Are you a seasoned Edging Machine Operator seeking a new career path? Discover our professionally built Edging Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

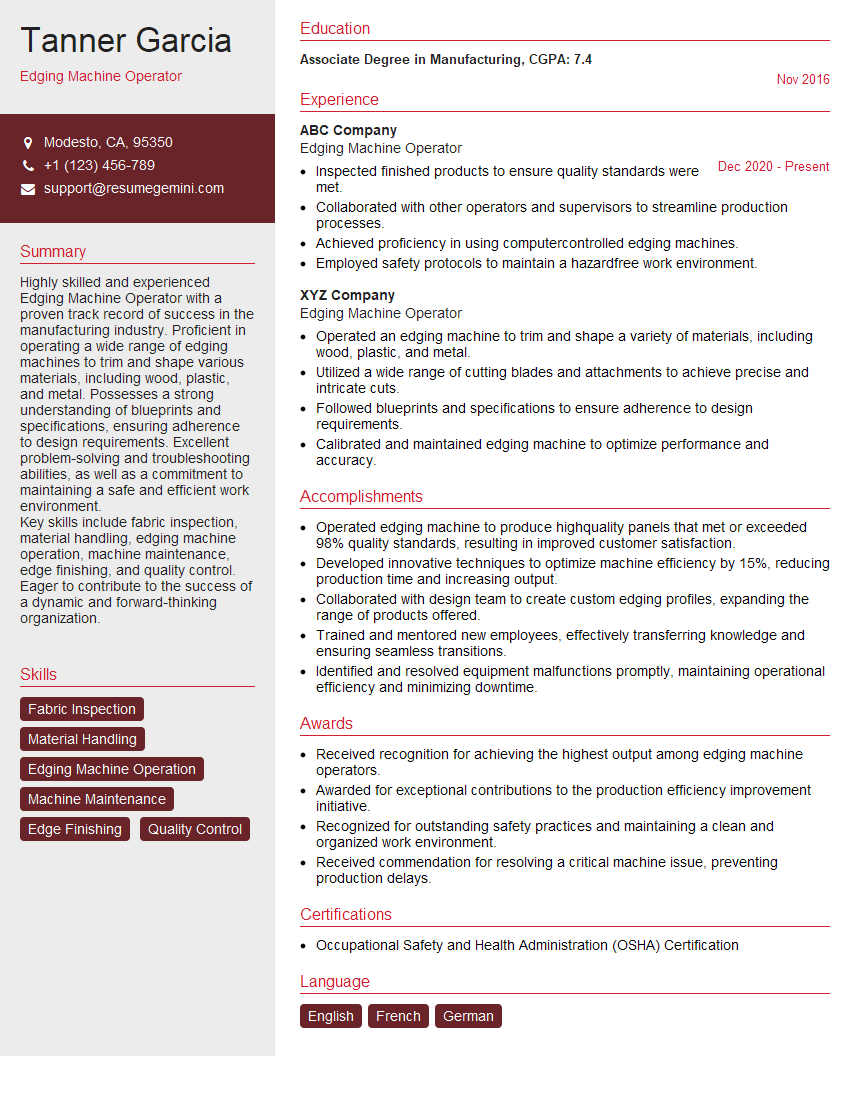

Tanner Garcia

Edging Machine Operator

Summary

Highly skilled and experienced Edging Machine Operator with a proven track record of success in the manufacturing industry. Proficient in operating a wide range of edging machines to trim and shape various materials, including wood, plastic, and metal. Possesses a strong understanding of blueprints and specifications, ensuring adherence to design requirements. Excellent problem-solving and troubleshooting abilities, as well as a commitment to maintaining a safe and efficient work environment.

Key skills include fabric inspection, material handling, edging machine operation, machine maintenance, edge finishing, and quality control. Eager to contribute to the success of a dynamic and forward-thinking organization.

Education

Associate Degree in Manufacturing

November 2016

Skills

- Fabric Inspection

- Material Handling

- Edging Machine Operation

- Machine Maintenance

- Edge Finishing

- Quality Control

Work Experience

Edging Machine Operator

- Inspected finished products to ensure quality standards were met.

- Collaborated with other operators and supervisors to streamline production processes.

- Achieved proficiency in using computercontrolled edging machines.

- Employed safety protocols to maintain a hazardfree work environment.

Edging Machine Operator

- Operated an edging machine to trim and shape a variety of materials, including wood, plastic, and metal.

- Utilized a wide range of cutting blades and attachments to achieve precise and intricate cuts.

- Followed blueprints and specifications to ensure adherence to design requirements.

- Calibrated and maintained edging machine to optimize performance and accuracy.

Accomplishments

- Operated edging machine to produce highquality panels that met or exceeded 98% quality standards, resulting in improved customer satisfaction.

- Developed innovative techniques to optimize machine efficiency by 15%, reducing production time and increasing output.

- Collaborated with design team to create custom edging profiles, expanding the range of products offered.

- Trained and mentored new employees, effectively transferring knowledge and ensuring seamless transitions.

- Identified and resolved equipment malfunctions promptly, maintaining operational efficiency and minimizing downtime.

Awards

- Received recognition for achieving the highest output among edging machine operators.

- Awarded for exceptional contributions to the production efficiency improvement initiative.

- Recognized for outstanding safety practices and maintaining a clean and organized work environment.

- Received commendation for resolving a critical machine issue, preventing production delays.

Certificates

- Occupational Safety and Health Administration (OSHA) Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Edging Machine Operator

- Highlight your experience and skills in operating different types of edging machines.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact.

- Emphasize your understanding of blueprints and specifications, as well as your ability to follow instructions.

- Showcase your commitment to quality control and safety.

Essential Experience Highlights for a Strong Edging Machine Operator Resume

- Operate edging machines to trim and shape a variety of materials, including wood, plastic, and metal.

- Utilize a wide range of cutting blades and attachments to achieve precise and intricate cuts.

- Follow blueprints and specifications to ensure adherence to design requirements.

- Calibrate and maintain edging machine to optimize performance and accuracy.

- Inspect finished products to ensure quality standards are met.

- Collaborate with other operators and supervisors to streamline production processes.

Frequently Asked Questions (FAQ’s) For Edging Machine Operator

What is the primary role of an Edging Machine Operator?

The primary role of an Edging Machine Operator is to operate edging machines to trim and shape a variety of materials, ensuring adherence to design specifications and quality standards.

What are the key skills required for an Edging Machine Operator?

Key skills for an Edging Machine Operator include fabric inspection, material handling, edging machine operation, machine maintenance, edge finishing, and quality control.

What type of education is required to become an Edging Machine Operator?

While formal education requirements may vary, many Edging Machine Operators hold an Associate Degree in Manufacturing or a related field.

What are the career prospects for an Edging Machine Operator?

Edging Machine Operators can advance to supervisory roles, such as Production Supervisor or Quality Control Manager. They can also specialize in operating specific types of edging machines or materials.

What is the work environment like for an Edging Machine Operator?

Edging Machine Operators typically work in manufacturing facilities, operating machinery in a fast-paced environment. They must adhere to safety protocols and maintain a clean and organized work area.

What are the safety precautions that Edging Machine Operators must follow?

Edging Machine Operators must follow safety protocols to maintain a hazard-free work environment, including wearing appropriate safety gear, following lockout/tagout procedures, and being aware of potential hazards associated with operating machinery.