Are you a seasoned Gear Machine Operator seeking a new career path? Discover our professionally built Gear Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

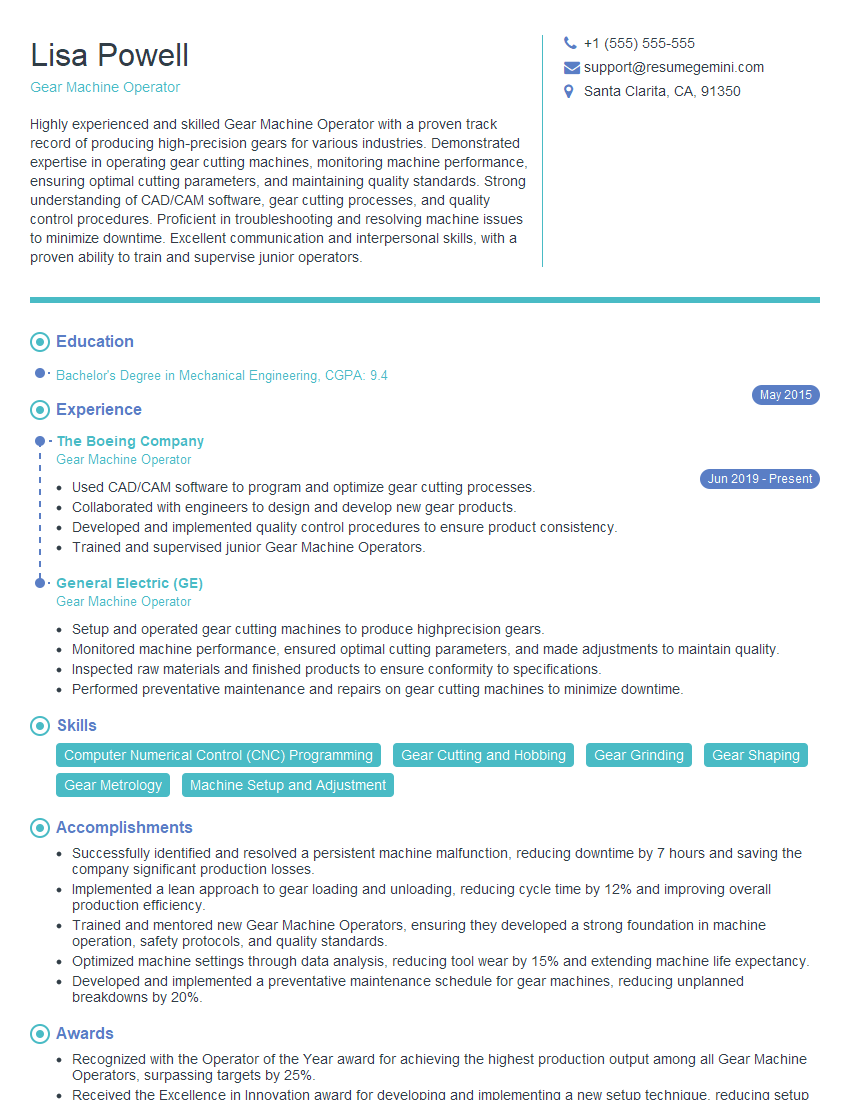

Lisa Powell

Gear Machine Operator

Summary

Highly experienced and skilled Gear Machine Operator with a proven track record of producing high-precision gears for various industries. Demonstrated expertise in operating gear cutting machines, monitoring machine performance, ensuring optimal cutting parameters, and maintaining quality standards. Strong understanding of CAD/CAM software, gear cutting processes, and quality control procedures. Proficient in troubleshooting and resolving machine issues to minimize downtime. Excellent communication and interpersonal skills, with a proven ability to train and supervise junior operators.

Education

Bachelor’s Degree in Mechanical Engineering

May 2015

Skills

- Computer Numerical Control (CNC) Programming

- Gear Cutting and Hobbing

- Gear Grinding

- Gear Shaping

- Gear Metrology

- Machine Setup and Adjustment

Work Experience

Gear Machine Operator

- Used CAD/CAM software to program and optimize gear cutting processes.

- Collaborated with engineers to design and develop new gear products.

- Developed and implemented quality control procedures to ensure product consistency.

- Trained and supervised junior Gear Machine Operators.

Gear Machine Operator

- Setup and operated gear cutting machines to produce highprecision gears.

- Monitored machine performance, ensured optimal cutting parameters, and made adjustments to maintain quality.

- Inspected raw materials and finished products to ensure conformity to specifications.

- Performed preventative maintenance and repairs on gear cutting machines to minimize downtime.

Accomplishments

- Successfully identified and resolved a persistent machine malfunction, reducing downtime by 7 hours and saving the company significant production losses.

- Implemented a lean approach to gear loading and unloading, reducing cycle time by 12% and improving overall production efficiency.

- Trained and mentored new Gear Machine Operators, ensuring they developed a strong foundation in machine operation, safety protocols, and quality standards.

- Optimized machine settings through data analysis, reducing tool wear by 15% and extending machine life expectancy.

- Developed and implemented a preventative maintenance schedule for gear machines, reducing unplanned breakdowns by 20%.

Awards

- Recognized with the Operator of the Year award for achieving the highest production output among all Gear Machine Operators, surpassing targets by 25%.

- Received the Excellence in Innovation award for developing and implementing a new setup technique, reducing setup time by 18% and improving machine efficiency.

- Presented with the Safety Champion award for maintaining an impeccable safety record and proactively implementing safety measures, ensuring a hazardfree work environment.

- Honored with the Teamwork Award for actively collaborating with colleagues to overcome production challenges, exceeding performance goals.

Certificates

- CNC Programming Certification

- Gear Manufacturing Certification

- ISO 9001 Quality Management Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Gear Machine Operator

- Highlight your experience and expertise in operating gear cutting machines and producing high-quality gears.

- Quantify your accomplishments whenever possible, using specific metrics to demonstrate your impact on the company.

- Showcase your knowledge of CAD/CAM software, gear cutting processes, and quality control procedures.

- Emphasize your ability to troubleshoot and resolve machine issues, as well as your training and supervisory skills.

Essential Experience Highlights for a Strong Gear Machine Operator Resume

- Set up and operated gear cutting machines to produce high-precision gears.

- Monitored machine performance, ensured optimal cutting parameters, and made adjustments to maintain quality.

- Inspected raw materials and finished products to ensure conformity to specifications.

- Performed preventative maintenance and repairs on gear cutting machines to minimize downtime.

- Used CAD/CAM software to program and optimize gear cutting processes.

- Collaborated with engineers to design and develop new gear products.

Frequently Asked Questions (FAQ’s) For Gear Machine Operator

What are the primary responsibilities of a Gear Machine Operator?

Gear Machine Operators are responsible for setting up and operating gear cutting machines to produce high-precision gears. They monitor machine performance, ensure optimal cutting parameters, inspect raw materials and finished products, perform preventative maintenance and repairs, and use CAD/CAM software to program and optimize gear cutting processes.

What skills are required to be a successful Gear Machine Operator?

Successful Gear Machine Operators typically have a strong understanding of gear cutting processes, machine setup and adjustment, CNC programming, gear metrology, and quality control procedures. They are also proficient in troubleshooting and resolving machine issues, and have excellent communication and interpersonal skills.

What is the work environment like for a Gear Machine Operator?

Gear Machine Operators typically work in manufacturing facilities, operating gear cutting machines in a fast-paced and demanding environment. They may work independently or as part of a team, and may be required to work overtime or on weekends to meet production deadlines.

What are the career prospects for a Gear Machine Operator?

Gear Machine Operators with experience and expertise can advance to supervisory or management positions, or specialize in specific areas such as gear design or quality control. They may also pursue further education to enhance their skills and knowledge.

What is the average salary for a Gear Machine Operator?

The average salary for a Gear Machine Operator in the United States is around $50,000 per year, according to Indeed. Salaries may vary depending on experience, location, and industry.

What are the benefits of working as a Gear Machine Operator?

Benefits of working as a Gear Machine Operator include job stability, competitive salaries, opportunities for advancement, and the satisfaction of working in a skilled trade.