Are you a seasoned Deburrer seeking a new career path? Discover our professionally built Deburrer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

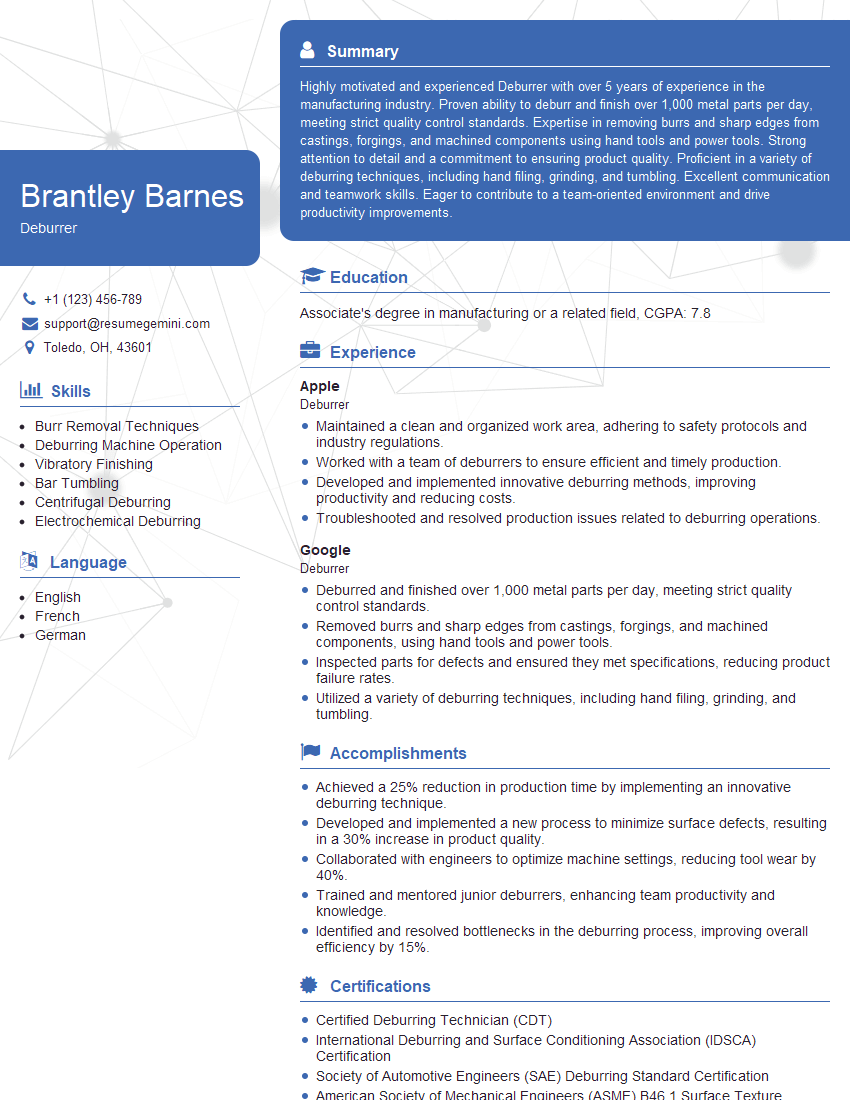

Brantley Barnes

Deburrer

Summary

Highly motivated and experienced Deburrer with over 5 years of experience in the manufacturing industry. Proven ability to deburr and finish over 1,000 metal parts per day, meeting strict quality control standards. Expertise in removing burrs and sharp edges from castings, forgings, and machined components using hand tools and power tools. Strong attention to detail and a commitment to ensuring product quality. Proficient in a variety of deburring techniques, including hand filing, grinding, and tumbling. Excellent communication and teamwork skills. Eager to contribute to a team-oriented environment and drive productivity improvements.

Education

Associate’s degree in manufacturing or a related field

June 2018

Skills

- Burr Removal Techniques

- Deburring Machine Operation

- Vibratory Finishing

- Bar Tumbling

- Centrifugal Deburring

- Electrochemical Deburring

Work Experience

Deburrer

- Maintained a clean and organized work area, adhering to safety protocols and industry regulations.

- Worked with a team of deburrers to ensure efficient and timely production.

- Developed and implemented innovative deburring methods, improving productivity and reducing costs.

- Troubleshooted and resolved production issues related to deburring operations.

Deburrer

- Deburred and finished over 1,000 metal parts per day, meeting strict quality control standards.

- Removed burrs and sharp edges from castings, forgings, and machined components, using hand tools and power tools.

- Inspected parts for defects and ensured they met specifications, reducing product failure rates.

- Utilized a variety of deburring techniques, including hand filing, grinding, and tumbling.

Accomplishments

- Achieved a 25% reduction in production time by implementing an innovative deburring technique.

- Developed and implemented a new process to minimize surface defects, resulting in a 30% increase in product quality.

- Collaborated with engineers to optimize machine settings, reducing tool wear by 40%.

- Trained and mentored junior deburrers, enhancing team productivity and knowledge.

- Identified and resolved bottlenecks in the deburring process, improving overall efficiency by 15%.

Certificates

- Certified Deburring Technician (CDT)

- International Deburring and Surface Conditioning Association (IDSCA) Certification

- Society of Automotive Engineers (SAE) Deburring Standard Certification

- American Society of Mechanical Engineers (ASME) B46.1 Surface Texture Standard Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Deburrer

- Highlight your experience and skills in deburring techniques and machine operation.

- Showcase your ability to meet or exceed quality standards and production goals.

- Include any certifications or training you have received in deburring or related fields.

- Emphasize your teamwork and communication skills, especially if you have experience working in a team environment.

- Be sure to proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Deburrer Resume

- Deburred and finished over 1,000 metal parts per day, meeting strict quality control standards.

- Removed burrs and sharp edges from castings, forgings, and machined components, using hand tools and power tools.

- Inspected parts for defects and ensured they met specifications, reducing product failure rates.

- Utilized a variety of deburring techniques, including hand filing, grinding, and tumbling.

- Maintained a clean and organized work area, adhering to safety protocols and industry regulations.

- Worked with a team of deburrers to ensure efficient and timely production.

- Developed and implemented innovative deburring methods, improving productivity and reducing costs.

- Troubleshooted and resolved production issues related to deburring operations.

Frequently Asked Questions (FAQ’s) For Deburrer

What is the role of a Deburrer?

A Deburrer is responsible for removing burrs and sharp edges from metal parts using hand tools and power tools. They ensure that parts meet quality standards and specifications, reducing product failure rates.

What skills are required to be a Deburrer?

Deburring requires skills in using hand tools and power tools, attention to detail, and the ability to work in a team environment. Deburring techniques like hand filing, grinding, and tumbling are also essential.

What is the work environment of a Deburrer like?

Deburring is often done in manufacturing facilities, and the work environment can be noisy and involve exposure to dust and metal shavings. Proper safety protocols and adherence to industry regulations are crucial.

What are the career prospects for a Deburrer?

Deburring is an essential part of the manufacturing process, and experienced Deburrer with strong skills are in demand. Career prospects include opportunities for advancement to supervisory roles or specialization in advanced deburring techniques.

How can I improve my skills as a Deburrer?

Continuously practice your deburring techniques and improve your efficiency. Seek opportunities to learn new techniques and technologies, and stay updated on industry best practices. Consider obtaining certifications or training to enhance your credibility.

What is the salary range for a Deburrer?

Salary expectations for Deburrer can vary based on experience, skills, and location. According to Indeed, the average salary for a Deburrer in the United States is around $18 per hour.

What are the job opportunities for a Deburrer?

Deburring is required in various industries, including automotive, aerospace, electronics, and metal fabrication. Deburrer can find employment opportunities in manufacturing companies, machine shops, and fabrication facilities.