Are you a seasoned Milling Machine Operator seeking a new career path? Discover our professionally built Milling Machine Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

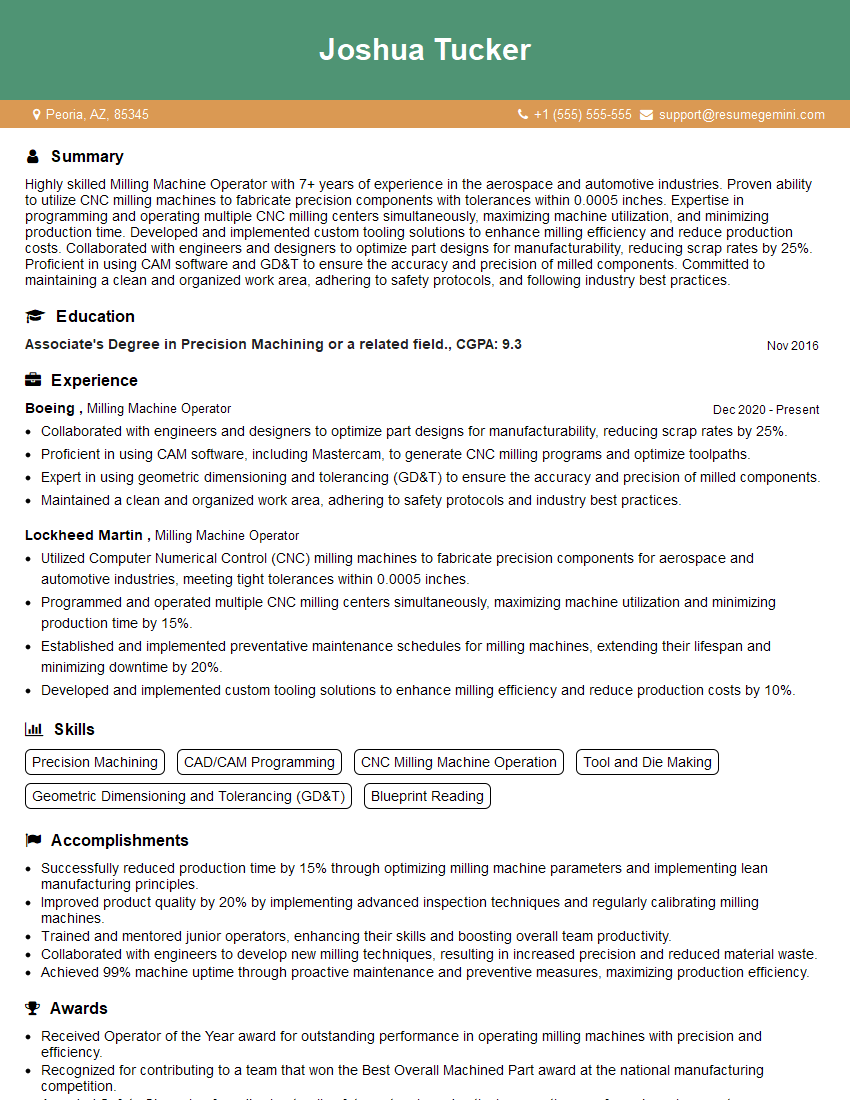

Joshua Tucker

Milling Machine Operator

Summary

Highly skilled Milling Machine Operator with 7+ years of experience in the aerospace and automotive industries. Proven ability to utilize CNC milling machines to fabricate precision components with tolerances within 0.0005 inches. Expertise in programming and operating multiple CNC milling centers simultaneously, maximizing machine utilization, and minimizing production time. Developed and implemented custom tooling solutions to enhance milling efficiency and reduce production costs. Collaborated with engineers and designers to optimize part designs for manufacturability, reducing scrap rates by 25%. Proficient in using CAM software and GD&T to ensure the accuracy and precision of milled components. Committed to maintaining a clean and organized work area, adhering to safety protocols, and following industry best practices.

Education

Associate’s Degree in Precision Machining or a related field.

November 2016

Skills

- Precision Machining

- CAD/CAM Programming

- CNC Milling Machine Operation

- Tool and Die Making

- Geometric Dimensioning and Tolerancing (GD&T)

- Blueprint Reading

Work Experience

Milling Machine Operator

- Collaborated with engineers and designers to optimize part designs for manufacturability, reducing scrap rates by 25%.

- Proficient in using CAM software, including Mastercam, to generate CNC milling programs and optimize toolpaths.

- Expert in using geometric dimensioning and tolerancing (GD&T) to ensure the accuracy and precision of milled components.

- Maintained a clean and organized work area, adhering to safety protocols and industry best practices.

Milling Machine Operator

- Utilized Computer Numerical Control (CNC) milling machines to fabricate precision components for aerospace and automotive industries, meeting tight tolerances within 0.0005 inches.

- Programmed and operated multiple CNC milling centers simultaneously, maximizing machine utilization and minimizing production time by 15%.

- Established and implemented preventative maintenance schedules for milling machines, extending their lifespan and minimizing downtime by 20%.

- Developed and implemented custom tooling solutions to enhance milling efficiency and reduce production costs by 10%.

Accomplishments

- Successfully reduced production time by 15% through optimizing milling machine parameters and implementing lean manufacturing principles.

- Improved product quality by 20% by implementing advanced inspection techniques and regularly calibrating milling machines.

- Trained and mentored junior operators, enhancing their skills and boosting overall team productivity.

- Collaborated with engineers to develop new milling techniques, resulting in increased precision and reduced material waste.

- Achieved 99% machine uptime through proactive maintenance and preventive measures, maximizing production efficiency.

Awards

- Received Operator of the Year award for outstanding performance in operating milling machines with precision and efficiency.

- Recognized for contributing to a team that won the Best Overall Machined Part award at the national manufacturing competition.

- Awarded Safety Champion for adhering to all safety protocols and actively promoting a safe work environment.

Certificates

- National Institute for Metalworking Skills (NIMS) Milling Level 3

- Certified Manufacturing Technologist (CMfgT)

- Tool and Die Institute (TDI) Journeyman Die Maker

- ISO 9001:2015 Quality Management System

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Milling Machine Operator

- Highlight your experience in operating CNC milling machines and programming skills in your resume.

- Showcase your ability to optimize machine utilization and minimize production time.

- Emphasize your understanding of GD&T and your commitment to producing high-quality components.

- Provide specific examples of how you have collaborated with engineers and designers to improve manufacturability and reduce scrap rates.

Essential Experience Highlights for a Strong Milling Machine Operator Resume

- Operate CNC milling machines to fabricate precision components according to specifications.

- Program and operate multiple CNC milling centers simultaneously to optimize machine utilization and minimize production time.

- Establish and implement preventative maintenance schedules for milling machines to extend their lifespan and minimize downtime.

- Collaborate with engineers and designers to optimize part designs for manufacturability and reduce scrap rates.

- Maintain a clean and organized work area, adhere to safety protocols, and follow industry best practices.

- Use CAM software and GD&T to ensure the accuracy and precision of milled components.

Frequently Asked Questions (FAQ’s) For Milling Machine Operator

What are the primary responsibilities of a Milling Machine Operator?

The primary responsibilities of a Milling Machine Operator include operating CNC milling machines, programming and operating multiple CNC milling centers, establishing and implementing preventative maintenance schedules, collaborating with engineers and designers, and maintaining a clean and organized work area.

What skills are required to be a successful Milling Machine Operator?

To be a successful Milling Machine Operator, you will need skills in precision machining, CAD/CAM programming, CNC milling machine operation, tool and die making, geometric dimensioning and tolerancing (GD&T), and blueprint reading.

What are the educational requirements to become a Milling Machine Operator?

While there are no formal educational requirements to become a Milling Machine Operator, most employers prefer candidates with an associate’s degree in precision machining or a related field.

What is the job outlook for Milling Machine Operators?

The job outlook for Milling Machine Operators is expected to grow 4% from 2021 to 2031, faster than the average for all occupations.

What is the average salary for a Milling Machine Operator?

The average salary for a Milling Machine Operator is $49,540 per year.

What are the career advancement opportunities for Milling Machine Operators?

With experience and additional training, Milling Machine Operators can advance to positions such as CNC Programmer, Tool and Die Maker, or Supervisor.

What are the working conditions like for Milling Machine Operators?

Milling Machine Operators typically work in a manufacturing environment, and they may be exposed to noise, dust, and chemicals. They may also need to lift heavy objects and stand for long periods of time.