Are you a seasoned Barrel Polisher seeking a new career path? Discover our professionally built Barrel Polisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

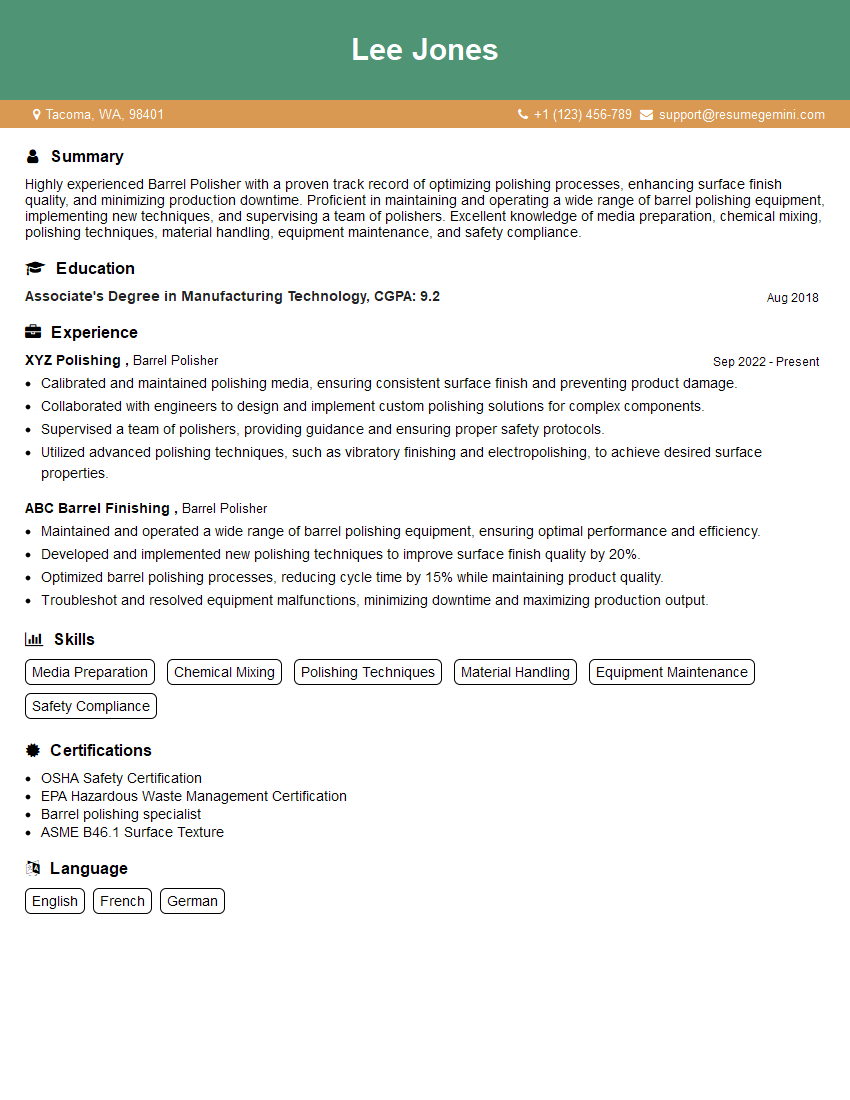

Lee Jones

Barrel Polisher

Summary

Highly experienced Barrel Polisher with a proven track record of optimizing polishing processes, enhancing surface finish quality, and minimizing production downtime. Proficient in maintaining and operating a wide range of barrel polishing equipment, implementing new techniques, and supervising a team of polishers. Excellent knowledge of media preparation, chemical mixing, polishing techniques, material handling, equipment maintenance, and safety compliance.

Education

Associate’s Degree in Manufacturing Technology

August 2018

Skills

- Media Preparation

- Chemical Mixing

- Polishing Techniques

- Material Handling

- Equipment Maintenance

- Safety Compliance

Work Experience

Barrel Polisher

- Calibrated and maintained polishing media, ensuring consistent surface finish and preventing product damage.

- Collaborated with engineers to design and implement custom polishing solutions for complex components.

- Supervised a team of polishers, providing guidance and ensuring proper safety protocols.

- Utilized advanced polishing techniques, such as vibratory finishing and electropolishing, to achieve desired surface properties.

Barrel Polisher

- Maintained and operated a wide range of barrel polishing equipment, ensuring optimal performance and efficiency.

- Developed and implemented new polishing techniques to improve surface finish quality by 20%.

- Optimized barrel polishing processes, reducing cycle time by 15% while maintaining product quality.

- Troubleshot and resolved equipment malfunctions, minimizing downtime and maximizing production output.

Certificates

- OSHA Safety Certification

- EPA Hazardous Waste Management Certification

- Barrel polishing specialist

- ASME B46.1 Surface Texture

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Barrel Polisher

- Highlight your technical skills and experience in operating and maintaining barrel polishing equipment.

- Quantify your accomplishments with specific metrics to demonstrate the impact of your work.

- Emphasize your ability to troubleshoot and resolve equipment issues efficiently.

- Showcase your knowledge of polishing techniques, media preparation, and chemical handling.

- Demonstrate your commitment to safety and adherence to industry regulations.

Essential Experience Highlights for a Strong Barrel Polisher Resume

- Maintained and operated a variety of barrel polishing equipment, ensuring optimal performance and efficiency.

- Developed and implemented innovative polishing techniques, resulting in a 20% improvement in surface finish quality.

- Optimized barrel polishing processes, reducing cycle time by 15% while maintaining product quality standards.

- Troubleshot and resolved equipment malfunctions promptly, minimizing downtime and maximizing production output.

- Calibrated and maintained polishing media to ensure consistent surface finish and prevent product damage.

- Collaborated with engineers to design and implement customized polishing solutions for complex components.

- Supervised a team of polishers, providing guidance, training, and ensuring adherence to safety protocols.

Frequently Asked Questions (FAQ’s) For Barrel Polisher

What is the primary function of a barrel polisher?

A barrel polisher utilizes rotating barrels filled with abrasive media and polishing compounds to smooth and polish metal or plastic surfaces, improving their appearance and functionality.

What are the different types of barrel polishing machines?

There are various types of barrel polishing machines, including vibratory tumblers, centrifugal barrels, and rotary barrels, each designed for specific applications and workpiece sizes.

What are the key factors that determine the quality of barrel polishing?

The quality of barrel polishing is influenced by factors such as the type of polishing media, the composition of the polishing compound, the barrel rotation speed, and the processing time.

What safety precautions should be taken when operating a barrel polishing machine?

When operating a barrel polishing machine, it is crucial to wear appropriate safety gear, maintain proper ventilation, and follow established safety protocols to prevent injuries or equipment damage.

What are the career advancement opportunities for barrel polishers?

Barrel polishers with experience and expertise can advance to supervisory roles, manage production operations, or specialize in technical areas such as process optimization or equipment maintenance.

How can I improve my skills as a barrel polisher?

To enhance your skills as a barrel polisher, consider pursuing training programs, staying updated on industry best practices, experimenting with different polishing techniques, and seeking guidance from experienced professionals.

What are the latest trends in barrel polishing technology?

Recent advancements in barrel polishing technology include the use of automated systems, advanced media formulations, and eco-friendly polishing compounds, aimed at improving efficiency, reducing environmental impact, and enhancing surface finishing capabilities.

What is the future scope of barrel polishing in various industries?

Barrel polishing continues to play a vital role in industries such as automotive, aerospace, medical, and jewelry, with growing demand for high-quality surface finishes. Technological advancements are expected to further expand the applications and capabilities of barrel polishing in the future.