Are you a seasoned Rim Turning Machine Operator seeking a new career path? Discover our professionally built Rim Turning Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

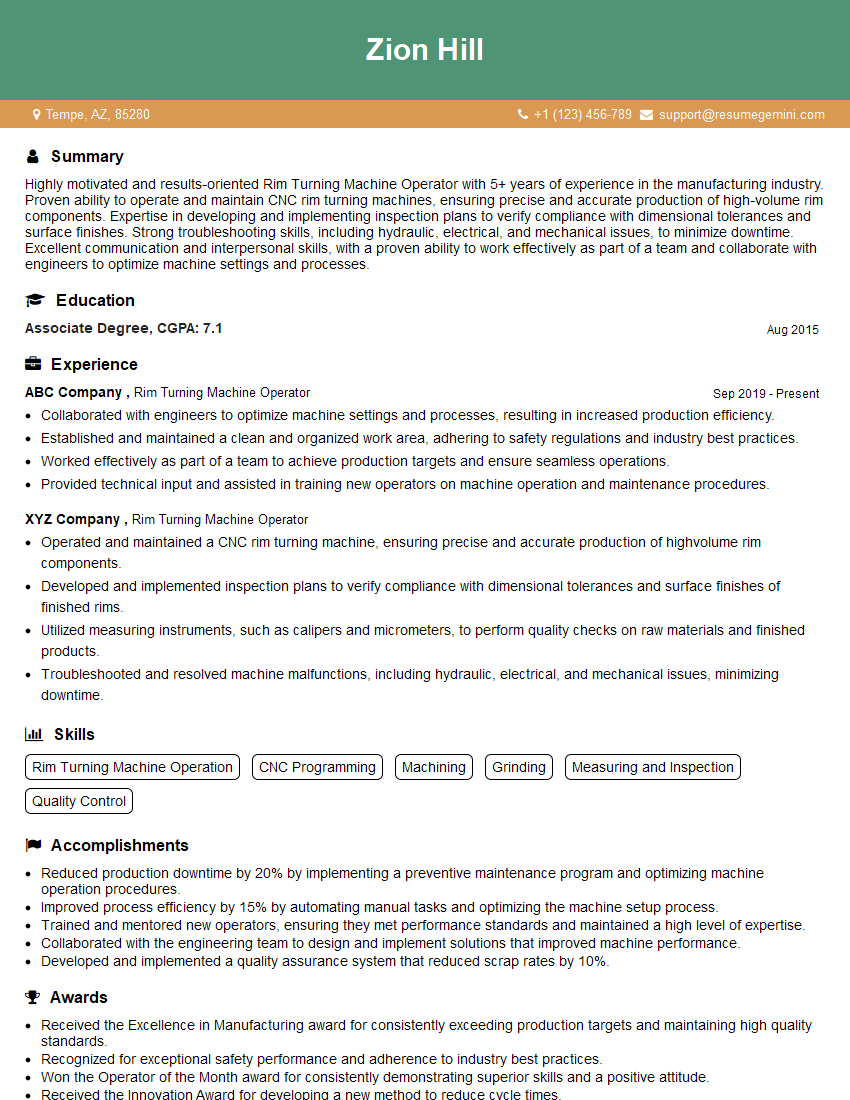

Zion Hill

Rim Turning Machine Operator

Summary

Highly motivated and results-oriented Rim Turning Machine Operator with 5+ years of experience in the manufacturing industry. Proven ability to operate and maintain CNC rim turning machines, ensuring precise and accurate production of high-volume rim components. Expertise in developing and implementing inspection plans to verify compliance with dimensional tolerances and surface finishes. Strong troubleshooting skills, including hydraulic, electrical, and mechanical issues, to minimize downtime. Excellent communication and interpersonal skills, with a proven ability to work effectively as part of a team and collaborate with engineers to optimize machine settings and processes.

Education

Associate Degree

August 2015

Skills

- Rim Turning Machine Operation

- CNC Programming

- Machining

- Grinding

- Measuring and Inspection

- Quality Control

Work Experience

Rim Turning Machine Operator

- Collaborated with engineers to optimize machine settings and processes, resulting in increased production efficiency.

- Established and maintained a clean and organized work area, adhering to safety regulations and industry best practices.

- Worked effectively as part of a team to achieve production targets and ensure seamless operations.

- Provided technical input and assisted in training new operators on machine operation and maintenance procedures.

Rim Turning Machine Operator

- Operated and maintained a CNC rim turning machine, ensuring precise and accurate production of highvolume rim components.

- Developed and implemented inspection plans to verify compliance with dimensional tolerances and surface finishes of finished rims.

- Utilized measuring instruments, such as calipers and micrometers, to perform quality checks on raw materials and finished products.

- Troubleshooted and resolved machine malfunctions, including hydraulic, electrical, and mechanical issues, minimizing downtime.

Accomplishments

- Reduced production downtime by 20% by implementing a preventive maintenance program and optimizing machine operation procedures.

- Improved process efficiency by 15% by automating manual tasks and optimizing the machine setup process.

- Trained and mentored new operators, ensuring they met performance standards and maintained a high level of expertise.

- Collaborated with the engineering team to design and implement solutions that improved machine performance.

- Developed and implemented a quality assurance system that reduced scrap rates by 10%.

Awards

- Received the Excellence in Manufacturing award for consistently exceeding production targets and maintaining high quality standards.

- Recognized for exceptional safety performance and adherence to industry best practices.

- Won the Operator of the Month award for consistently demonstrating superior skills and a positive attitude.

- Received the Innovation Award for developing a new method to reduce cycle times.

Certificates

- Certified Manufacturing Technologist (CMfgT)

- Certified Production Technician (CPT)

- Certified Quality Engineer (CQE)

- Certified Manufacturing Engineer (CMfgE)

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Rim Turning Machine Operator

Highlight your technical skills and experience.

Make sure to list all of the relevant skills you have, such as CNC programming, machining, grinding, measuring and inspection, and quality control.Showcase your problem-solving abilities.

Employers are looking for candidates who can solve problems and minimize downtime. Be sure to highlight your troubleshooting skills and experience.Emphasize your safety record.

Safety is a top priority in manufacturing environments. Make sure to mention your commitment to safety and your clean and organized work area.Get certified.

There are a number of certifications available for rim turning machine operators. Getting certified can show employers that you are serious about your career and that you have the skills and knowledge to succeed.

Essential Experience Highlights for a Strong Rim Turning Machine Operator Resume

- Operate and maintain CNC rim turning machines to produce high-volume rim components with precision and accuracy

- Develop and implement inspection plans to ensure compliance with dimensional tolerances and surface finishes

- Utilize measuring instruments, such as calipers and micrometers, to perform quality checks on raw materials and finished products

- Troubleshoot and resolve machine malfunctions, including hydraulic, electrical, and mechanical issues, to minimize downtime

- Collaborate with engineers to optimize machine settings and processes, resulting in increased production efficiency

- Establish and maintain a clean and organized work area, adhering to safety regulations and industry best practices

- Provide technical input and assist in training new operators on machine operation and maintenance procedures

Frequently Asked Questions (FAQ’s) For Rim Turning Machine Operator

What is a rim turning machine?

A rim turning machine is a machine that is used to turn the rims of wheels. It is a type of lathe that is specifically designed for this purpose.

What are the different types of rim turning machines?

There are two main types of rim turning machines: manual and CNC. Manual rim turning machines are operated by hand, while CNC rim turning machines are computer-controlled.

What are the advantages of using a CNC rim turning machine?

CNC rim turning machines offer a number of advantages over manual rim turning machines, including increased accuracy, precision, and productivity.

What are the different types of rims that can be turned on a rim turning machine?

A rim turning machine can be used to turn a variety of different types of rims, including steel rims, aluminum rims, and magnesium rims.

What is the process of turning a rim on a rim turning machine?

The process of turning a rim on a rim turning machine involves a number of steps, including mounting the rim on the machine, setting up the machine, and running the machine.

What are the safety precautions that should be taken when operating a rim turning machine?

There are a number of safety precautions that should be taken when operating a rim turning machine, including wearing appropriate safety gear, following the manufacturer’s instructions, and being aware of the machine’s hazards.

What are the career opportunities for rim turning machine operators?

There are a number of career opportunities for rim turning machine operators, including working in a manufacturing environment, working in a repair shop, and working in a dealership.