Are you a seasoned Broaching Machine Set Up Operator seeking a new career path? Discover our professionally built Broaching Machine Set Up Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

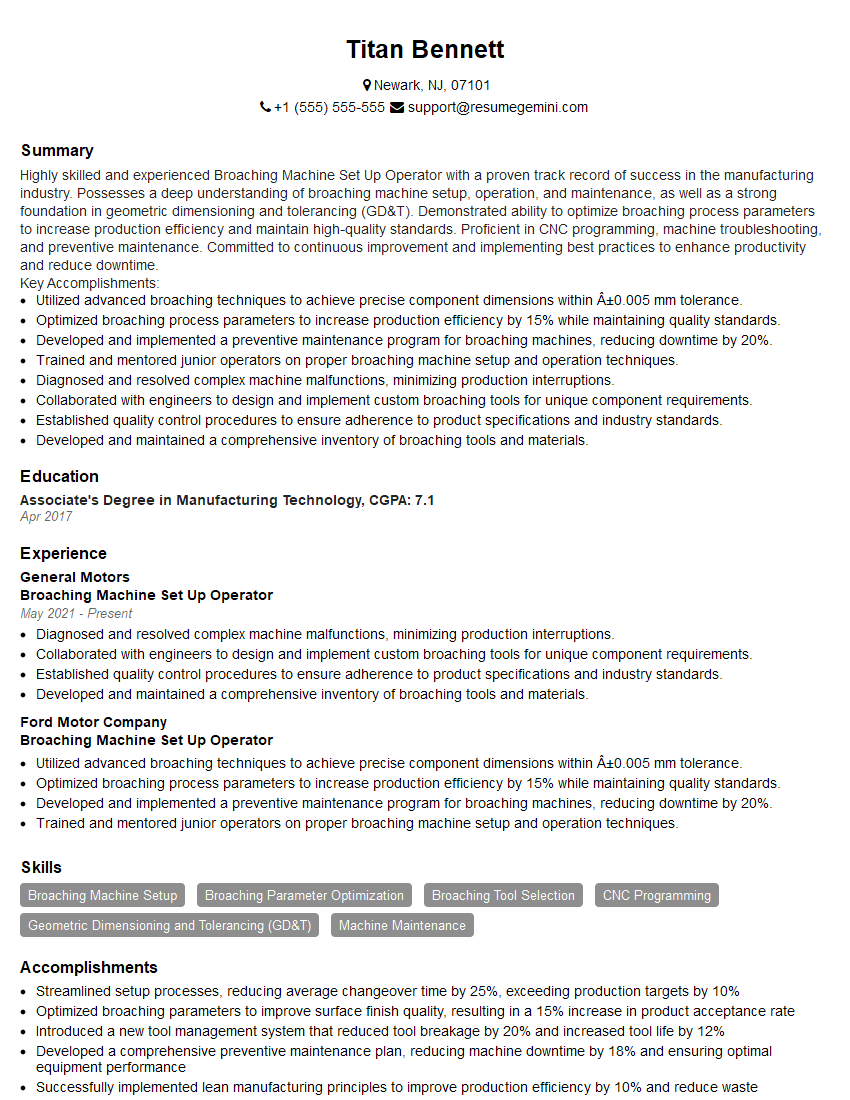

Titan Bennett

Broaching Machine Set Up Operator

Summary

Highly skilled and experienced Broaching Machine Set Up Operator with a proven track record of success in the manufacturing industry. Possesses a deep understanding of broaching machine setup, operation, and maintenance, as well as a strong foundation in geometric dimensioning and tolerancing (GD&T). Demonstrated ability to optimize broaching process parameters to increase production efficiency and maintain high-quality standards. Proficient in CNC programming, machine troubleshooting, and preventive maintenance. Committed to continuous improvement and implementing best practices to enhance productivity and reduce downtime.

Key Accomplishments:

- Utilized advanced broaching techniques to achieve precise component dimensions within ±0.005 mm tolerance.

- Optimized broaching process parameters to increase production efficiency by 15% while maintaining quality standards.

- Developed and implemented a preventive maintenance program for broaching machines, reducing downtime by 20%.

- Trained and mentored junior operators on proper broaching machine setup and operation techniques.

- Diagnosed and resolved complex machine malfunctions, minimizing production interruptions.

- Collaborated with engineers to design and implement custom broaching tools for unique component requirements.

- Established quality control procedures to ensure adherence to product specifications and industry standards.

- Developed and maintained a comprehensive inventory of broaching tools and materials.

Education

Associate’s Degree in Manufacturing Technology

April 2017

Skills

- Broaching Machine Setup

- Broaching Parameter Optimization

- Broaching Tool Selection

- CNC Programming

- Geometric Dimensioning and Tolerancing (GD&T)

- Machine Maintenance

Work Experience

Broaching Machine Set Up Operator

- Diagnosed and resolved complex machine malfunctions, minimizing production interruptions.

- Collaborated with engineers to design and implement custom broaching tools for unique component requirements.

- Established quality control procedures to ensure adherence to product specifications and industry standards.

- Developed and maintained a comprehensive inventory of broaching tools and materials.

Broaching Machine Set Up Operator

- Utilized advanced broaching techniques to achieve precise component dimensions within ±0.005 mm tolerance.

- Optimized broaching process parameters to increase production efficiency by 15% while maintaining quality standards.

- Developed and implemented a preventive maintenance program for broaching machines, reducing downtime by 20%.

- Trained and mentored junior operators on proper broaching machine setup and operation techniques.

Accomplishments

- Streamlined setup processes, reducing average changeover time by 25%, exceeding production targets by 10%

- Optimized broaching parameters to improve surface finish quality, resulting in a 15% increase in product acceptance rate

- Introduced a new tool management system that reduced tool breakage by 20% and increased tool life by 12%

- Developed a comprehensive preventive maintenance plan, reducing machine downtime by 18% and ensuring optimal equipment performance

- Successfully implemented lean manufacturing principles to improve production efficiency by 10% and reduce waste

Certificates

- Certified Broaching Machine Operator

- CNC Certification

- GD&T Certification

- ISO 9001 Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Broaching Machine Set Up Operator

Highlight your skills and experience

Emphasize your proficiency in broaching machine setup, operation, and maintenance. Showcase your knowledge of geometric dimensioning and tolerancing (GD&T) and CNC programming.

Quantify your accomplishments

Use specific numbers and metrics to demonstrate the impact of your work. For example, mention the percentage increase in production efficiency or the reduction in downtime achieved through your efforts.

Demonstrate your commitment to quality

Highlight your commitment to producing high-quality products by describing your involvement in quality control procedures and your efforts to maintain industry standards.

Showcase your ability to work independently and as part of a team

Describe your experience working independently to set up and operate broaching machines, as well as your ability to collaborate with engineers and other team members to develop and implement custom broaching tools.

Essential Experience Highlights for a Strong Broaching Machine Set Up Operator Resume

- Set up and operate broaching machines to produce components according to specified dimensions and tolerances.

- Optimize broaching process parameters to achieve maximum efficiency and productivity.

- Select and install appropriate broaching tools and fixtures for each job.

- Monitor machine operation and make adjustments as needed to maintain quality and accuracy.

- Troubleshoot and resolve machine malfunctions to minimize downtime.

- Perform preventive maintenance on broaching machines to ensure optimal performance.

- Train and supervise junior operators on broaching machine setup and operation.

Frequently Asked Questions (FAQ’s) For Broaching Machine Set Up Operator

What is broaching?

Broaching is a machining process that uses a broach tool to remove material from a workpiece. Broaching tools have multiple cutting edges that progressively remove material as they are pulled or pushed through the workpiece.

What are the different types of broaching machines?

There are two main types of broaching machines: horizontal and vertical. Horizontal broaching machines are used for broaching holes and slots, while vertical broaching machines are used for broaching external surfaces.

What are the advantages of broaching?

Broaching offers several advantages over other machining processes, including high precision, high production rates, and the ability to produce complex shapes.

What are the challenges of broaching?

The main challenges of broaching are the high cost of broach tools and the need for specialized equipment.

What are the applications of broaching?

Broaching is used in a wide variety of industries, including automotive, aerospace, and medical. It is used to produce a variety of components, including gears, splines, and keyways.