Are you a seasoned Aluminum Polisher seeking a new career path? Discover our professionally built Aluminum Polisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

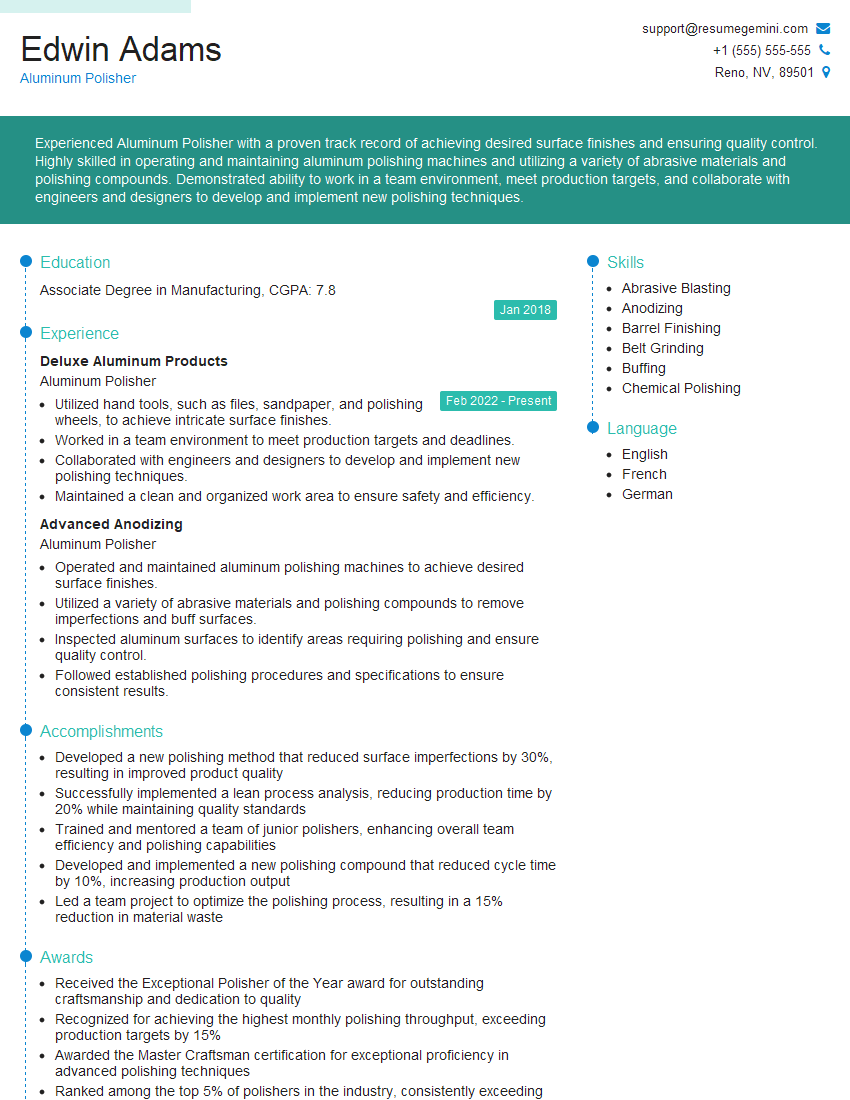

Edwin Adams

Aluminum Polisher

Summary

Experienced Aluminum Polisher with a proven track record of achieving desired surface finishes and ensuring quality control. Highly skilled in operating and maintaining aluminum polishing machines and utilizing a variety of abrasive materials and polishing compounds. Demonstrated ability to work in a team environment, meet production targets, and collaborate with engineers and designers to develop and implement new polishing techniques.

Education

Associate Degree in Manufacturing

January 2018

Skills

- Abrasive Blasting

- Anodizing

- Barrel Finishing

- Belt Grinding

- Buffing

- Chemical Polishing

Work Experience

Aluminum Polisher

- Utilized hand tools, such as files, sandpaper, and polishing wheels, to achieve intricate surface finishes.

- Worked in a team environment to meet production targets and deadlines.

- Collaborated with engineers and designers to develop and implement new polishing techniques.

- Maintained a clean and organized work area to ensure safety and efficiency.

Aluminum Polisher

- Operated and maintained aluminum polishing machines to achieve desired surface finishes.

- Utilized a variety of abrasive materials and polishing compounds to remove imperfections and buff surfaces.

- Inspected aluminum surfaces to identify areas requiring polishing and ensure quality control.

- Followed established polishing procedures and specifications to ensure consistent results.

Accomplishments

- Developed a new polishing method that reduced surface imperfections by 30%, resulting in improved product quality

- Successfully implemented a lean process analysis, reducing production time by 20% while maintaining quality standards

- Trained and mentored a team of junior polishers, enhancing overall team efficiency and polishing capabilities

- Developed and implemented a new polishing compound that reduced cycle time by 10%, increasing production output

- Led a team project to optimize the polishing process, resulting in a 15% reduction in material waste

Awards

- Received the Exceptional Polisher of the Year award for outstanding craftsmanship and dedication to quality

- Recognized for achieving the highest monthly polishing throughput, exceeding production targets by 15%

- Awarded the Master Craftsman certification for exceptional proficiency in advanced polishing techniques

- Ranked among the top 5% of polishers in the industry, consistently exceeding quality and performance benchmarks

Certificates

- Certified Aluminum Polisher

- Certified Industrial Polisher

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Aluminum Polisher

- Quantify your accomplishments with specific metrics and results.

- Highlight your experience and skills in specialized polishing techniques, such as abrasive blasting, anodizing, and chemical polishing.

- Showcase your ability to work independently and as part of a team to achieve project goals.

- Demonstrate your commitment to safety and quality by mentioning industry certifications or awards received.

Essential Experience Highlights for a Strong Aluminum Polisher Resume

- Operate and maintain aluminum polishing machines to achieve desired surface finishes.

- Utilize a variety of abrasive materials and polishing compounds to remove imperfections and buff surfaces.

- Inspect aluminum surfaces to identify areas requiring polishing and ensure quality control.

- Follow established polishing procedures and specifications to ensure consistent results.

- Utilize hand tools, such as files, sandpaper, and polishing wheels, to achieve intricate surface finishes.

- Work in a team environment to meet production targets and deadlines.

- Collaborate with engineers and designers to develop and implement new polishing techniques.

Frequently Asked Questions (FAQ’s) For Aluminum Polisher

What are the key skills required to be an Aluminum Polisher?

Key skills for an Aluminum Polisher include operating and maintaining aluminum polishing machines, proficiency in using abrasive materials and polishing compounds, ability to inspect surfaces for imperfections, following established polishing procedures, utilizing hand tools for intricate finishes, working in a team environment, and collaborating with engineers and designers.

What are the career opportunities for an Aluminum Polisher?

Aluminum Polishers can find employment in a variety of industries, including aerospace, automotive, construction, and manufacturing. They may also work in polishing shops or as part of a specialized finishing team.

What is the average salary for an Aluminum Polisher?

The average salary for an Aluminum Polisher can vary depending on experience, location, and industry. According to Indeed, the average salary for an Aluminum Polisher in the United States is approximately $45,000 per year.

What are the educational requirements for an Aluminum Polisher?

While no formal education is typically required, Aluminum Polishers may benefit from an associate degree or certificate in manufacturing, metalworking, or a related field.

What are the safety precautions that should be taken when working as an Aluminum Polisher?

Aluminum Polishers should wear appropriate safety gear, including gloves, safety glasses, and a respirator when working with abrasive materials and polishing compounds. They should also ensure proper ventilation in the workspace to avoid inhaling harmful fumes or dust.

What are the challenges faced by Aluminum Polishers?

Aluminum Polishers may face challenges such as working with intricate or delicate surfaces, ensuring consistent and high-quality finishes, and meeting tight deadlines while maintaining accuracy and precision.

How can I improve my skills as an Aluminum Polisher?

To improve your skills as an Aluminum Polisher, consider seeking additional training or certification in specialized polishing techniques, experimenting with different abrasive materials and polishing compounds to achieve desired effects, and seeking feedback from experienced professionals to refine your approach.

What are the industry trends in Aluminum Polishing?

The Aluminum Polishing industry is constantly evolving with advancements in technology. Automated polishing machines and the use of eco-friendly polishing compounds are becoming more prevalent. Stay updated with industry trends and best practices to enhance your skills and stay competitive.