Are you a seasoned Milling Operator seeking a new career path? Discover our professionally built Milling Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

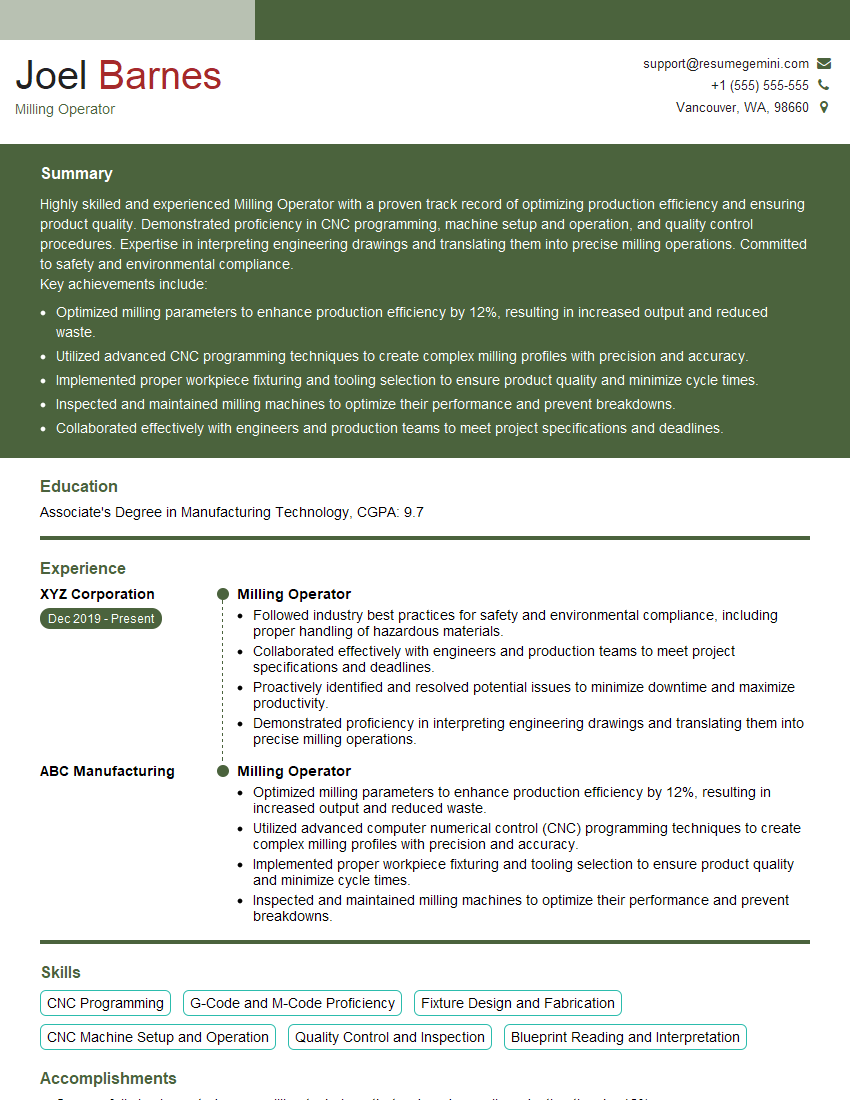

Joel Barnes

Milling Operator

Summary

Highly skilled and experienced Milling Operator with a proven track record of optimizing production efficiency and ensuring product quality. Demonstrated proficiency in CNC programming, machine setup and operation, and quality control procedures. Expertise in interpreting engineering drawings and translating them into precise milling operations. Committed to safety and environmental compliance.

Key achievements include:

- Optimized milling parameters to enhance production efficiency by 12%, resulting in increased output and reduced waste.

- Utilized advanced CNC programming techniques to create complex milling profiles with precision and accuracy.

- Implemented proper workpiece fixturing and tooling selection to ensure product quality and minimize cycle times.

- Inspected and maintained milling machines to optimize their performance and prevent breakdowns.

- Collaborated effectively with engineers and production teams to meet project specifications and deadlines.

Education

Associate’s Degree in Manufacturing Technology

November 2015

Skills

- CNC Programming

- G-Code and M-Code Proficiency

- Fixture Design and Fabrication

- CNC Machine Setup and Operation

- Quality Control and Inspection

- Blueprint Reading and Interpretation

Work Experience

Milling Operator

- Followed industry best practices for safety and environmental compliance, including proper handling of hazardous materials.

- Collaborated effectively with engineers and production teams to meet project specifications and deadlines.

- Proactively identified and resolved potential issues to minimize downtime and maximize productivity.

- Demonstrated proficiency in interpreting engineering drawings and translating them into precise milling operations.

Milling Operator

- Optimized milling parameters to enhance production efficiency by 12%, resulting in increased output and reduced waste.

- Utilized advanced computer numerical control (CNC) programming techniques to create complex milling profiles with precision and accuracy.

- Implemented proper workpiece fixturing and tooling selection to ensure product quality and minimize cycle times.

- Inspected and maintained milling machines to optimize their performance and prevent breakdowns.

Accomplishments

- Successfully implemented a new milling technique that reduced overall production time by 12%

- Trained and mentored five new milling operators, improving their skills and productivity

- Optimized milling parameters to reduce material waste by 8%, resulting in significant cost savings

- Collaborated with engineers to develop a new milling fixture that reduced setup time by 20%

- Successfully troubleshoot and repair complex milling machine issues, minimizing downtime

Awards

- Received the Milling Operator of the Year award for outstanding performance in milling operations

- Recognized for achieving the highest production output among all milling operators in the department

- Received a Certificate of Excellence for exemplary performance in milling operations from the industry association

- Recognized for consistently meeting or exceeding production targets for milling operations

Certificates

- National Institute for Metalworking Skills (NIMS) CNC Milling Level 1

- National Institute for Metalworking Skills (NIMS) CNC Milling Level 2

- American Society for Quality (ASQ) Certified Quality Technician (CQT)

- American Society of Mechanical Engineers (ASME) GD&T Fundamentals

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Milling Operator

- Quantify your accomplishments with specific metrics and data whenever possible.

- Highlight your skills in CNC programming, especially if you have experience with specific software or languages.

- Emphasize your ability to work independently and as part of a team.

- Tailor your resume to each job you apply for, highlighting the skills and experience that are most relevant to the position.

Essential Experience Highlights for a Strong Milling Operator Resume

- Operate and maintain CNC milling machines to produce precision components and parts.

- Interpret engineering drawings and blueprints to determine milling parameters and tooling requirements.

- Set up and fixture workpieces securely to ensure accuracy and prevent damage.

- Select and install appropriate cutting tools and tooling to achieve desired results.

- Monitor milling operations and make adjustments as needed to optimize efficiency and quality.

- Inspect finished parts to ensure they meet specifications and quality standards.

- Perform routine maintenance and repairs on milling machines to maintain optimal performance.

Frequently Asked Questions (FAQ’s) For Milling Operator

What are the educational requirements for a Milling Operator?

Most Milling Operators have a high school diploma or equivalent, although some employers may prefer candidates with an associate’s degree in manufacturing technology or a related field.

What are the key skills required for a Milling Operator?

Key skills for a Milling Operator include proficiency in CNC programming, machine setup and operation, quality control procedures, and blueprint reading. Additionally, strong mechanical aptitude, problem-solving abilities, and attention to detail are essential.

What is the work environment of a Milling Operator like?

Milling Operators typically work in manufacturing facilities, operating CNC milling machines in a fast-paced and often noisy environment. They may work independently or as part of a team, and may need to meet production quotas and deadlines.

What are the career prospects for a Milling Operator?

Milling Operators with experience and additional skills, such as programming or maintenance, may have opportunities for advancement to positions such as CNC Programmer, Machinist, or Production Supervisor.

What is the average salary for a Milling Operator?

The average salary for a Milling Operator in the United States is around $45,000 per year, although salaries can vary depending on experience, location, and industry.

What are the safety precautions that Milling Operators should take?

Milling Operators should always wear appropriate safety gear, including safety glasses, gloves, and earplugs, and follow established safety procedures to minimize the risk of injury.

How can I improve my skills as a Milling Operator?

To improve your skills as a Milling Operator, you can take additional training courses in CNC programming, machine operation, or quality control. Additionally, seeking opportunities to work on complex projects or with experienced mentors can help you develop your abilities.