Are you a seasoned Chamfering Machine Operator seeking a new career path? Discover our professionally built Chamfering Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

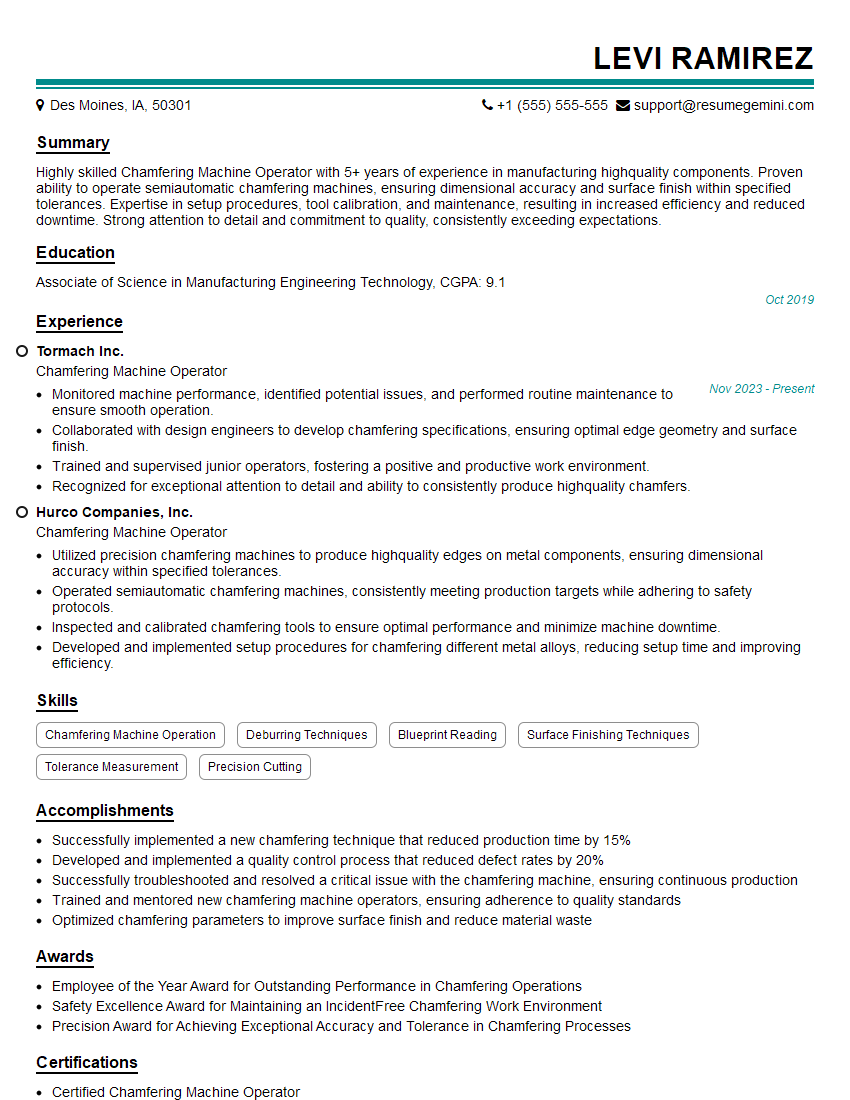

Levi Ramirez

Chamfering Machine Operator

Summary

Highly skilled Chamfering Machine Operator with 5+ years of experience in manufacturing highquality components. Proven ability to operate semiautomatic chamfering machines, ensuring dimensional accuracy and surface finish within specified tolerances. Expertise in setup procedures, tool calibration, and maintenance, resulting in increased efficiency and reduced downtime. Strong attention to detail and commitment to quality, consistently exceeding expectations.

Education

Associate of Science in Manufacturing Engineering Technology

October 2019

Skills

- Chamfering Machine Operation

- Deburring Techniques

- Blueprint Reading

- Surface Finishing Techniques

- Tolerance Measurement

- Precision Cutting

Work Experience

Chamfering Machine Operator

- Monitored machine performance, identified potential issues, and performed routine maintenance to ensure smooth operation.

- Collaborated with design engineers to develop chamfering specifications, ensuring optimal edge geometry and surface finish.

- Trained and supervised junior operators, fostering a positive and productive work environment.

- Recognized for exceptional attention to detail and ability to consistently produce highquality chamfers.

Chamfering Machine Operator

- Utilized precision chamfering machines to produce highquality edges on metal components, ensuring dimensional accuracy within specified tolerances.

- Operated semiautomatic chamfering machines, consistently meeting production targets while adhering to safety protocols.

- Inspected and calibrated chamfering tools to ensure optimal performance and minimize machine downtime.

- Developed and implemented setup procedures for chamfering different metal alloys, reducing setup time and improving efficiency.

Accomplishments

- Successfully implemented a new chamfering technique that reduced production time by 15%

- Developed and implemented a quality control process that reduced defect rates by 20%

- Successfully troubleshooted and resolved a critical issue with the chamfering machine, ensuring continuous production

- Trained and mentored new chamfering machine operators, ensuring adherence to quality standards

- Optimized chamfering parameters to improve surface finish and reduce material waste

Awards

- Employee of the Year Award for Outstanding Performance in Chamfering Operations

- Safety Excellence Award for Maintaining an IncidentFree Chamfering Work Environment

- Precision Award for Achieving Exceptional Accuracy and Tolerance in Chamfering Processes

Certificates

- Certified Chamfering Machine Operator

- ISO 9001:2015 Quality Management System

- ASME B46.1 Surface Texture

- OSHA Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Chamfering Machine Operator

- Highlight your precision cutting skills and ability to work with tight tolerances

- Demonstrate your knowledge of different chamfering techniques, such as deburring, rounding, and beveling

- Quantify your accomplishments with specific metrics, such as increased efficiency or reduced downtime

- Proofread your resume carefully for any errors to showcase your attention to detail

Essential Experience Highlights for a Strong Chamfering Machine Operator Resume

- Operate semiautomatic chamfering machines, ensuring consistent production targets while adhering to safety protocols

- Inspect and calibrate chamfering tools to maintain optimal performance and minimize machine downtime

- Develop and implement setup procedures for chamfering different metal alloys, improving efficiency and reducing setup time

- Monitor machine performance, identify potential issues, and perform routine maintenance to ensure smooth operation

- Collaborate with design engineers to develop chamfering specifications, ensuring optimal edge geometry and surface finish

Frequently Asked Questions (FAQ’s) For Chamfering Machine Operator

What are the key skills required for a Chamfering Machine Operator role?

Key skills include chamfering machine operation, deburring techniques, blueprint reading, surface finishing techniques, tolerance measurement, and precision cutting.

What industries employ Chamfering Machine Operators?

The automotive, aerospace, and medical device industries heavily rely on Chamfering Machine Operators for precision component production.

What is the career path for a Chamfering Machine Operator?

With experience and additional training, Chamfering Machine Operators can advance to positions such as Quality Control Inspector, Manufacturing Supervisor, or Production Manager.

What are the safety protocols that Chamfering Machine Operators should follow?

Safety protocols include wearing appropriate PPE, following lockout/tagout procedures, and maintaining a clean and organized work area.

What is the average salary for a Chamfering Machine Operator?

The average salary for a Chamfering Machine Operator varies based on experience and location, but typically ranges between $40,000 to $60,000 per year.

What are the benefits of working as a Chamfering Machine Operator?

Benefits include competitive pay, job stability, opportunities for advancement, and the satisfaction of contributing to highquality products.