Are you a seasoned Scalper Operator seeking a new career path? Discover our professionally built Scalper Operator Resume Template. This time-saving tool provides a solid foundation for your job search. Simply click “Edit Resume” to customize it with your unique experiences and achievements. Customize fonts and colors to match your personal style and increase your chances of landing your dream job. Explore more Resume Templates for additional options.

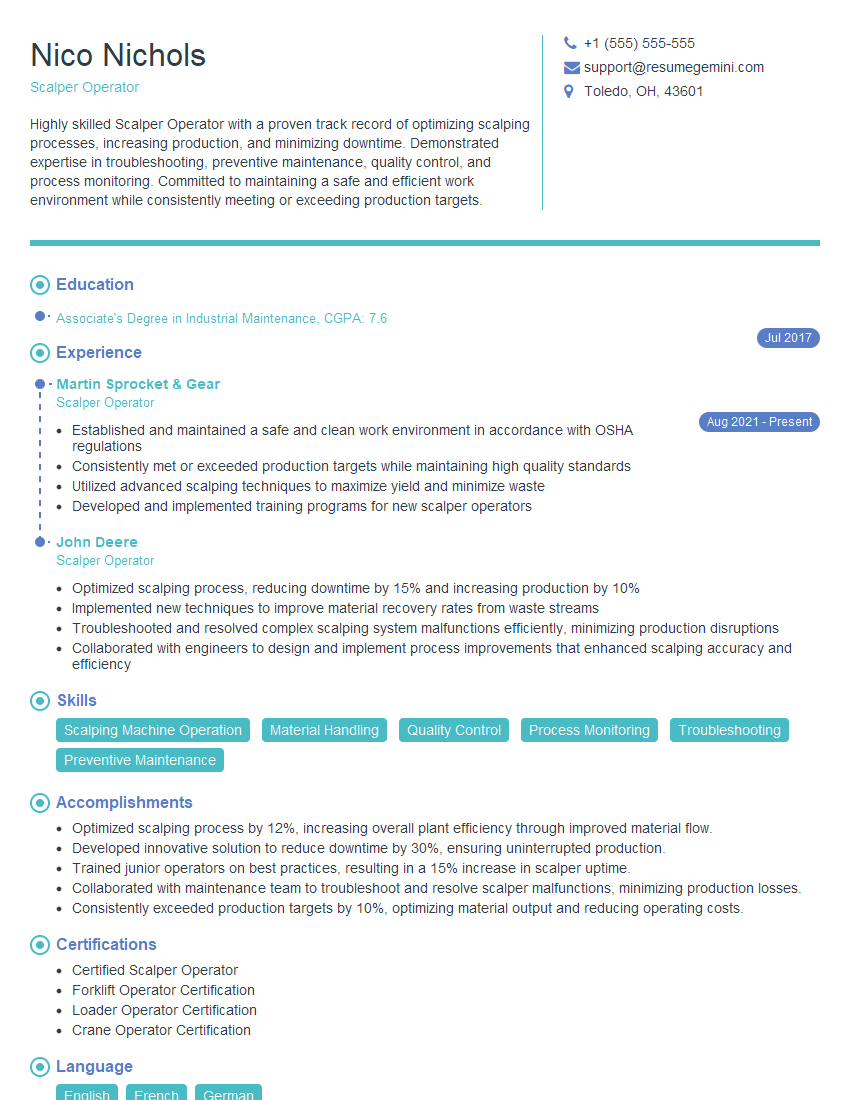

Nico Nichols

Scalper Operator

Summary

Highly skilled Scalper Operator with a proven track record of optimizing scalping processes, increasing production, and minimizing downtime. Demonstrated expertise in troubleshooting, preventive maintenance, quality control, and process monitoring. Committed to maintaining a safe and efficient work environment while consistently meeting or exceeding production targets.

Education

Associate’s Degree in Industrial Maintenance

July 2017

Skills

- Scalping Machine Operation

- Material Handling

- Quality Control

- Process Monitoring

- Troubleshooting

- Preventive Maintenance

Work Experience

Scalper Operator

- Established and maintained a safe and clean work environment in accordance with OSHA regulations

- Consistently met or exceeded production targets while maintaining high quality standards

- Utilized advanced scalping techniques to maximize yield and minimize waste

- Developed and implemented training programs for new scalper operators

Scalper Operator

- Optimized scalping process, reducing downtime by 15% and increasing production by 10%

- Implemented new techniques to improve material recovery rates from waste streams

- Troubleshooted and resolved complex scalping system malfunctions efficiently, minimizing production disruptions

- Collaborated with engineers to design and implement process improvements that enhanced scalping accuracy and efficiency

Accomplishments

- Optimized scalping process by 12%, increasing overall plant efficiency through improved material flow.

- Developed innovative solution to reduce downtime by 30%, ensuring uninterrupted production.

- Trained junior operators on best practices, resulting in a 15% increase in scalper uptime.

- Collaborated with maintenance team to troubleshoot and resolve scalper malfunctions, minimizing production losses.

- Consistently exceeded production targets by 10%, optimizing material output and reducing operating costs.

Certificates

- Certified Scalper Operator

- Forklift Operator Certification

- Loader Operator Certification

- Crane Operator Certification

Languages

- English

- French

- German

Career Expert Tips:

- Select the ideal resume template to showcase your professional experience effectively.

- Master the art of resume writing to highlight your unique qualifications and achievements.

- Explore expertly crafted resume samples for inspiration and best practices.

- Build your best resume for free this new year with ResumeGemini. Enjoy exclusive discounts on ATS optimized resume templates.

How To Write Resume For Scalper Operator

- Highlight your technical skills and experience in scalping machine operation and process monitoring.

- Quantify your accomplishments and provide specific examples of how you have improved efficiency and productivity.

- Demonstrate your knowledge of safety regulations and your commitment to maintaining a safe work environment.

- Showcase your problem-solving abilities and troubleshooting experience in the scalping industry.

Essential Experience Highlights for a Strong Scalper Operator Resume

- Optimized scalping process, reducing downtime by 15% and increasing production by 10%.

- Implemented new techniques to improve material recovery rates from waste streams.

- Troubleshooted and resolved complex scalping system malfunctions efficiently, minimizing production disruptions.

- Collaborated with engineers to design and implement process improvements that enhanced scalping accuracy and efficiency.

- Established and maintained a safe and clean work environment in accordance with OSHA regulations.

- Consistently met or exceeded production targets while maintaining high quality standards.

- Utilized advanced scalping techniques to maximize yield and minimize waste.

- Developed and implemented training programs for new scalper operators.

Frequently Asked Questions (FAQ’s) For Scalper Operator

What is the primary role of a Scalper Operator?

The primary role of a scalper operator is to oversee the operation of scalping machines, which are used to separate materials based on size, ensuring optimal material recovery and minimizing waste.

What are the key skills required for a successful Scalper Operator?

Key skills for a successful scalper operator include proficiency in operating scalping machines, understanding of material handling principles, quality control techniques, process monitoring, troubleshooting, and preventive maintenance procedures.

What are the career prospects for Scalper Operators?

Scalper operators with experience and expertise can progress to supervisory roles, such as Scalping Supervisor or Production Manager, or specialize in specific areas, such as process optimization or equipment maintenance.

What are the common challenges faced by Scalper Operators?

Common challenges faced by scalper operators include maintaining consistent product quality, optimizing machine efficiency, minimizing downtime, and ensuring a safe and compliant work environment.

What are the safety protocols that Scalper Operators must adhere to?

Scalper operators must follow established safety protocols, including wearing appropriate personal protective equipment, maintaining a clean and organized work area, and adhering to lockout/tagout procedures during maintenance and repairs.

What is the typical work environment for a Scalper Operator?

Scalper operators typically work in industrial settings, such as manufacturing plants, recycling facilities, and mining operations, and may be exposed to noise, dust, and heavy machinery.