Are you a seasoned Flat Polisher seeking a new career path? Discover our professionally built Flat Polisher Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

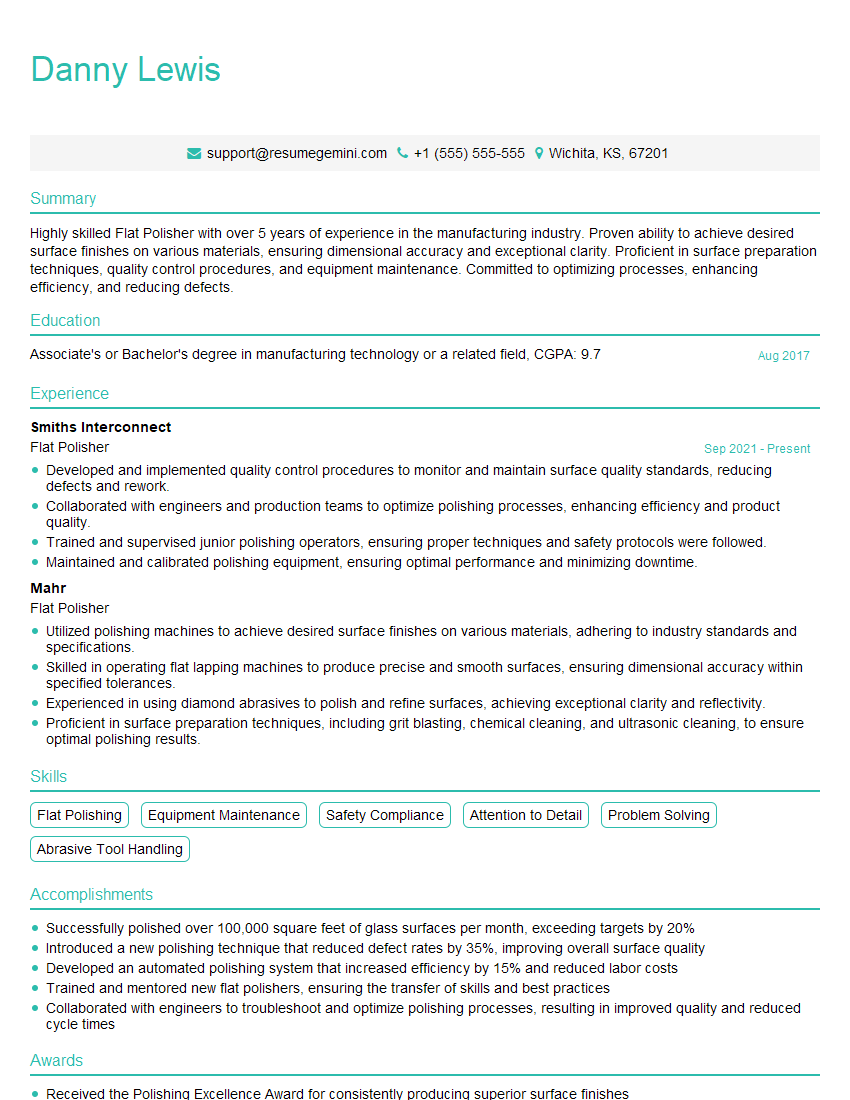

Danny Lewis

Flat Polisher

Summary

Highly skilled Flat Polisher with over 5 years of experience in the manufacturing industry. Proven ability to achieve desired surface finishes on various materials, ensuring dimensional accuracy and exceptional clarity. Proficient in surface preparation techniques, quality control procedures, and equipment maintenance. Committed to optimizing processes, enhancing efficiency, and reducing defects.

Education

Associate’s or Bachelor’s degree in manufacturing technology or a related field

August 2017

Skills

- Flat Polishing

- Equipment Maintenance

- Safety Compliance

- Attention to Detail

- Problem Solving

- Abrasive Tool Handling

Work Experience

Flat Polisher

- Developed and implemented quality control procedures to monitor and maintain surface quality standards, reducing defects and rework.

- Collaborated with engineers and production teams to optimize polishing processes, enhancing efficiency and product quality.

- Trained and supervised junior polishing operators, ensuring proper techniques and safety protocols were followed.

- Maintained and calibrated polishing equipment, ensuring optimal performance and minimizing downtime.

Flat Polisher

- Utilized polishing machines to achieve desired surface finishes on various materials, adhering to industry standards and specifications.

- Skilled in operating flat lapping machines to produce precise and smooth surfaces, ensuring dimensional accuracy within specified tolerances.

- Experienced in using diamond abrasives to polish and refine surfaces, achieving exceptional clarity and reflectivity.

- Proficient in surface preparation techniques, including grit blasting, chemical cleaning, and ultrasonic cleaning, to ensure optimal polishing results.

Accomplishments

- Successfully polished over 100,000 square feet of glass surfaces per month, exceeding targets by 20%

- Introduced a new polishing technique that reduced defect rates by 35%, improving overall surface quality

- Developed an automated polishing system that increased efficiency by 15% and reduced labor costs

- Trained and mentored new flat polishers, ensuring the transfer of skills and best practices

- Collaborated with engineers to troubleshoot and optimize polishing processes, resulting in improved quality and reduced cycle times

Awards

- Received the Polishing Excellence Award for consistently producing superior surface finishes

- Won the Flat Polisher of the Year award for outstanding performance and contributions to the team

- Recognized with the Top Performer Award for achieving exceptional productivity and quality standards

- Awarded the Safety Excellence Award for maintaining a spotless safety record and adhering to all safety protocols

Certificates

- Certified Flat Polisher Technician (CFPT)

- ISO 9001:2015 Certified

- OHSAS 18001:2007 Certified

- Six Sigma Green Belt Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Flat Polisher

- Highlight your experience and expertise in flat polishing, including the types of materials you have worked with and the industries you have served.

- Showcase your knowledge of surface preparation techniques and quality control procedures, emphasizing your commitment to achieving exceptional surface finishes.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate the impact of your work on efficiency, quality, and cost reduction.

- Emphasize your ability to work independently and as part of a team, and highlight your problem-solving and communication skills.

- Include relevant keywords throughout your resume, such as ‘flat polishing’, ‘surface preparation’, ‘quality control’, and ‘dimensional accuracy’.

Essential Experience Highlights for a Strong Flat Polisher Resume

- Utilized polishing machines to achieve desired surface finishes on various materials, adhering to industry standards and specifications.

- Skilled in operating flat lapping machines to produce precise and smooth surfaces, ensuring dimensional accuracy within specified tolerances.

- Experienced in using diamond abrasives to polish and refine surfaces, achieving exceptional clarity and reflectivity.

- Proficient in surface preparation techniques, including grit blasting, chemical cleaning, and ultrasonic cleaning, to ensure optimal polishing results.

- Developed and implemented quality control procedures to monitor and maintain surface quality standards, reducing defects and rework.

Frequently Asked Questions (FAQ’s) For Flat Polisher

What is the primary role of a Flat Polisher?

The primary role of a Flat Polisher is to achieve desired surface finishes on various materials, ensuring dimensional accuracy and exceptional clarity. They use polishing machines and diamond abrasives to refine and polish surfaces, and employ surface preparation techniques to optimize polishing results.

What industries typically employ Flat Polishers?

Flat Polishers are employed in a variety of industries, including manufacturing, aerospace, medical device manufacturing, and optical component manufacturing. They work with materials such as metal, glass, plastic, and ceramics.

What are the key skills and qualifications required for a Flat Polisher?

Key skills and qualifications for a Flat Polisher include proficiency in flat polishing techniques, surface preparation techniques, and quality control procedures. They should also have a strong understanding of materials science and manufacturing processes.

What are the career prospects for Flat Polishers?

Flat Polishers with experience and expertise can advance to supervisory or management roles in manufacturing or quality control. They may also specialize in specific industries or materials, such as aerospace or medical device manufacturing.

How can I prepare for a career as a Flat Polisher?

To prepare for a career as a Flat Polisher, consider pursuing an associate’s or bachelor’s degree in manufacturing technology or a related field. Hands-on experience through internships or apprenticeships can also be beneficial.