance their careers by becoming CNC programmers, supervisors, or quality control inspectors. They may also specialize in machining specific types of plastics or components.

Is experience necessary for a Bore Mill Operator for Plastic?

While not always required, experience in bore mill operation, CNC programming, or a related field is highly preferred for Bore Mill Operators for Plastic. This experience can be gained through formal training programs, apprenticeships, or on-the-job training.

What is the work environment like for a Bore Mill Operator for Plastic?

Bore Mill Operators for Plastic typically work in manufacturing facilities, operating bore mills and other equipment in a fast-paced, production-oriented environment. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production demands.