Are you a seasoned Gear Lapping Machine Operator seeking a new career path? Discover our professionally built Gear Lapping Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

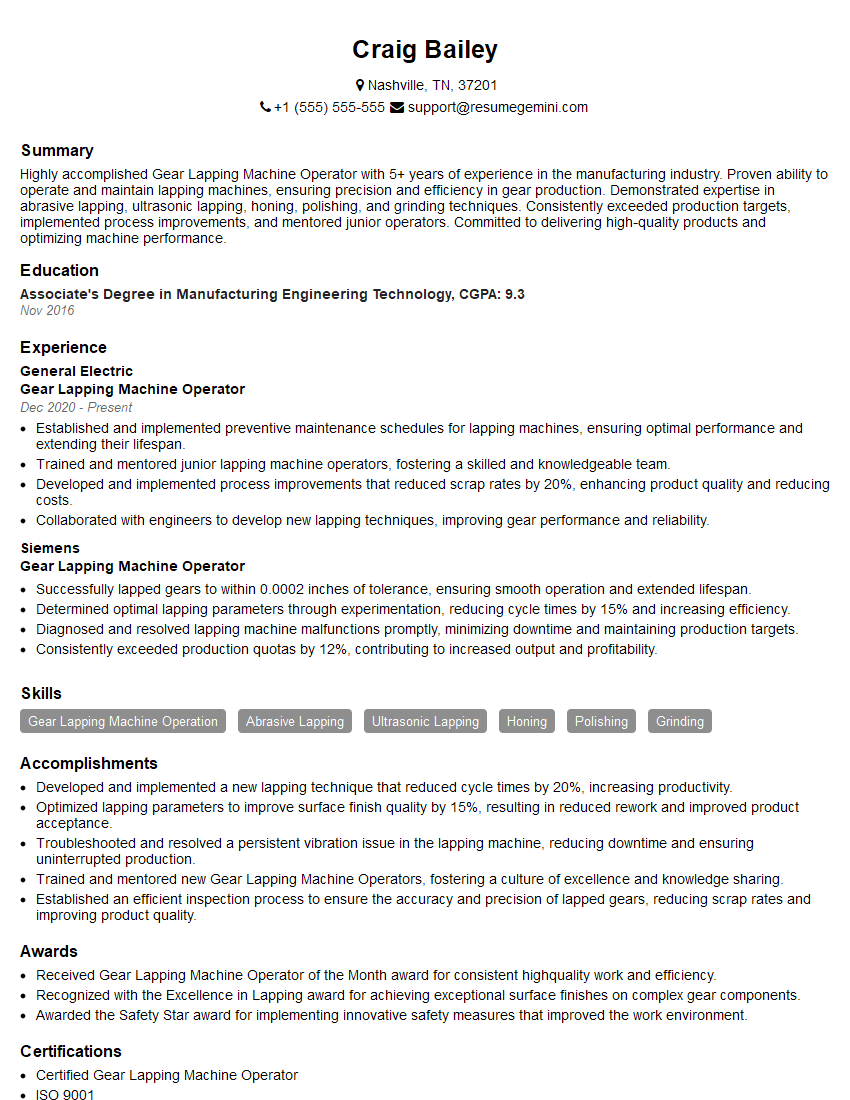

Craig Bailey

Gear Lapping Machine Operator

Summary

Highly accomplished Gear Lapping Machine Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate and maintain lapping machines, ensuring precision and efficiency in gear production. Demonstrated expertise in abrasive lapping, ultrasonic lapping, honing, polishing, and grinding techniques. Consistently exceeded production targets, implemented process improvements, and mentored junior operators. Committed to delivering high-quality products and optimizing machine performance.

Education

Associate’s Degree in Manufacturing Engineering Technology

November 2016

Skills

- Gear Lapping Machine Operation

- Abrasive Lapping

- Ultrasonic Lapping

- Honing

- Polishing

- Grinding

Work Experience

Gear Lapping Machine Operator

- Established and implemented preventive maintenance schedules for lapping machines, ensuring optimal performance and extending their lifespan.

- Trained and mentored junior lapping machine operators, fostering a skilled and knowledgeable team.

- Developed and implemented process improvements that reduced scrap rates by 20%, enhancing product quality and reducing costs.

- Collaborated with engineers to develop new lapping techniques, improving gear performance and reliability.

Gear Lapping Machine Operator

- Successfully lapped gears to within 0.0002 inches of tolerance, ensuring smooth operation and extended lifespan.

- Determined optimal lapping parameters through experimentation, reducing cycle times by 15% and increasing efficiency.

- Diagnosed and resolved lapping machine malfunctions promptly, minimizing downtime and maintaining production targets.

- Consistently exceeded production quotas by 12%, contributing to increased output and profitability.

Accomplishments

- Developed and implemented a new lapping technique that reduced cycle times by 20%, increasing productivity.

- Optimized lapping parameters to improve surface finish quality by 15%, resulting in reduced rework and improved product acceptance.

- Troubleshooted and resolved a persistent vibration issue in the lapping machine, reducing downtime and ensuring uninterrupted production.

- Trained and mentored new Gear Lapping Machine Operators, fostering a culture of excellence and knowledge sharing.

- Established an efficient inspection process to ensure the accuracy and precision of lapped gears, reducing scrap rates and improving product quality.

Awards

- Received Gear Lapping Machine Operator of the Month award for consistent highquality work and efficiency.

- Recognized with the Excellence in Lapping award for achieving exceptional surface finishes on complex gear components.

- Awarded the Safety Star award for implementing innovative safety measures that improved the work environment.

Certificates

- Certified Gear Lapping Machine Operator

- ISO 9001

- ASME B47.1

- ANSI/AGMA 1

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Lapping Machine Operator

- Highlight your experience and expertise in gear lapping techniques, including abrasive lapping, ultrasonic lapping, honing, polishing, and grinding.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on production efficiency and quality.

- Showcase your problem-solving abilities and proactive approach to machine maintenance.

- Emphasize your commitment to safety and adherence to industry standards and best practices.

- Consider obtaining relevant certifications, such as the Certified Gear Lapping Machine Operator (CGLMO) from the American Gear Manufacturers Association (AGMA), to enhance your credibility.

Essential Experience Highlights for a Strong Gear Lapping Machine Operator Resume

- Operate gear lapping machines to achieve precise tolerances within 0.0002 inches.

- Determine optimal lapping parameters to minimize cycle times and maximize efficiency.

- Diagnose and resolve machine malfunctions promptly to maintain production schedules.

- Establish and implement preventive maintenance plans to ensure optimal machine performance.

- Train and supervise junior lapping machine operators to develop a skilled workforce.

- Collaborate with engineers to improve lapping techniques and enhance gear quality.

- Monitor production processes and implement continuous improvement initiatives.

Frequently Asked Questions (FAQ’s) For Gear Lapping Machine Operator

What is gear lapping?

Gear lapping is a precision machining process used to refine the surface finish and geometry of gears. It involves rotating the gear against a lapping tool with an abrasive compound to remove microscopic imperfections and achieve the desired surface quality.

What are the different types of gear lapping machines?

There are various types of gear lapping machines, including horizontal, vertical, and planetary machines. Each type is designed for specific gear sizes and applications.

What are the key skills required for a Gear Lapping Machine Operator?

Key skills for a Gear Lapping Machine Operator include proficiency in gear lapping techniques, machine operation and maintenance, quality control, and adherence to industry standards.

What are the career advancement opportunities for a Gear Lapping Machine Operator?

With experience and additional training, Gear Lapping Machine Operators can advance to roles such as Quality Inspector, Production Supervisor, or Manufacturing Engineer.

What are the safety precautions to consider when operating a gear lapping machine?

Important safety precautions include wearing appropriate safety gear, following proper machine operation procedures, and maintaining a clean and organized work area.