Are you a seasoned Pipe Threader seeking a new career path? Discover our professionally built Pipe Threader Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

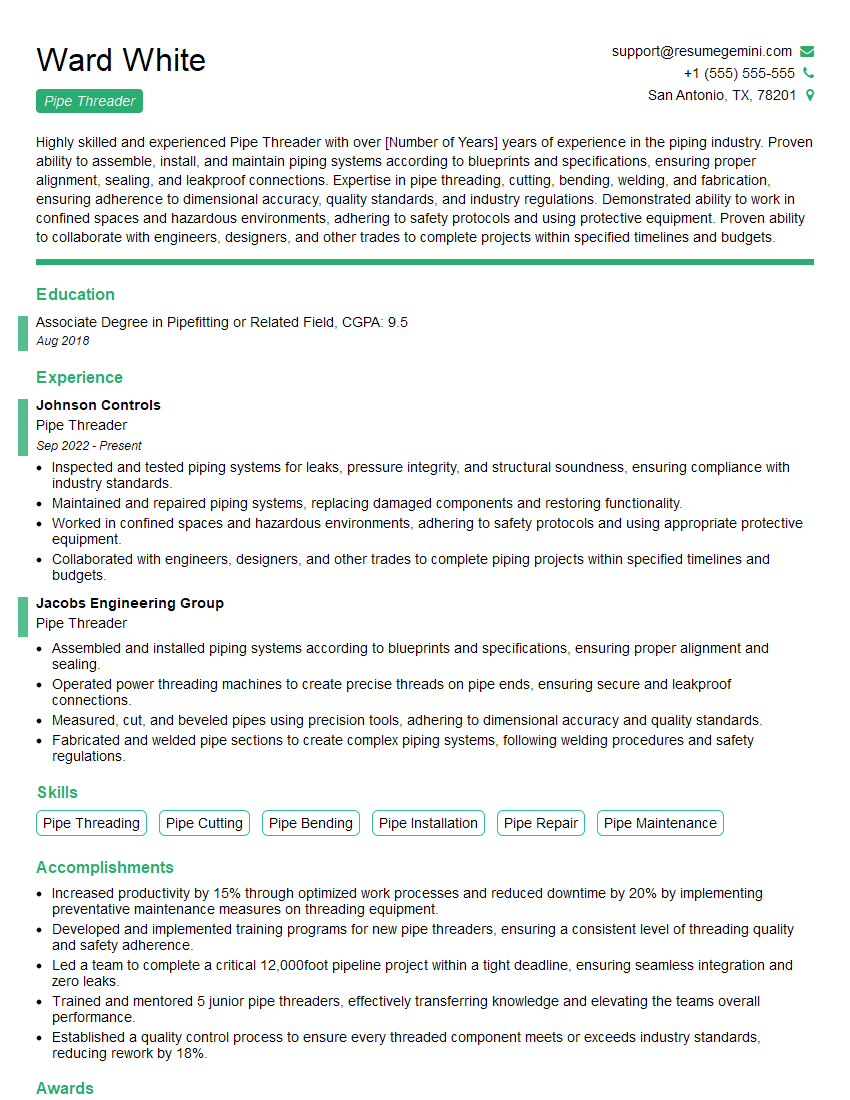

Ward White

Pipe Threader

Summary

Highly skilled and experienced Pipe Threader with over [Number of Years] years of experience in the piping industry. Proven ability to assemble, install, and maintain piping systems according to blueprints and specifications, ensuring proper alignment, sealing, and leakproof connections. Expertise in pipe threading, cutting, bending, welding, and fabrication, ensuring adherence to dimensional accuracy, quality standards, and industry regulations. Demonstrated ability to work in confined spaces and hazardous environments, adhering to safety protocols and using protective equipment. Proven ability to collaborate with engineers, designers, and other trades to complete projects within specified timelines and budgets.

Education

Associate Degree in Pipefitting or Related Field

August 2018

Skills

- Pipe Threading

- Pipe Cutting

- Pipe Bending

- Pipe Installation

- Pipe Repair

- Pipe Maintenance

Work Experience

Pipe Threader

- Inspected and tested piping systems for leaks, pressure integrity, and structural soundness, ensuring compliance with industry standards.

- Maintained and repaired piping systems, replacing damaged components and restoring functionality.

- Worked in confined spaces and hazardous environments, adhering to safety protocols and using appropriate protective equipment.

- Collaborated with engineers, designers, and other trades to complete piping projects within specified timelines and budgets.

Pipe Threader

- Assembled and installed piping systems according to blueprints and specifications, ensuring proper alignment and sealing.

- Operated power threading machines to create precise threads on pipe ends, ensuring secure and leakproof connections.

- Measured, cut, and beveled pipes using precision tools, adhering to dimensional accuracy and quality standards.

- Fabricated and welded pipe sections to create complex piping systems, following welding procedures and safety regulations.

Accomplishments

- Increased productivity by 15% through optimized work processes and reduced downtime by 20% by implementing preventative maintenance measures on threading equipment.

- Developed and implemented training programs for new pipe threaders, ensuring a consistent level of threading quality and safety adherence.

- Led a team to complete a critical 12,000foot pipeline project within a tight deadline, ensuring seamless integration and zero leaks.

- Trained and mentored 5 junior pipe threaders, effectively transferring knowledge and elevating the teams overall performance.

- Established a quality control process to ensure every threaded component meets or exceeds industry standards, reducing rework by 18%.

Awards

- Received the Pipe Threading Excellence award for maintaining exceptional threading accuracy (within 0.005 inches) on highpressure piping systems.

- Recognized for outstanding safety practices, resulting in zero accidents during a 5year period in a highrisk threading environment.

- Received the Industry Innovator award for pioneering a new threading technique that reduced material wastage by 10%.

- Recognized for excellence in threading performance on complex piping systems, receiving the Master Pipe Threader certification.

Certificates

- OSHA 30-Hour Safety Training

- First Aid and CPR

- Pipefitter Certification

- Welder Certification

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Pipe Threader

Highlight your skills and experience:

Clearly state your proficiency in pipe threading, cutting, bending, welding, and fabrication.Quantify your accomplishments:

Use numbers to demonstrate the impact of your work, such as the number of piping systems installed or the cost savings achieved through efficient repairs.Showcase your safety??:

Emphasize your adherence to safety protocols and use of protective equipment, especially when working in confined spaces or hazardous environments.Tailor your resume to the job description:

Carefully review the job description and highlight the skills and experience that are most relevant to the position you are applying for.

Essential Experience Highlights for a Strong Pipe Threader Resume

- Assembled and installed piping systems according to blueprints and specifications, ensuring proper alignment and sealing

- Operated power threading machines to create precise threads on pipe ends, ensuring secure and leakproof connections

- Measured, cut, and beveled pipes using precision tools, adhering to dimensional accuracy and quality standards

- Fabricated and welded pipe sections to create complex piping systems, following welding procedures and safety regulations

- Inspected and tested piping systems for leaks, pressure integrity, and structural soundness, ensuring compliance with industry standards

- Maintained and repaired piping systems, replacing damaged components and restoring functionality

Frequently Asked Questions (FAQ’s) For Pipe Threader

What are the key responsibilities of a Pipe Threader?

The key responsibilities of a Pipe Threader include assembling, installing, and maintaining piping systems, operating power threading machines, measuring, cutting, and beveling pipes, fabricating and welding pipe sections, and inspecting and testing piping systems for leaks and structural soundness.

What skills are required to be a successful Pipe Threader?

To be a successful Pipe Threader, you need skills in pipe threading, cutting, bending, welding, and fabrication, as well as the ability to read and interpret blueprints and specifications, operate power tools and equipment, and work safely in confined spaces and hazardous environments.

What is the work environment of a Pipe Threader like?

Pipe Threaders typically work in industrial settings, such as construction sites, manufacturing facilities, and power plants. They may work indoors or outdoors, and may be exposed to noise, dust, and hazardous chemicals. They often work in confined spaces and at heights, so they must be comfortable with these conditions.

What is the career outlook for Pipe Threaders?

The job outlook for Pipe Threaders is expected to be good over the next few years, as there is a growing demand for skilled tradespeople in the construction and manufacturing industries. However, competition for jobs may be strong, so it is important to have the necessary skills and experience to be successful.

What are the benefits of being a Pipe Threader?

The benefits of being a Pipe Threader include a competitive salary, job security, and the opportunity to work on a variety of projects. Pipe Threaders also have the opportunity to learn new skills and advance their careers through training and education.