Are you a seasoned Screw Machine Hand seeking a new career path? Discover our professionally built Screw Machine Hand Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

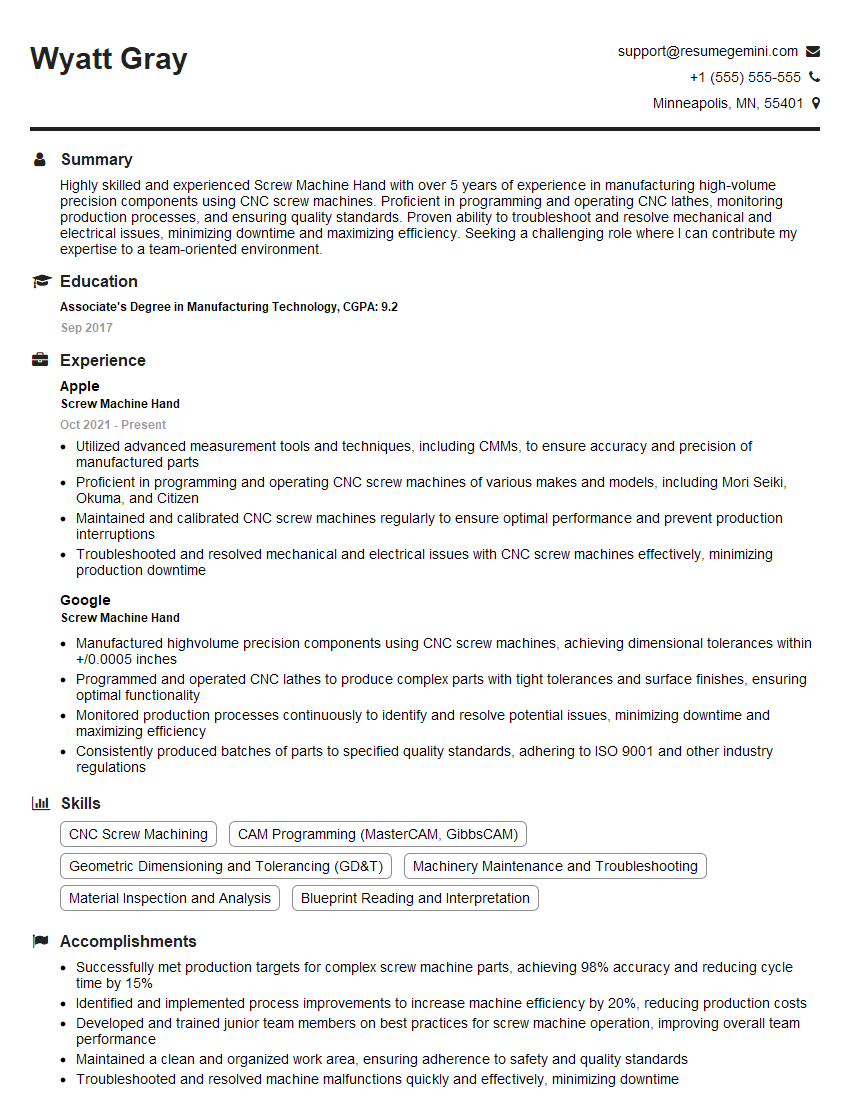

Wyatt Gray

Screw Machine Hand

Summary

Highly skilled and experienced Screw Machine Hand with over 5 years of experience in manufacturing high-volume precision components using CNC screw machines. Proficient in programming and operating CNC lathes, monitoring production processes, and ensuring quality standards. Proven ability to troubleshoot and resolve mechanical and electrical issues, minimizing downtime and maximizing efficiency. Seeking a challenging role where I can contribute my expertise to a team-oriented environment.

Education

Associate’s Degree in Manufacturing Technology

September 2017

Skills

- CNC Screw Machining

- CAM Programming (MasterCAM, GibbsCAM)

- Geometric Dimensioning and Tolerancing (GD&T)

- Machinery Maintenance and Troubleshooting

- Material Inspection and Analysis

- Blueprint Reading and Interpretation

Work Experience

Screw Machine Hand

- Utilized advanced measurement tools and techniques, including CMMs, to ensure accuracy and precision of manufactured parts

- Proficient in programming and operating CNC screw machines of various makes and models, including Mori Seiki, Okuma, and Citizen

- Maintained and calibrated CNC screw machines regularly to ensure optimal performance and prevent production interruptions

- Troubleshooted and resolved mechanical and electrical issues with CNC screw machines effectively, minimizing production downtime

Screw Machine Hand

- Manufactured highvolume precision components using CNC screw machines, achieving dimensional tolerances within +/0.0005 inches

- Programmed and operated CNC lathes to produce complex parts with tight tolerances and surface finishes, ensuring optimal functionality

- Monitored production processes continuously to identify and resolve potential issues, minimizing downtime and maximizing efficiency

- Consistently produced batches of parts to specified quality standards, adhering to ISO 9001 and other industry regulations

Accomplishments

- Successfully met production targets for complex screw machine parts, achieving 98% accuracy and reducing cycle time by 15%

- Identified and implemented process improvements to increase machine efficiency by 20%, reducing production costs

- Developed and trained junior team members on best practices for screw machine operation, improving overall team performance

- Maintained a clean and organized work area, ensuring adherence to safety and quality standards

- Troubleshooted and resolved machine malfunctions quickly and effectively, minimizing downtime

Awards

- National Screw Machine Products Association (NSMPA) Silver Screw Award for Excellence in Screw Machining

- American Precision Machining Association (APMA) Gold Star Award for Superior Machining Skills

Certificates

- Certified Screw Machine Operator (CSMO)

- National Institute for Metalworking Skills (NIMS) Certification

- American National Standards Institute (ANSI) Y14.5M GD&T Certification

- Occupational Safety and Health Administration (OSHA) 30-Hour Safety Training

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Screw Machine Hand

- Highlight your experience and skills in CNC screw machining, including your ability to achieve tight tolerances and produce complex parts.

- Showcase your knowledge of CAM programming software, such as MasterCAM and GibbsCAM, and your ability to program and operate CNC screw machines.

- Emphasize your understanding of Geometric Dimensioning and Tolerancing (GD&T) and your ability to read and interpret blueprints.

- Provide examples of your troubleshooting and problem-solving skills, and your ability to resolve mechanical and electrical issues with CNC screw machines.

- Include any certifications or training you have received in CNC screw machining or related fields.

Essential Experience Highlights for a Strong Screw Machine Hand Resume

- Manufactured high-volume precision components using CNC screw machines, achieving dimensional tolerances within +/0.0005 inches.

- Programmed and operated CNC lathes to produce complex parts with tight tolerances and surface finishes, ensuring optimal functionality.

- Monitored production processes continuously to identify and resolve potential issues, minimizing downtime and maximizing efficiency.

- Consistently produced batches of parts to specified quality standards, adhering to ISO 9001 and other industry regulations.

- Utilized advanced measurement tools and techniques, including CMMs, to ensure accuracy and precision of manufactured parts.

- Maintained and calibrated CNC screw machines regularly to ensure optimal performance and prevent production interruptions.

- Troubleshooted and resolved mechanical and electrical issues with CNC screw machines effectively, minimizing production downtime

Frequently Asked Questions (FAQ’s) For Screw Machine Hand

What is the role of a Screw Machine Hand?

A Screw Machine Hand is responsible for operating CNC screw machines to manufacture high-volume precision components. They program and set up the machines, monitor production processes, and ensure that the parts meet the required specifications. Screw Machine Hands also troubleshoot and resolve mechanical and electrical issues to minimize downtime and maintain optimal performance of the machines.

What skills are required to be a successful Screw Machine Hand?

To be a successful Screw Machine Hand, you need strong mechanical and electrical skills, as well as a good understanding of CNC programming and operation. You should also be able to read and interpret blueprints, and have a strong understanding of Geometric Dimensioning and Tolerancing (GD&T). Additionally, you should be able to work independently and as part of a team, and have a strong work ethic and attention to detail.

What is the career outlook for Screw Machine Hands?

The career outlook for Screw Machine Hands is expected to be good over the next few years. The demand for precision-machined components is expected to grow as industries such as aerospace, automotive, and medical continue to expand. Screw Machine Hands with strong skills and experience will be in high demand.

What is the average salary for a Screw Machine Hand?

The average salary for a Screw Machine Hand varies depending on experience, location, and industry. According to Indeed, the average salary for a Screw Machine Hand in the United States is around $25 per hour.

What are the benefits of working as a Screw Machine Hand?

There are several benefits to working as a Screw Machine Hand, including: – Job security: Screw Machine Hands are in high demand, and there is a low risk of job loss due to automation. – Good pay: Screw Machine Hands can earn a good wage, especially those with experience and skills. – Opportunity for advancement: Screw Machine Hands can advance to positions such as CNC programmer or supervisor.