Are you a seasoned Enamel Buffer seeking a new career path? Discover our professionally built Enamel Buffer Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

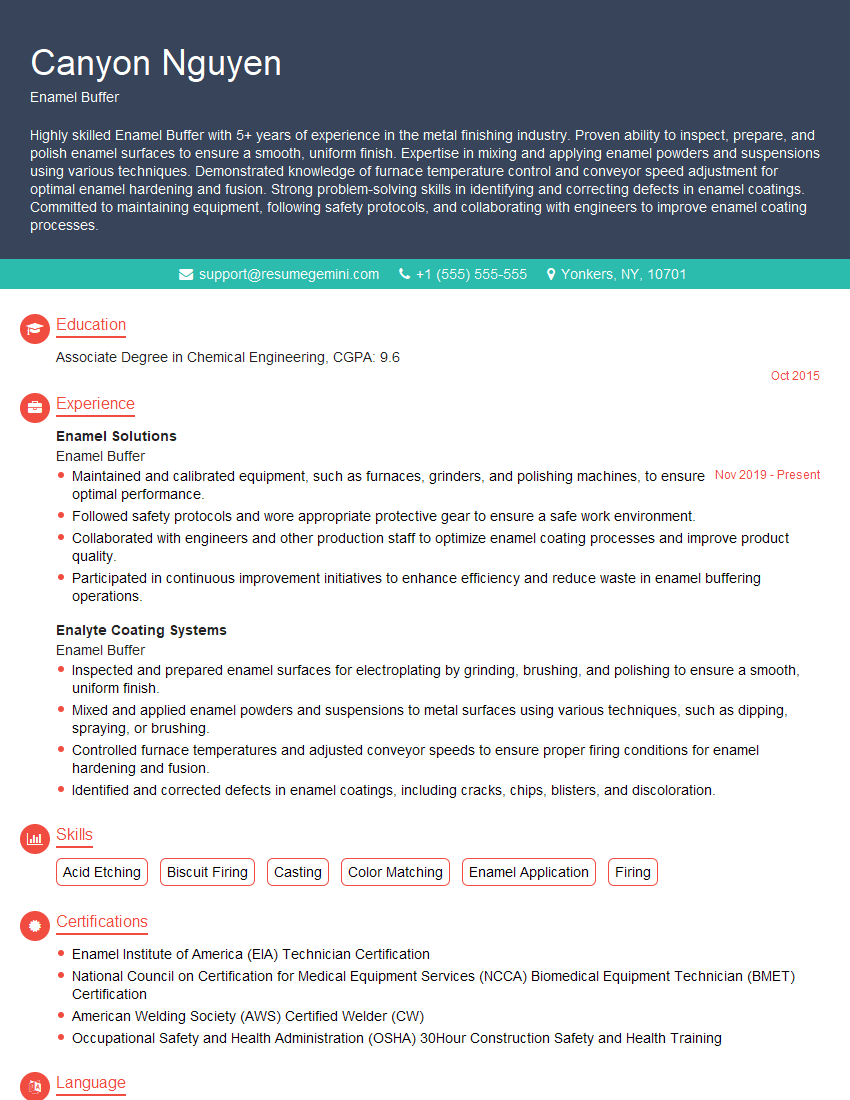

Canyon Nguyen

Enamel Buffer

Summary

Highly skilled Enamel Buffer with 5+ years of experience in the metal finishing industry. Proven ability to inspect, prepare, and polish enamel surfaces to ensure a smooth, uniform finish. Expertise in mixing and applying enamel powders and suspensions using various techniques. Demonstrated knowledge of furnace temperature control and conveyor speed adjustment for optimal enamel hardening and fusion. Strong problem-solving skills in identifying and correcting defects in enamel coatings. Committed to maintaining equipment, following safety protocols, and collaborating with engineers to improve enamel coating processes.

Education

Associate Degree in Chemical Engineering

October 2015

Skills

- Acid Etching

- Biscuit Firing

- Casting

- Color Matching

- Enamel Application

- Firing

Work Experience

Enamel Buffer

- Maintained and calibrated equipment, such as furnaces, grinders, and polishing machines, to ensure optimal performance.

- Followed safety protocols and wore appropriate protective gear to ensure a safe work environment.

- Collaborated with engineers and other production staff to optimize enamel coating processes and improve product quality.

- Participated in continuous improvement initiatives to enhance efficiency and reduce waste in enamel buffering operations.

Enamel Buffer

- Inspected and prepared enamel surfaces for electroplating by grinding, brushing, and polishing to ensure a smooth, uniform finish.

- Mixed and applied enamel powders and suspensions to metal surfaces using various techniques, such as dipping, spraying, or brushing.

- Controlled furnace temperatures and adjusted conveyor speeds to ensure proper firing conditions for enamel hardening and fusion.

- Identified and corrected defects in enamel coatings, including cracks, chips, blisters, and discoloration.

Certificates

- Enamel Institute of America (EIA) Technician Certification

- National Council on Certification for Medical Equipment Services (NCCA) Biomedical Equipment Technician (BMET) Certification

- American Welding Society (AWS) Certified Welder (CW)

- Occupational Safety and Health Administration (OSHA) 30Hour Construction Safety and Health Training

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Enamel Buffer

- Highlight your technical skills and experience in enamel buffering, including specific techniques and equipment you have worked with.

- Quantify your accomplishments whenever possible, using specific numbers and metrics to demonstrate your impact on the job.

- Showcase your knowledge of enamel coating processes and your ability to troubleshoot and solve problems.

- Emphasize your attention to detail and commitment to quality.

- Proofread your resume carefully for any errors before submitting it.

Essential Experience Highlights for a Strong Enamel Buffer Resume

- Inspected and prepared enamel surfaces for electroplating by grinding, brushing, and polishing to ensure a smooth, uniform finish.

- Mixed and applied enamel powders and suspensions to metal surfaces using various techniques, such as dipping, spraying, or brushing.

- Controlled furnace temperatures and adjusted conveyor speeds to ensure proper firing conditions for enamel hardening and fusion.

- Identified and corrected defects in enamel coatings, including cracks, chips, blisters, and discoloration.

- Maintained and calibrated equipment, such as furnaces, grinders, and polishing machines, to ensure optimal performance.

- Followed safety protocols and wore appropriate protective gear to ensure a safe work environment.

- Collaborated with engineers and other production staff to optimize enamel coating processes and improve product quality.

Frequently Asked Questions (FAQ’s) For Enamel Buffer

What is the primary role of an Enamel Buffer?

The primary role of an Enamel Buffer is to inspect and prepare enamel surfaces for electroplating, mix and apply enamel powders and suspensions, control furnace temperatures, identify and correct defects, maintain equipment, and collaborate with engineers to optimize enamel coating processes.

What are the essential skills required for an Enamel Buffer?

Essential skills for an Enamel Buffer include acid etching, biscuit firing, casting, color matching, enamel application, and firing.

What are the career prospects for an Enamel Buffer?

Enamel Buffers can advance to positions such as Quality Control Inspector, Production Supervisor, or Technical Manager.

How can I improve my chances of getting hired as an Enamel Buffer?

To improve your chances of getting hired as an Enamel Buffer, you can obtain a relevant degree or certification, gain practical experience through internships or apprenticeships, and build a strong resume and cover letter.

What is the average salary for an Enamel Buffer?

The average salary for an Enamel Buffer in the United States is around $35,000 per year.

What are the working conditions for an Enamel Buffer?

Enamel Buffers typically work in factories or industrial settings and may be exposed to fumes, dust, and noise.

Is it necessary to have a college degree to become an Enamel Buffer?

While a college degree is not always required, it can be beneficial in obtaining a higher-level position in the field.

What are some of the challenges faced by Enamel Buffers?

Some of the challenges faced by Enamel Buffers include ensuring the quality and consistency of enamel coatings, meeting production deadlines, and working in potentially hazardous conditions.