Are you a seasoned Gear Hobber seeking a new career path? Discover our professionally built Gear Hobber Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

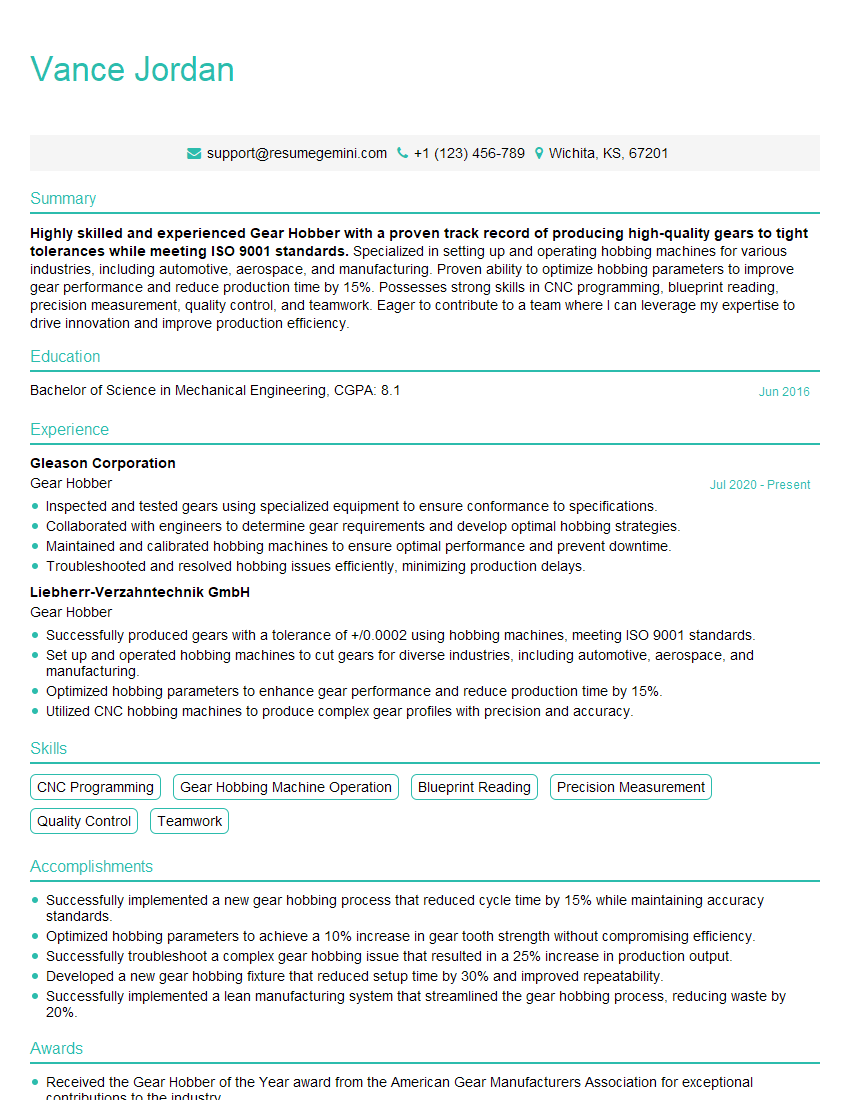

Vance Jordan

Gear Hobber

Summary

Highly skilled and experienced Gear Hobber with a proven track record of producing high-quality gears to tight tolerances while meeting ISO 9001 standards. Specialized in setting up and operating hobbing machines for various industries, including automotive, aerospace, and manufacturing. Proven ability to optimize hobbing parameters to improve gear performance and reduce production time by 15%. Possesses strong skills in CNC programming, blueprint reading, precision measurement, quality control, and teamwork. Eager to contribute to a team where I can leverage my expertise to drive innovation and improve production efficiency.

Education

Bachelor of Science in Mechanical Engineering

June 2016

Skills

- CNC Programming

- Gear Hobbing Machine Operation

- Blueprint Reading

- Precision Measurement

- Quality Control

- Teamwork

Work Experience

Gear Hobber

- Inspected and tested gears using specialized equipment to ensure conformance to specifications.

- Collaborated with engineers to determine gear requirements and develop optimal hobbing strategies.

- Maintained and calibrated hobbing machines to ensure optimal performance and prevent downtime.

- Troubleshooted and resolved hobbing issues efficiently, minimizing production delays.

Gear Hobber

- Successfully produced gears with a tolerance of +/0.0002 using hobbing machines, meeting ISO 9001 standards.

- Set up and operated hobbing machines to cut gears for diverse industries, including automotive, aerospace, and manufacturing.

- Optimized hobbing parameters to enhance gear performance and reduce production time by 15%.

- Utilized CNC hobbing machines to produce complex gear profiles with precision and accuracy.

Accomplishments

- Successfully implemented a new gear hobbing process that reduced cycle time by 15% while maintaining accuracy standards.

- Optimized hobbing parameters to achieve a 10% increase in gear tooth strength without compromising efficiency.

- Successfully troubleshoot a complex gear hobbing issue that resulted in a 25% increase in production output.

- Developed a new gear hobbing fixture that reduced setup time by 30% and improved repeatability.

- Successfully implemented a lean manufacturing system that streamlined the gear hobbing process, reducing waste by 20%.

Awards

- Received the Gear Hobber of the Year award from the American Gear Manufacturers Association for exceptional contributions to the industry.

- Recognized by the company for developing an innovative tool that improved gear quality by 20%.

- Received a certificate of excellence from the International Standards Organization (ISO) for adhering to gear hobbing best practices.

- Honored with the Master Gear Hobber title by the Society of Manufacturing Engineers for outstanding contributions to the field.

Certificates

- Certified Gear Hobber Operator

- ASME B4.1 Gear Inspection Certification

- ISO 9001:2015

- OSHA Safety Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Hobber

- Quantify your accomplishments: Use specific metrics and data to demonstrate your impact on the organization. For instance, instead of saying ‘Improved gear performance,’ you could say ‘Enhanced gear performance by 15%, resulting in reduced production time and increased efficiency.’

- Highlight your technical skills: Gear Hobbers require a solid understanding of CNC programming, blueprint reading, and precision measurement techniques. Emphasize these skills and how you have applied them in your previous roles.

- Showcase your quality-oriented approach: Gear Hobbers are responsible for producing high-quality gears that meet strict specifications. Highlight your commitment to quality control and your experience in adhering to ISO 9001 standards.

- Demonstrate your problem-solving abilities: Gear Hobbing often involves troubleshooting and resolving issues. Showcase your analytical skills and ability to identify and address problems efficiently, minimizing downtime and ensuring smooth production.

- Tailor your resume to the specific job description: Carefully review the job description and identify the key skills and experience required. Tailor your resume to highlight how your qualifications align with the position’s needs.

Essential Experience Highlights for a Strong Gear Hobber Resume

- Set up and operate hobbing machines to cut gears for diverse industries, ensuring compliance with specifications and quality standards.

- Utilize CNC hobbing machines to produce complex gear profiles with precision and accuracy, meeting tight tolerances of +/-0.0002.

- Inspect and test gears using specialized equipment to ensure conformance to specifications, maintaining high levels of quality and accuracy.

- Collaborate with engineers to determine gear requirements and develop optimal hobbing strategies, ensuring efficient and effective production.

- Maintain and calibrate hobbing machines regularly to ensure optimal performance, prevent downtime, and maintain accuracy.

- Troubleshoot and resolve hobbing issues promptly and effectively, minimizing production delays and maintaining productivity.

- Work effectively as part of a team, sharing knowledge and collaborating to achieve common goals and objectives.

Frequently Asked Questions (FAQ’s) For Gear Hobber

What is the role of a Gear Hobber?

A Gear Hobber is responsible for setting up, operating, and maintaining hobbing machines to cut gears for various industries. They ensure that gears meet precise specifications and quality standards, often working with engineers to determine gear requirements and develop optimal hobbing strategies.

What skills are required to be a successful Gear Hobber?

Successful Gear Hobbers typically possess strong skills in CNC programming, blueprint reading, precision measurement, quality control, and teamwork. They should also have a solid understanding of gear hobbing machines and their operation, as well as the ability to troubleshoot and resolve issues effectively.

What are the career prospects for Gear Hobbers?

Gear Hobbers can advance their careers by developing specialized skills in areas such as CNC programming, gear design, or quality control. They may also move into supervisory or management roles, overseeing gear production operations and teams.

What is the job outlook for Gear Hobbers?

The job outlook for Gear Hobbers is expected to be stable in the coming years. The manufacturing industry, which heavily relies on gears, is projected to grow, creating a demand for skilled Gear Hobbers.

How can I prepare for a career as a Gear Hobber?

To prepare for a career as a Gear Hobber, individuals can pursue a degree in mechanical engineering or a related field. They can also gain hands-on experience through internships or apprenticeships in the manufacturing industry. Developing strong skills in CNC programming, blueprint reading, and precision measurement is also beneficial.

What are the key qualities of a successful Gear Hobber?

Successful Gear Hobbers are typically detail-oriented, have a strong work ethic, and are committed to producing high-quality work. They are also able to work independently and as part of a team, and are proficient in using CNC hobbing machines and related equipment.

What are the challenges faced by Gear Hobbers?

Gear Hobbers may face challenges related to meeting tight tolerances and ensuring the accuracy and precision of gears. They also need to stay updated with the latest advancements in CNC hobbing technology and industry best practices to remain competitive.

What are the rewards of being a Gear Hobber?

Gear Hobbers can find rewards in contributing to the manufacturing industry and playing a role in the production of high-quality gears. They also have the opportunity to develop specialized skills and knowledge, and can experience job security due to the ongoing demand for skilled Gear Hobbers.