Are you a seasoned Burring Wheel Operator seeking a new career path? Discover our professionally built Burring Wheel Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

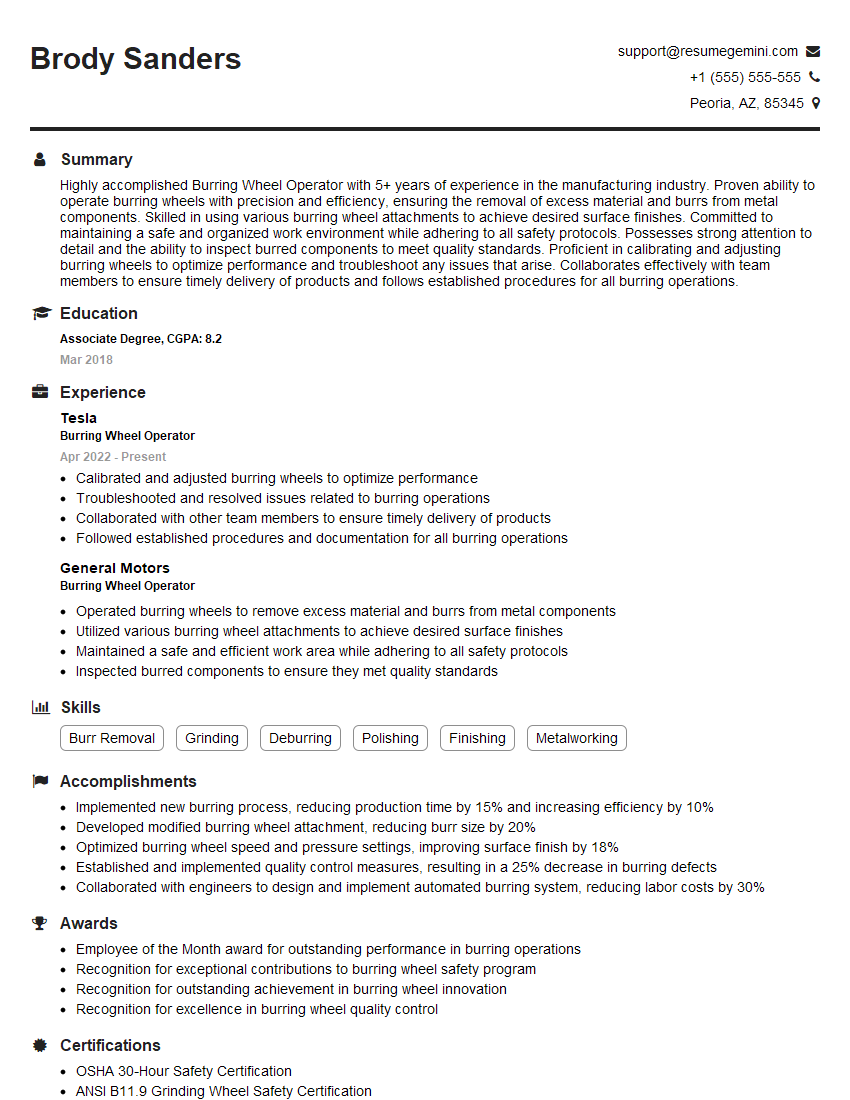

Brody Sanders

Burring Wheel Operator

Summary

Highly accomplished Burring Wheel Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate burring wheels with precision and efficiency, ensuring the removal of excess material and burrs from metal components. Skilled in using various burring wheel attachments to achieve desired surface finishes. Committed to maintaining a safe and organized work environment while adhering to all safety protocols. Possesses strong attention to detail and the ability to inspect burred components to meet quality standards. Proficient in calibrating and adjusting burring wheels to optimize performance and troubleshoot any issues that arise. Collaborates effectively with team members to ensure timely delivery of products and follows established procedures for all burring operations.

Education

Associate Degree

March 2018

Skills

- Burr Removal

- Grinding

- Deburring

- Polishing

- Finishing

- Metalworking

Work Experience

Burring Wheel Operator

- Calibrated and adjusted burring wheels to optimize performance

- Troubleshooted and resolved issues related to burring operations

- Collaborated with other team members to ensure timely delivery of products

- Followed established procedures and documentation for all burring operations

Burring Wheel Operator

- Operated burring wheels to remove excess material and burrs from metal components

- Utilized various burring wheel attachments to achieve desired surface finishes

- Maintained a safe and efficient work area while adhering to all safety protocols

- Inspected burred components to ensure they met quality standards

Accomplishments

- Implemented new burring process, reducing production time by 15% and increasing efficiency by 10%

- Developed modified burring wheel attachment, reducing burr size by 20%

- Optimized burring wheel speed and pressure settings, improving surface finish by 18%

- Established and implemented quality control measures, resulting in a 25% decrease in burring defects

- Collaborated with engineers to design and implement automated burring system, reducing labor costs by 30%

Awards

- Employee of the Month award for outstanding performance in burring operations

- Recognition for exceptional contributions to burring wheel safety program

- Recognition for outstanding achievement in burring wheel innovation

- Recognition for excellence in burring wheel quality control

Certificates

- OSHA 30-Hour Safety Certification

- ANSI B11.9 Grinding Wheel Safety Certification

- AWS D1.1 Structural Welding Code Certification

- ASME Boiler and Pressure Vessel Code Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Burring Wheel Operator

- Quantify your accomplishments whenever possible. For example, instead of simply stating that you operated burring wheels, provide specific details about the number of components you processed or the efficiency improvements you achieved.

- Highlight your technical skills and knowledge. Describe your proficiency in using different types of burring wheels and attachments, as well as your ability to calibrate and adjust them for optimal performance.

- Demonstrate your commitment to safety. Emphasize your understanding of safety protocols and your track record of maintaining a safe work environment.

- Showcase your teamwork and communication skills. Explain how you collaborated with other team members to ensure timely delivery of products and how you effectively communicated any issues or concerns.

Essential Experience Highlights for a Strong Burring Wheel Operator Resume

- Operated burring wheels to remove excess material and burrs from metal components, ensuring a smooth and clean finish.

- Utilized various burring wheel attachments, such as carbide burrs, abrasive brushes, and polishing wheels, to achieve different surface finishes.

- Maintained a safe and efficient work area by adhering to all safety protocols, including the use of proper personal protective equipment.

- Inspected burred components to ensure they met quality standards, identifying and correcting any defects.

- Calibrated and adjusted burring wheels to optimize performance and extend their lifespan.

- Troubleshooted and resolved issues related to burring operations, ensuring minimal disruptions to production.

- Followed established procedures and documentation for all burring operations, maintaining accurate records and ensuring compliance.

Frequently Asked Questions (FAQ’s) For Burring Wheel Operator

What is the primary role of a Burring Wheel Operator?

The primary role of a Burring Wheel Operator is to remove excess material and burrs from metal components using burring wheels. This process ensures that the components meet the required surface finish specifications and quality standards.

What skills are essential for a successful Burring Wheel Operator?

Essential skills for a successful Burring Wheel Operator include proficiency in operating burring wheels, attention to detail, knowledge of different surface finishes, and the ability to work safely and efficiently in a manufacturing environment.

Is it necessary to have a college degree to become a Burring Wheel Operator?

While some employers may prefer candidates with an associate degree or certification in a related field, it is not always a requirement to become a Burring Wheel Operator. Many individuals enter the field through on-the-job training or apprenticeship programs.

What are the career advancement opportunities for a Burring Wheel Operator?

With experience and additional training, Burring Wheel Operators can advance to roles such as Quality Control Inspector, Production Supervisor, or Manufacturing Engineer.

How can I improve my chances of getting hired as a Burring Wheel Operator?

To improve your chances of getting hired as a Burring Wheel Operator, consider gaining hands-on experience through internships or volunteering, obtaining relevant certifications, and showcasing your skills and knowledge during the interview process.

What are the typical working conditions for a Burring Wheel Operator?

Burring Wheel Operators typically work in manufacturing facilities or workshops. The work environment may involve exposure to noise, dust, and chemicals. Maintaining proper safety precautions and wearing appropriate personal protective equipment is crucial.

What is the average salary range for a Burring Wheel Operator?

The average annual salary range for a Burring Wheel Operator in the United States is between $30,000 to $50,000, depending on experience, location, and industry.