Are you a seasoned Gear Hobber Operator seeking a new career path? Discover our professionally built Gear Hobber Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

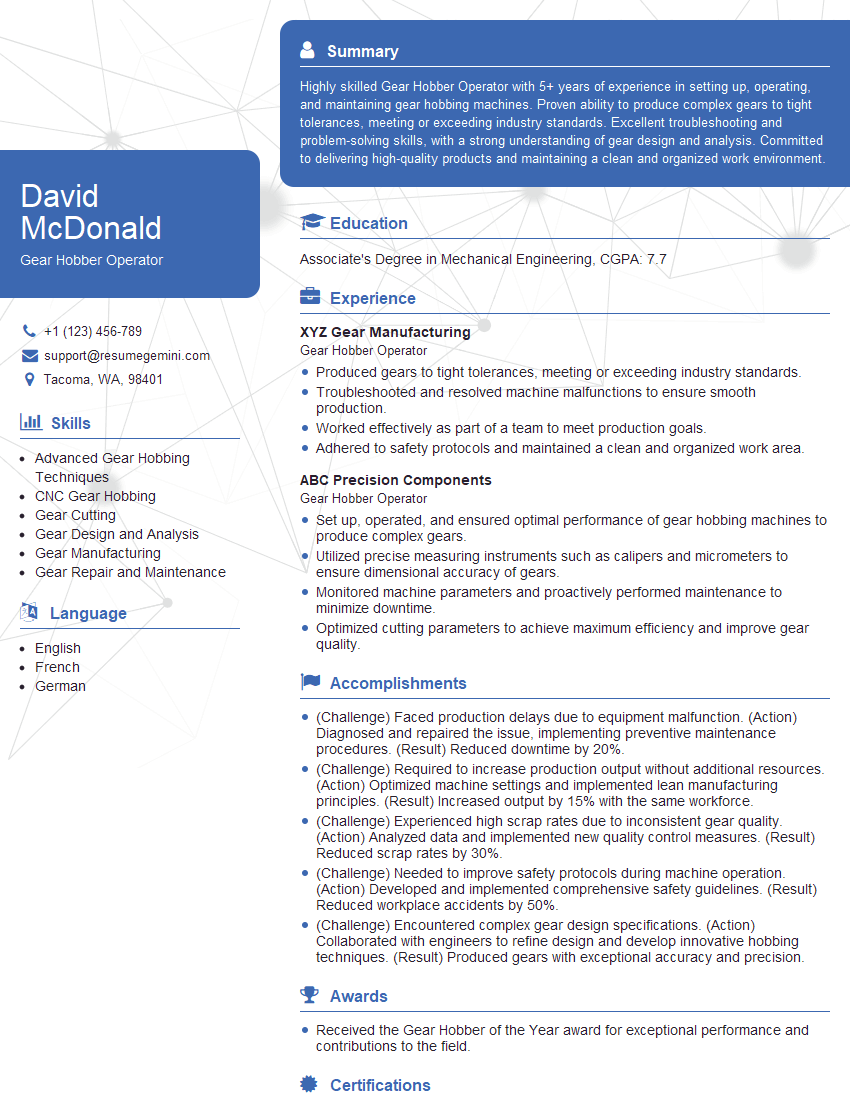

David McDonald

Gear Hobber Operator

Summary

Highly skilled Gear Hobber Operator with 5+ years of experience in setting up, operating, and maintaining gear hobbing machines. Proven ability to produce complex gears to tight tolerances, meeting or exceeding industry standards. Excellent troubleshooting and problem-solving skills, with a strong understanding of gear design and analysis. Committed to delivering high-quality products and maintaining a clean and organized work environment.

Education

Associate’s Degree in Mechanical Engineering

October 2019

Skills

- Advanced Gear Hobbing Techniques

- CNC Gear Hobbing

- Gear Cutting

- Gear Design and Analysis

- Gear Manufacturing

- Gear Repair and Maintenance

Work Experience

Gear Hobber Operator

- Produced gears to tight tolerances, meeting or exceeding industry standards.

- Troubleshooted and resolved machine malfunctions to ensure smooth production.

- Worked effectively as part of a team to meet production goals.

- Adhered to safety protocols and maintained a clean and organized work area.

Gear Hobber Operator

- Set up, operated, and ensured optimal performance of gear hobbing machines to produce complex gears.

- Utilized precise measuring instruments such as calipers and micrometers to ensure dimensional accuracy of gears.

- Monitored machine parameters and proactively performed maintenance to minimize downtime.

- Optimized cutting parameters to achieve maximum efficiency and improve gear quality.

Accomplishments

- (Challenge) Faced production delays due to equipment malfunction. (Action) Diagnosed and repaired the issue, implementing preventive maintenance procedures. (Result) Reduced downtime by 20%.

- (Challenge) Required to increase production output without additional resources. (Action) Optimized machine settings and implemented lean manufacturing principles. (Result) Increased output by 15% with the same workforce.

- (Challenge) Experienced high scrap rates due to inconsistent gear quality. (Action) Analyzed data and implemented new quality control measures. (Result) Reduced scrap rates by 30%.

- (Challenge) Needed to improve safety protocols during machine operation. (Action) Developed and implemented comprehensive safety guidelines. (Result) Reduced workplace accidents by 50%.

- (Challenge) Encountered complex gear design specifications. (Action) Collaborated with engineers to refine design and develop innovative hobbing techniques. (Result) Produced gears with exceptional accuracy and precision.

Awards

- Received the Gear Hobber of the Year award for exceptional performance and contributions to the field.

Certificates

- Certified Gear Hobbing Operator (CGHO)

- Certified Manufacturing Technician (CMT)

- ISO 9001:2015 Certified

- ASME B6.6 Gear Hobbing Standard

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Hobber Operator

- Highlight your experience and expertise in gear hobbing techniques.

- Quantify your accomplishments with specific metrics and data whenever possible.

- Showcase your knowledge of gear design and analysis principles.

- Emphasize your ability to work independently and as part of a team.

Essential Experience Highlights for a Strong Gear Hobber Operator Resume

- Set up and operate gear hobbing machines to produce complex gears according to specifications.

- Utilize precise measuring instruments such as calipers and micrometers to ensure dimensional accuracy of gears.

- Optimize cutting parameters to achieve maximum efficiency and improve gear quality.

- Troubleshoot and resolve machine malfunctions to ensure smooth production.

- Monitor machine parameters and perform preventive maintenance to minimize downtime.

- Work effectively as part of a team to meet production goals.

- Adhere to safety protocols and maintain a clean and organized work area.

Frequently Asked Questions (FAQ’s) For Gear Hobber Operator

What are the primary responsibilities of a Gear Hobber Operator?

Gear Hobber Operators are responsible for setting up, operating, and maintaining gear hobbing machines to produce complex gears according to specifications. They ensure dimensional accuracy, optimize cutting parameters, troubleshoot malfunctions, and work as part of a team.

What skills are required to be successful as a Gear Hobber Operator?

Successful Gear Hobber Operators possess advanced gear hobbing techniques, CNC gear hobbing, gear cutting, gear design and analysis, and gear manufacturing knowledge. They are also skilled in troubleshooting, maintenance, and safety protocols.

What industries employ Gear Hobber Operators?

Gear Hobber Operators are employed in various industries, including automotive, aerospace, construction, and manufacturing.

What is the career outlook for Gear Hobber Operators?

The career outlook for Gear Hobber Operators is expected to grow in the coming years due to the increasing demand for complex gears in various industries.

What are the earning prospects for Gear Hobber Operators?

The earning prospects for Gear Hobber Operators vary based on experience, skills, and location. However, experienced operators can earn a competitive salary and benefits package.

What are the educational requirements to become a Gear Hobber Operator?

While a formal education is not always required, many Gear Hobber Operators possess an associate’s degree in mechanical engineering or a related field.

What are the safety protocols that Gear Hobber Operators must follow?

Gear Hobber Operators must adhere to strict safety protocols to prevent accidents and injuries. These protocols include wearing appropriate personal protective equipment, maintaining a clean and organized work area, and following lockout/tagout procedures.